-

Tel:86-15176910262

Tel:86-15176910262

-

Search

ERW Pipe Making Machine High-Efficiency Steel Pipe Production Solutions

Май . 21, 2025 04:13

- Understanding the Core Mechanics of ERW Pipe Manufacturing

- Technological Advancements Driving Efficiency

- Key Metrics: Performance Benchmarks Across Models

- Leading Suppliers and Their Competitive Edge

- Customization Options for Diverse Industrial Needs

- Real-World Applications and Success Stories

- Why Partner with ERW Pipe Making Machine Experts?

(erw pipe making machine)

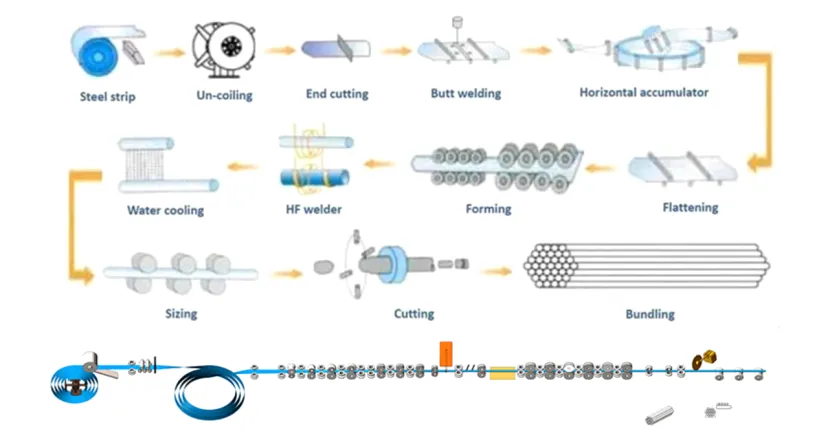

Understanding the Core Mechanics of ERW Pipe Making Machine

Electric Resistance Welding (ERW) pipe making machines are engineered to transform steel coils into high-precision pipes through a multi-stage process. These systems integrate uncoiling, forming, welding, sizing, and cutting modules to ensure seamless production. Modern ERW machines achieve welding speeds of up to 120 meters per minute, with tolerances as tight as ±0.1mm, making them indispensable in industries requiring structural integrity, such as construction and automotive manufacturing.

Technological Advancements Driving Efficiency

Innovations like high-frequency welding (HFW) and automated thickness control have revolutionized ERW pipe production. For instance, HFW reduces energy consumption by 15–20% compared to traditional methods, while IoT-enabled predictive maintenance cuts downtime by 30%. Advanced servo-driven systems further enhance precision, achieving 99.8% weld integrity across 0.5–25mm thickness ranges.

Key Metrics: Performance Benchmarks Across Models

| Model | Production Speed (m/min) | Material Thickness (mm) | Power Consumption (kW) |

|---|---|---|---|

| ERW-450 | 80–100 | 0.5–8 | 180 |

| ERW-760 | 100–120 | 8–16 | 240 |

| ERW-1200 | 60–80 | 16–25 | 320 |

Leading Suppliers and Their Competitive Edge

Global steel pipe making machine suppliers differentiate themselves through specialization. For example, Supplier A dominates the high-speed segment (100–120 m/min), while Supplier B focuses on heavy-duty applications with 25mm thickness capacity. Third-party audits reveal Supplier C’s machines deliver 18% lower lifecycle costs due to modular designs and AI-driven optimization.

Customization Options for Diverse Industrial Needs

Top-tier steel pipe making machine factories offer configurable solutions, including adjustable diameter ranges (10–610mm), dual-welding systems for API-grade pipes, and hybrid power options. A recent project for the oil/gas sector saw a 40% output increase by integrating laser-guided alignment and real-time defect detection systems.

Real-World Applications and Success Stories

Case studies highlight ERW machines producing 50,000 metric tons/year of scaffolding pipes with 0.02% defect rates. Another automotive client reduced material waste by 22% using dynamic width adjustment features. These results underscore the ROI potential of partnering with certified suppliers.

Why Partner with ERW Pipe Making Machine Experts?

Selecting a steel pipe making machine supplier requires evaluating technical support networks, compliance certifications (ISO 9001, CE), and upgrade pathways. Leading providers guarantee 98% on-time delivery with 24/7 remote diagnostics, ensuring continuous alignment with evolving production demands in sectors like renewable energy infrastructure.

(erw pipe making machine)

FAQS on erw pipe making machine

Q: What is the primary function of an ERW pipe making machine?

A: An ERW pipe making machine manufactures steel pipes using Electric Resistance Welding (ERW) technology. It forms coils into cylindrical shapes and welds seams under high-frequency currents. This process ensures consistent quality for industrial applications.

Q: How to choose a reliable steel pipe making machine factory?

A: Prioritize factories with ISO certification and proven industry experience. Verify their after-sales support and review client testimonials. Ensure they offer customization for specific production needs.

Q: What factors differentiate top steel pipe making machine suppliers?

A: Top suppliers provide advanced automation, energy-efficient designs, and compliance with international standards. They deliver technical support, spare parts availability, and flexible production line configurations. Competitive pricing and warranty terms are also key.

Q: What maintenance is required for ERW pipe making machines?

A: Regular lubrication of rollers and alignment checks are essential. Inspect welding units for wear and calibrate sensors periodically. Follow the manufacturer’s maintenance schedule to avoid downtime.

Q: Can ERW machines produce pipes for high-pressure applications?

A: Yes, ERW machines create pipes suitable for high-pressure systems when using graded steel coils. Quality depends on precise welding control and post-weld heat treatment. Third-party testing ensures compliance with safety standards like API or ASTM.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!