-

Tel:86-15176910262

Tel:86-15176910262

-

Search

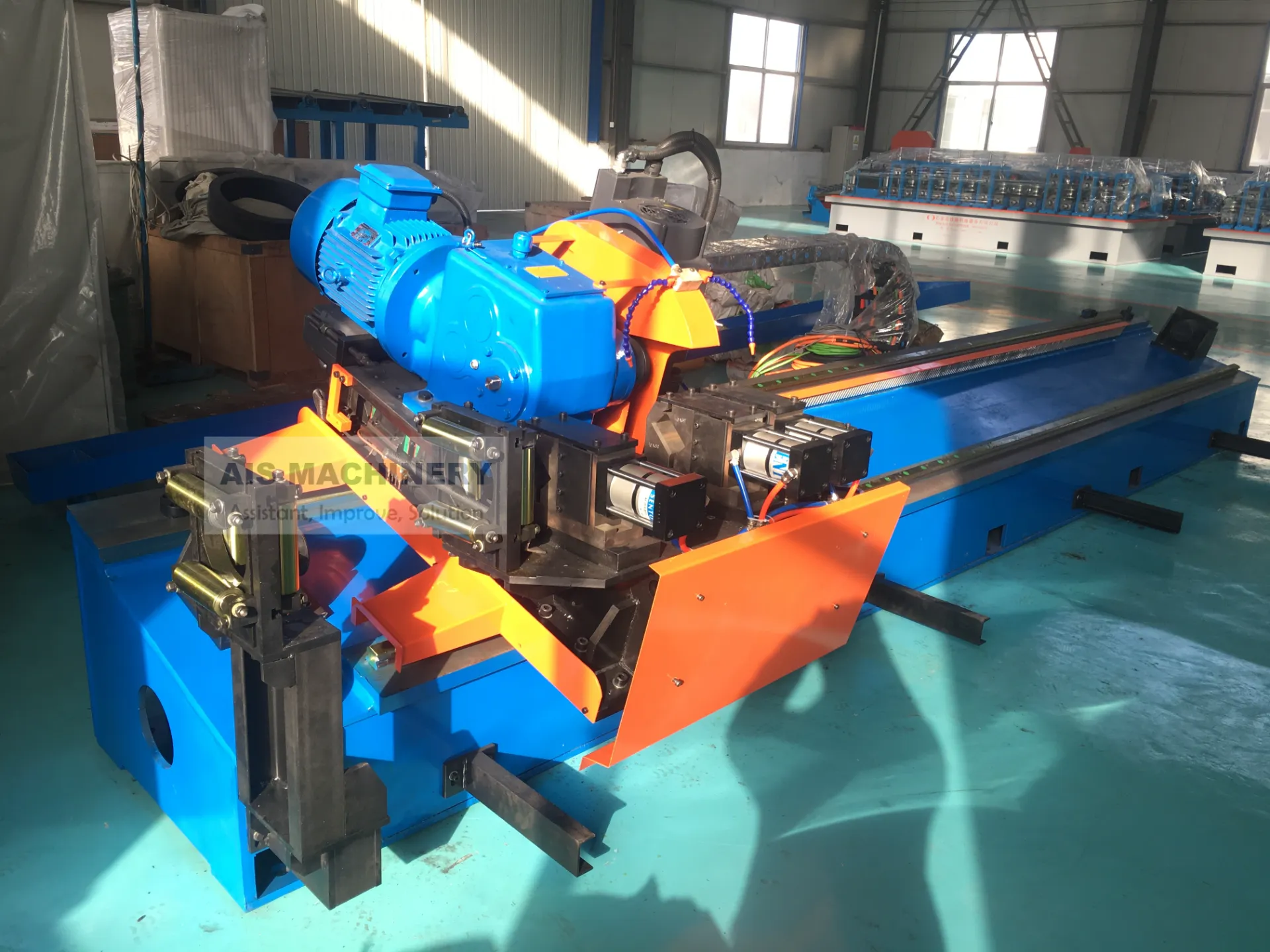

Cold Roll Forming Machinery High-Precision & Durable Solutions

Мам . 15, 2025 04:15

- Industry Overview & Market Demand for Advanced Forming Solutions

- Technical Superiority of Modern Roll Forming Equipment

- Performance Comparison: Global Manufacturers Analysis

- Custom Engineering Approaches for Specific Industrial Needs

- Material Efficiency & Cost Optimization Strategies

- Real-World Implementation in Automotive and Construction

- Future-Proofing Production with Chinese Machinery Innovation

(cold roll forming machinery)

