Опис товару

✅ 1. Product Overview

The Pipe Threading Machine is a specialized machine used to cut internal or external threads on the ends of metal pipes. It is widely used in industries such as pipeline manufacturing, oil & gas, construction, and firefighting systems. It supports various thread types including NPT, BSPT, API, and straight threads.

✅ 2. Product Details

-

Product Name: Pipe Threading Machine

-

Functions: External thread, internal thread, tapered (NPT/BSPT/API) or straight thread processing

-

Materials Supported: Round pipes, black pipes, galvanized pipes, seamless steel, stainless steel

-

Standards Supported: API, DIN, BS, GB, etc.

-

Control Type: Manual / Semi-automatic / CNC

✅ 3. Main Components

-

Machine Bed – Provides structural stability

-

Chuck – 3-jaw or 4-jaw type to clamp and hold pipes

-

Spindle Unit – Rotates either the pipe or the cutting tool

-

Tool Post – Holds threading tools or roller heads

-

Feeding System – Manual or automatic advancement of the cutting tool

-

Cooling System – Keeps cutting area cool, extends tool life

-

Control Panel – Controls rotation, feed speed, and threading parameters

✅ 4. Technical Specifications

| Item |

Specification |

| Pipe Diameter Range |

1/2"–6" (optional up to 8"+ on request) |

| Max Thread Length |

300–600 mm |

| Spindle Speed |

20–300 rpm (stepless or stepped adjustment) |

| Motor Power |

3–11 kW (varies by model) |

| Thread Types Supported |

NPT, BSPT, API, BSPP, G, RC, etc. |

| Control System |

Manual / Semi-automatic / CNC |

| Thread Accuracy |

Pitch tolerance ≤ ±0.05 mm |

| Cooling System |

Circulating or mist cooling |

✅ 5. Working Principle

-

The pipe is clamped by the chuck and rotated (or the tool rotates);

-

The tool feeds along the pipe axis via feed mechanism;

-

The cutting tool creates threads according to set parameters;

-

After threading, the tool retracts automatically or manually;

-

Cooling system minimizes thermal deformation and extends tool life.

✅ 6. Application Scenarios

-

⛽ Oil & Gas: API casing and drill pipe threading

-

🚰 Water Supply & Drainage: Galvanized and black steel pipe threading

-

🔥 Fire Protection Systems: Firefighting pipe threading

-

🏗️ Construction: Electrical conduit and HVAC pipe threading

-

⚙️ Hardware Workshops: Custom batch thread cutting

✅ 7. User Feedback Summary

-

⭐ High Precision: Threads are smooth and meet international standards

-

🔄 Easy to Operate: Especially CNC versions with user-friendly interface

-

🧰 Low Maintenance: Modular design for quick part replacement

-

⏱️ Efficient: Short processing cycles, ideal for batch work

-

💰 Cost-Effective: Local machines offer good performance-to-price ratio

-

⚠️ User Tip: Change tools regularly during heavy-duty operation to maintain quality

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Вихрострумова машина

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

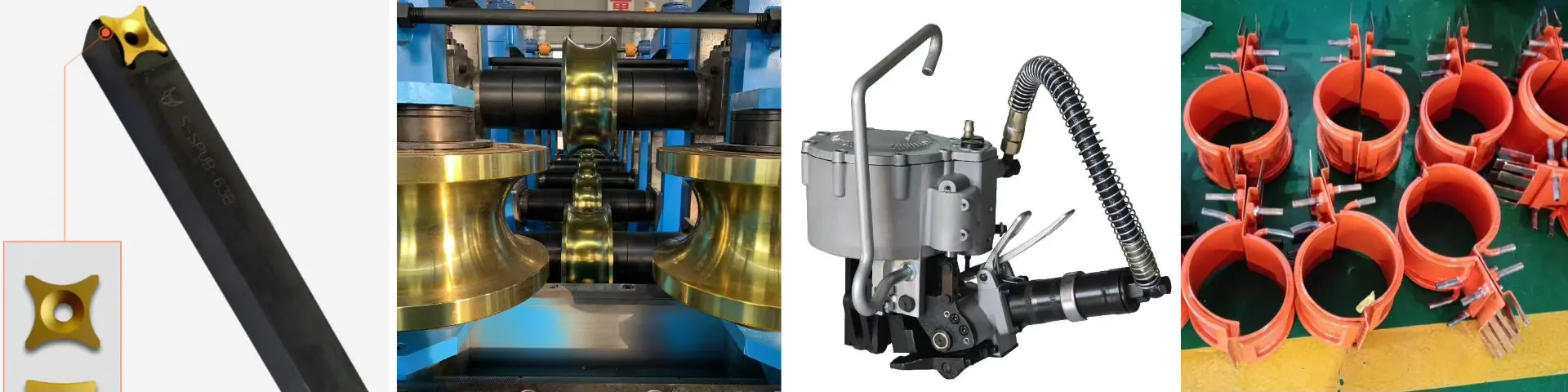

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Чому обирають нас?

-

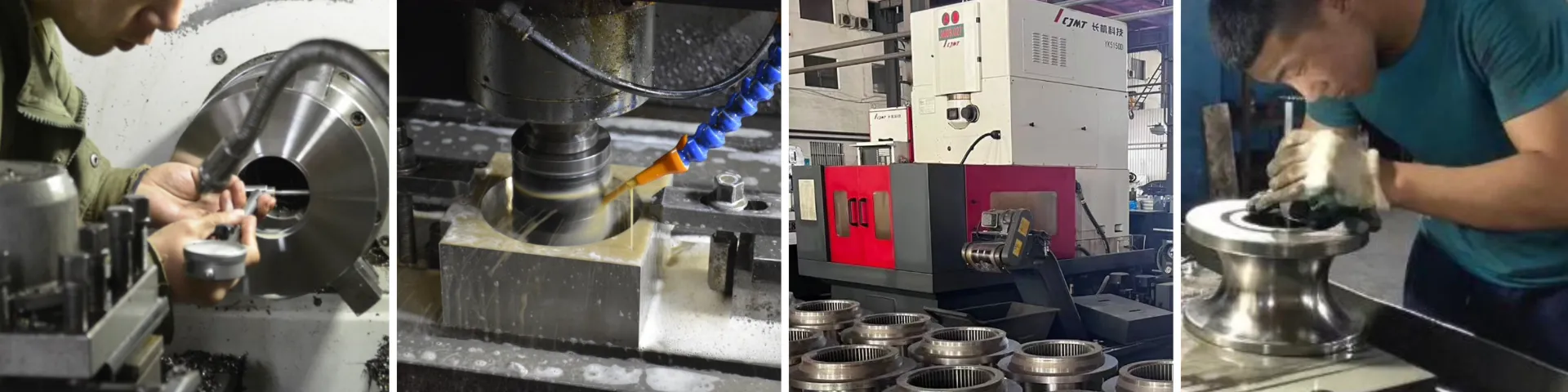

1.Leading Technology, Reliable Quality, Excellent Service! Оптимізований дизайн, вибір високоякісних матеріалів! Гарантія процесу термічної обробки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Загартування зубів шестерень. Привідна система стабільна, ефективна та придатна до носіння з низьким рівнем шуму.

-

3.High precision wear resisting and Long life of toolings. Усі токарні верстати, шпонкові канавки позиціонуються та фрезеруються за допомогою ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Післяпродажне обслуговування

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5.24 години для відповіді інженера.

- 6. Ваші ділові відносини з нами будуть конфіденційними для будь-якої третьої сторони.

- 7. We welcome customers to visit our factory anytime.

Тел.: 86-15176910262

Тел.: 86-15176910262