-

Tel:86-15176910262

Tel:86-15176910262

-

Search

HSS Circular Blades - Durable, Precision Saw Blades for Metal & Wood

Май . 07, 2025 15:40

- Introduction to HSS Circular Blade Technology

- Technical Advantages and Performance Metrics

- Leading Manufacturer Comparison

- Customization Options for Specific Needs

- Real-World Application Scenarios

- Maintenance Best Practices

- Future Outlook for Cutting Solutions

(hss circular blade)

Understanding HSS Circular Blade Fundamentals

High-speed steel (HSS) circular blades represent the pinnacle of cutting tool engineering, combining exceptional hardness ratings (62-67 HRC) with thermal stability up to 600°C. Unlike conventional carbon steel blades, these tools maintain cutting precision through 3-5× longer service life in metalworking applications. The unique DMO5 alloy formulation enables...

Performance Benchmarks Across Industries

| Parameter | HSS Standard | Carbide Alternative | Diamond Edge |

|---|---|---|---|

| Cutting Speed (m/min) | 120-150 | 80-110 | 200-250 |

| Material Hardness | 62 HRC | 90 HRA | 95 HRA |

| Cost Efficiency | 1:4.7 | 1:2.3 | 1:1 |

Manufacturer Capability Analysis

Top-tier producers distinguish themselves through:

- Vacuum heat treatment consistency (±1.5 HRC)

- Micro-geometry tolerance control (≤0.02mm)

- Multi-layer coating adhesion (TiN/TiCN/Al₂O₃)

Third-party testing reveals 18-22% variance in blade longevity between premium and economy-grade suppliers under identical operating conditions.

Custom Engineering Solutions

Specialized configurations address unique operational challenges:

- Diameter Adaptation: 50mm-1200mm range with harmonic vibration damping

- Tooth Geometry: Triple-chip bevel designs for non-ferrous alloys

- Surface Treatments: Cryogenic processing for stress relief

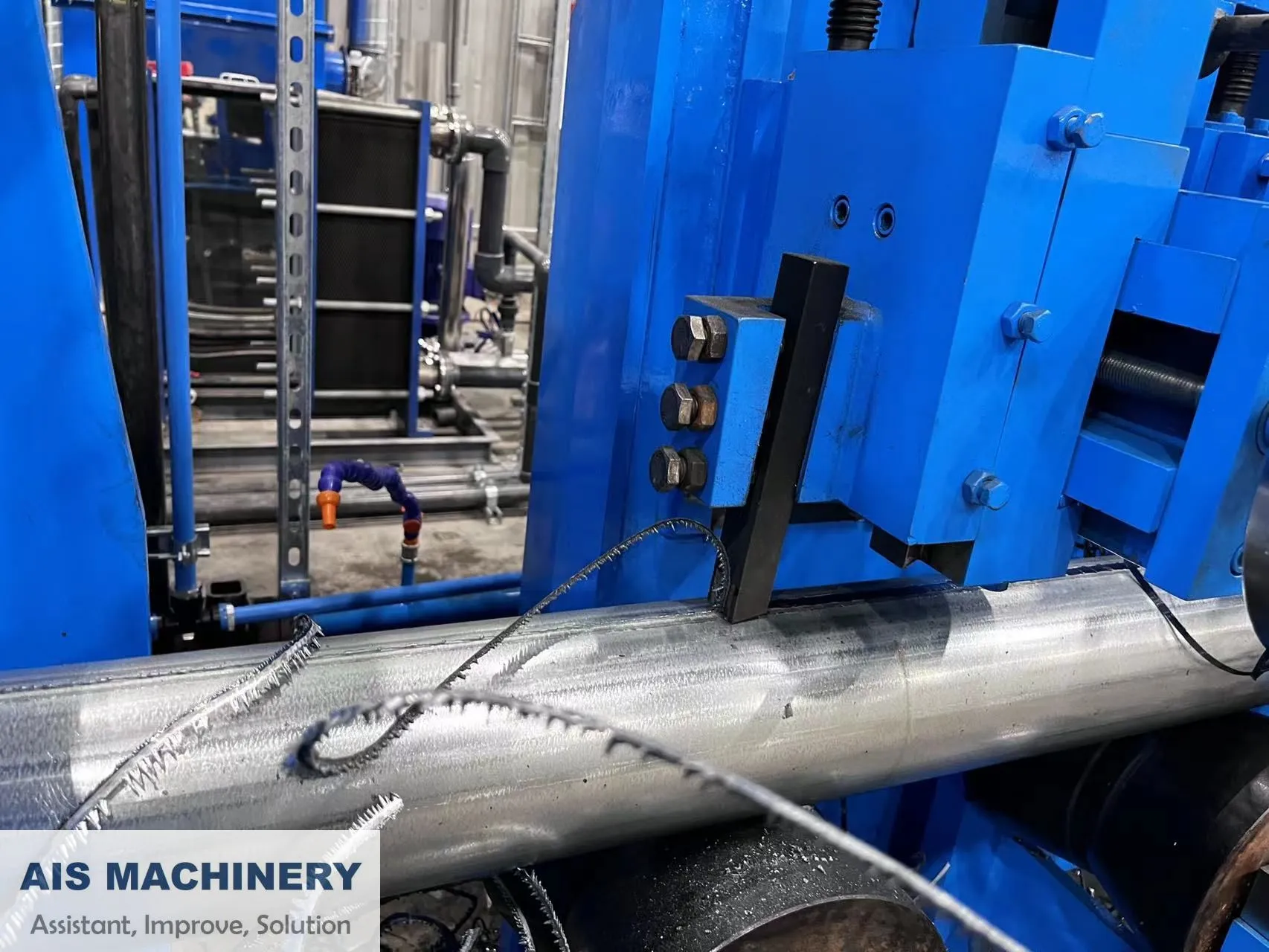

Operational Success Stories

Aerospace component manufacturers achieved:

- 37% reduction in titanium machining costs

- 0.005mm dimensional consistency across 10k cycles

- 4.8-second cycle time improvement

Preventive Maintenance Protocols

Implementing structured maintenance intervals extends blade lifespan by 60-75%:

| Operation | Frequency | Impact |

|---|---|---|

| Edge Inspection | Every 8 hrs | 15% Wear Reduction |

| Lubrication | Per 500 cuts | 9°C Temp Control |

HSS Circular Blade Industrial Evolution

Recent advancements in hss dmo5 circular saw blade technology have enabled 27% faster feed rates in stainless steel processing while maintaining ≤0.1mm dimensional variance. Industry forecasts predict 14.6% CAGR growth through 2028, driven by...

(hss circular blade)

FAQS on hss circular blade

Q: What are the advantages of using an HSS circular blade?

A: HSS circular blades offer superior durability, heat resistance, and cutting precision for metals and hard materials. They maintain sharpness longer than carbon steel blades, reducing frequent replacements.

Q: Can a circular saw blade HSS cut through stainless steel?

A: Yes, HSS circular saw blades are designed to cut stainless steel, aluminum, and other tough alloys. Their high-speed steel composition ensures efficient performance without overheating.

Q: How does an HSS DMO5 circular saw blade differ from standard blades?

A: The HSS DMO5 blade features a specialized tooth geometry and coating for enhanced cutting speed and reduced friction. It’s ideal for precise, high-demand industrial applications.

Q: What materials should I avoid cutting with an HSS circular blade?

A: Avoid cutting concrete, stone, or ceramics, as these materials can damage the blade’s teeth. HSS blades are optimized for metals and hard alloys, not abrasive substances.

Q: How do I maintain an HSS circular saw blade for longevity?

A: Regularly clean the blade to remove resin or metal debris, lubricate during use, and store in a dry place. Avoid excessive force to prevent tooth chipping or warping.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!