-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Tube Mill Design Solutions - High Efficiency & Competitive ERW Tube Mill Price

Июл . 08, 2025 04:11

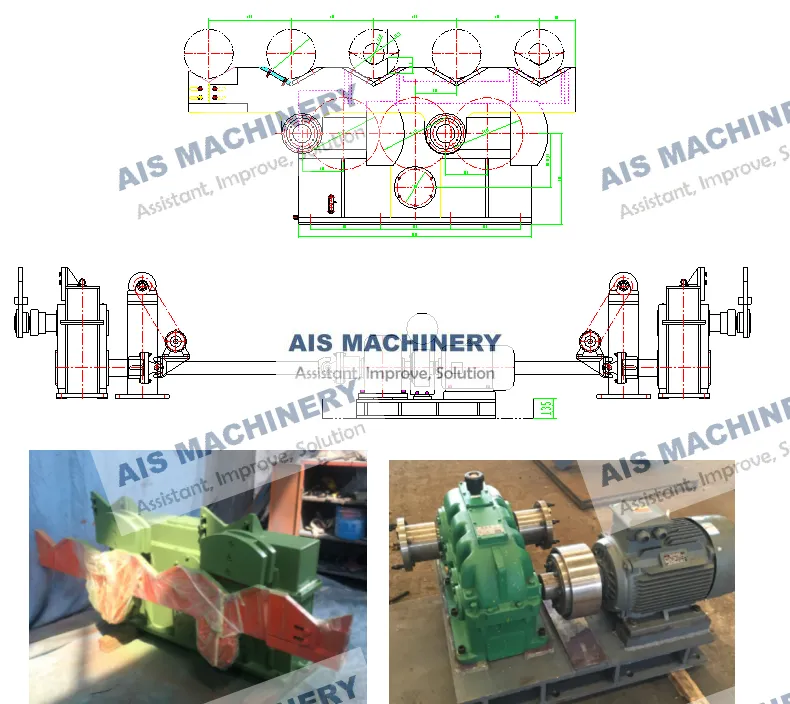

- Introduction to tube mill design

and its industrial significance - Data-driven insights and technical innovations in tube mill technologies

- Comparative analysis of leading tube mill manufacturers with pricing insights

- Customization and tailored solutions in modern tube mill engineering

- Case studies highlighting tube mill design applications across sectors

- Strategic considerations for investment and future-readiness

- Conclusion: Elevating manufacturing with advanced tube mill design

(tube mill design)

Introduction: Industrial Impact of Tube Mill Design

In modern manufacturing, tube mill design stands at the intersection of efficiency, durability, and scalable output. Tube mills serve as critical assets in producing seamless and welded tubes for industries ranging from automotive and construction to energy and furniture. Over 60% of global tube production relies on well-engineered mill systems—highlighting their pivotal role. As production requirements have grown in complexity, so too has the need for smarter, more flexible tube mill design solutions that balance cost-effectiveness with uncompromising quality. Flawless tube output, minimized scrap rates, and streamlined changeovers are now essential benchmarks for mill operators worldwide.

Technological Advancements and Performance Data

The transition from basic mechanical setups to intelligent, digitally integrated tube mills has revolutionized manufacturing processes. Leading-edge systems now incorporate servo-driven roll stands, advanced Human-Machine Interfaces (HMIs), and Industry 4.0 analytics. For instance, modern tube mills achieve average line speeds up to 120 meters per minute, while keeping wall thickness variability within ±0.02 mm. Automated quick-change tooling reduces downtime by up to 70%, compared to traditional manual methods. The following data table presents a comparative overview of legacy and state-of-the-art tube mill technologies:

| Specification | Legacy Tube Mills | Advanced Tube Mills |

|---|---|---|

| Max. Line Speed (m/min) | 50–60 | 100–140 |

| Tube Diameter Range (mm) | 10–76 | 8–168 |

| Wall Thickness Tolerance (mm) | ±0.1 | ±0.02 |

| Changeover Time (minutes) | 180–300 | 40–90 |

| Maintenance Frequency | Every 400 hours | Every 1200 hours |

| Digital Integration | Manual operation | Full PLC + HMI |

These innovations are not mere technical upgrades—they drive measurable ROI. Plants upgrading to new-generation mills report 30% lower energy consumption and 25% reductions in scrap rates, revealing the importance of continual investment in next-level tube mill design.