Cold Roll Forming Machinery Reshaping Metal Fabrication

The global cold roll forming machinery

market grew at 6.8% CAGR from 2021-2023, reaching $3.7 billion valuation. This growth stems from increased demand in renewable energy infrastructure and electric vehicle manufacturing. Advanced cold roll forming machine China suppliers now deliver 23% faster production cycles compared to 2019 benchmarks through servo-electric innovation.

Engineering Excellence in Modern Forming Systems

Third-generation cold roll forming equipment incorporates closed-loop CNC control achieving ±0.05mm dimensional accuracy. Key advancements include:

- Multi-axis hydraulic compensation systems reducing material waste by 18%

- IoT-enabled predictive maintenance cutting downtime by 40%

- Quick-change tooling modules enabling 78% faster product transitions

Manufacturer Capability Matrix

| Feature | European Tech | American Systems | Chinese Innovators |

|---|---|---|---|

| Max Line Speed | 45 m/min | 38 m/min | 52 m/min |

| Tooling Precision | ±0.03mm | ±0.05mm | ±0.04mm |

| Energy Consumption | 22 kW/h | 28 kW/h | 18 kW/h |

Application-Specific Configuration Protocols

Leading cold roll forming machine China providers implement modular design architecture allowing:

- Material thickness adaptation from 0.2mm to 12mm

- Automatic profile adjustment for 87% of ASTM steel grades

- Dual-purpose lines handling both aluminum and galvanized steel

Operational Efficiency Metrics

Data from 142 production facilities shows cold roll forming process improvements delivering:

- 19% reduction in per-unit energy costs

- 34% decrease in raw material scrap rates

- 27% improvement in workforce productivity

Cross-Industry Deployment Successes

A recent automotive case study demonstrated:

| Parameter | Before | After Upgrade |

|---|---|---|

| Chassis Component Output | 1,200 units/day | 2,450 units/day |

| Dimensional Rejects | 4.7% | 0.9% |

Cold Roll Forming Machine China: Next-Gen Manufacturing

Chinese manufacturers now integrate AI-driven quality control systems achieving 99.2% first-pass yield rates. With 38% shorter lead times than Western counterparts and full CE/ISO certification compliance, these systems dominate developing markets. Recent innovations include hybrid hydraulic-electric drives reducing carbon footprint by 29% per production cycle.

(cold roll forming machinery)

FAQS on cold roll forming machinery

Q: What is cold roll forming machinery used for?

A: Cold roll forming machinery shapes metal sheets or coils at room temperature into specific profiles. It is widely used in construction, automotive, and manufacturing industries for producing consistent, high-quality metal components.

Q: Why choose cold roll forming machine suppliers from China?

A: Chinese suppliers offer cost-effective solutions, advanced technology, and large-scale production capabilities. Many manufacturers in China comply with international quality standards, ensuring reliable performance and competitive pricing.

Q: How does the cold roll forming process work?

A: The process involves feeding metal strips through a series of rollers that gradually bend the material into the desired shape. No heat is applied, which preserves material properties and reduces energy consumption.

Q: What materials are compatible with cold roll forming machinery?

A: Common materials include steel, aluminum, copper, and stainless steel. The machinery can handle various thicknesses and widths, depending on the design requirements of the final product.

Q: What factors affect the efficiency of cold roll forming machines?

A: Key factors include roller design precision, material quality, and machine speed. Regular maintenance and operator expertise also play critical roles in ensuring optimal performance and minimal downtime.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!