Manufacturer Comparison and Price Analysis

The tube mill market comprises both established global brands and agile regional suppliers. Apart from technical credentials, considerations such as tube mill price and after-sales support heavily influence procurement strategies. Leading manufacturers like Fives (France), Yoder (USA), and Chinese powerhouses like HG and Sunfone offer diverse portfolios for ERW (Electric Resistance Welded) and seamless tube mill lines. The following comparison provides an at-a-glance evaluation of major factory sources and erw tube mill price trends:

| Manufacturer | Country | Technology Focus | Price Range (USD) | Warranty (years) | Lead Time (weeks) |

|---|---|---|---|---|---|

| Fives | France | Full automation, high precision | 900,000–2,500,000 | 2–3 | 32–44 |

| Yoder | USA | Flexible, heavy gauge | 950,000–2,300,000 | 2 | 35–50 |

| HG | China | Cost-effective, adaptive sizing | 270,000–890,000 | 1 | 15–26 |

| Sunfone | Taiwan | Quick-change, mid gauge | 360,000–1,120,000 | 1.5 | 20–30 |

These pricing figures reflect turnkey project scopes, including installation and commissioning. Notably, Asian suppliers are closing the gap in technology while maintaining a significant cost advantage—erw tube mill price from these sources is often 30–50% lower than their Western counterparts, especially for small to medium-diameter ranges.

Customization and Modern Engineering Solutions

Flexibility is the new imperative for competitive mills. Custom-engineered tube mill systems are tailored to unique substrate types, throughput expectations, and end-product specifications. This customization extends not only to forming stands and cutoff machines but also to full integration with downstream processes like galvanizing, painting, or in-line testing. Operators can specify parameters such as automatic coil handling, motorized adjustment mechanisms, and multi-size tooling setups, each engineered for minimal manual intervention. The capacity to granularly configure your mill translates to faster project turnarounds and exquisite product consistency—features that drive exponential value for specialized sectors such as gas line piping or high-tolerance automotive components.

Real-World Applications: Case Study Review

Across industries, high-quality tube mill systems have demonstrated their versatility. A German automotive supply chain recently partnered with a Taiwanese mill maker to retrofit existing lines with servo-positioning and vision-based inspection, reducing defect rates to below 0.4%. In building construction, multiple firms utilize high-speed ERW tube mills to manufacture scaffolding pipes and structural beams, achieving annual outputs exceeding 80,000 metric tons per facility. Another notable case saw a leading HVAC tube producer adopt a rapid diameter-changing line, cutting production switchover times by 65% and supporting custom tube orders for over 60 clients globally. These real-world deployments exemplify the return on investment achievable by aligning tube mill design capabilities with market needs.

Strategic Insights for Tube Mill Investment

Decision-makers aiming to optimize capex allocations must weigh operational requirements against market dynamics. Incorporating digital monitoring and preventative maintenance planning can extend asset lifespan by up to 50%. When evaluating a new or replacement mill, factors such as utility costs, operator skill level, and line adaptability to new alloys or standards are paramount. Recent studies suggest that manufacturers leveraging smart tube mill data analytics report yield gains of 12–17% within the first operational year. Choosing a platform that facilitates easy future expansion ensures that production remains resilient amid shifting industry trends.

Conclusion: Manufacturing Excellence with Tube Mill Design

As global industries demand higher throughput and precision, advanced tube mill design continues to set new performance benchmarks. Through the integration of intelligent controls, adaptable engineering, and robust quality assurance, companies equipped with state-of-the-art tube mills are positioned to outperform across product categories and markets. Whether driven by cost optimization, production flexibility, or stringent regulatory demands, investing in innovative tube mill solutions is a decisive lever for growth and sustained competitiveness.

(tube mill design)

FAQS on tube mill design

Q: What is tube mill design?

A: Tube mill design refers to the engineering and layout of machinery used to manufacture metal tubes and pipes. It includes aspects like forming, welding, sizing, and cutting. A well-designed tube mill improves efficiency and product quality.Q: How does tube mill design affect tube mill price?

A: Advanced tube mill design usually incorporates automation and high-quality materials, which can increase the initial price. However, it can reduce long-term operating costs and boost production speed. Better designs often lead to a higher tube mill price up front, but better value over time.Q: What factors influence erw tube mill price?

A: The price of an ERW tube mill depends on its design complexity, production capacity, and included features. Enhanced automation and precision components raise costs. Market demand and brand reputation are also key factors.Q: Can tube mill design be customized for specific production needs?

A: Yes, tube mill design can be tailored to produce specific tube shapes, sizes, and materials. Customization may affect both function and price. Manufacturers often consult with buyers to create optimal solutions.Q: Why should I consider both tube mill design and price before purchasing?

A: Evaluating both design and price ensures you get machinery that matches your production requirements and budget. A higher tube mill price might provide better performance and lower maintenance costs. Balancing both helps maximize your investment.Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!