-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Efficiency ERW Pipe Mill with GPT-4 Turbo AI

Avg . 04, 2025 11:20

Industry Trends: The Ascent of ERW Pipe Mill Technology

- Global ERW (Electric Resistance Welded) pipe demand rose by 6.3% CAGR between 2017-2023 (Source: Grand View Research, link).

- Modern erw pipe making machine technology now achieves line speeds of up to 120m/min with strict ISO and API compliance.

- Sustainability is driving demand for energy-efficient, low-emission production lines in steel pipe making machine factory environments.

- Asia-Pacific leads in MS pipe making machine manufacturers and steel pipe making machine price competitiveness.

What is an ERW Pipe Mill? Technology Overview & Key Parameters

The ERW pipe mill (Electric Resistance Welded Pipe Mill) is a highly automated manufacturing system for producing pipes and tubes from steel coil through uncoiling, forming, high-frequency welding, sizing, cutting, and finishing. Key related systems include the hf tube mill (high-frequency induction welding), square pipe manufacturing machine, and advanced CNC pipe mill lines.

| Parameter | ERW Pipe Mill | Seamless Pipe Mill | Submerged Arc Welded (SAW) |

|---|---|---|---|

| Main Welding Method | High-Frequency (HF) electric resistance | No weld (pierced billet) | Submerged arc welding with flux |

| Pipe Size Range (mm) | Φ12–630 | Φ21–650 | Φ406–2540 |

| Wall Thickness (mm) | 1.2–18 | 2.5–80 | 6–50 |

| Production Speed | Up to 120m/min | 3–8m/min | 1–8m/min |

| Energy Efficiency | High | Moderate | Low |

| ISO/API Compliance | Yes | Yes | Yes |

| Best Use Cases | Water/Gas, Construction, Structural | High pressure, Oil/Gas | Large-diameter, Oil Pipelines |

| Cost per Tonne (USD) | 740–1,200 | 1,200–2,700 | 1,700–2,900 |

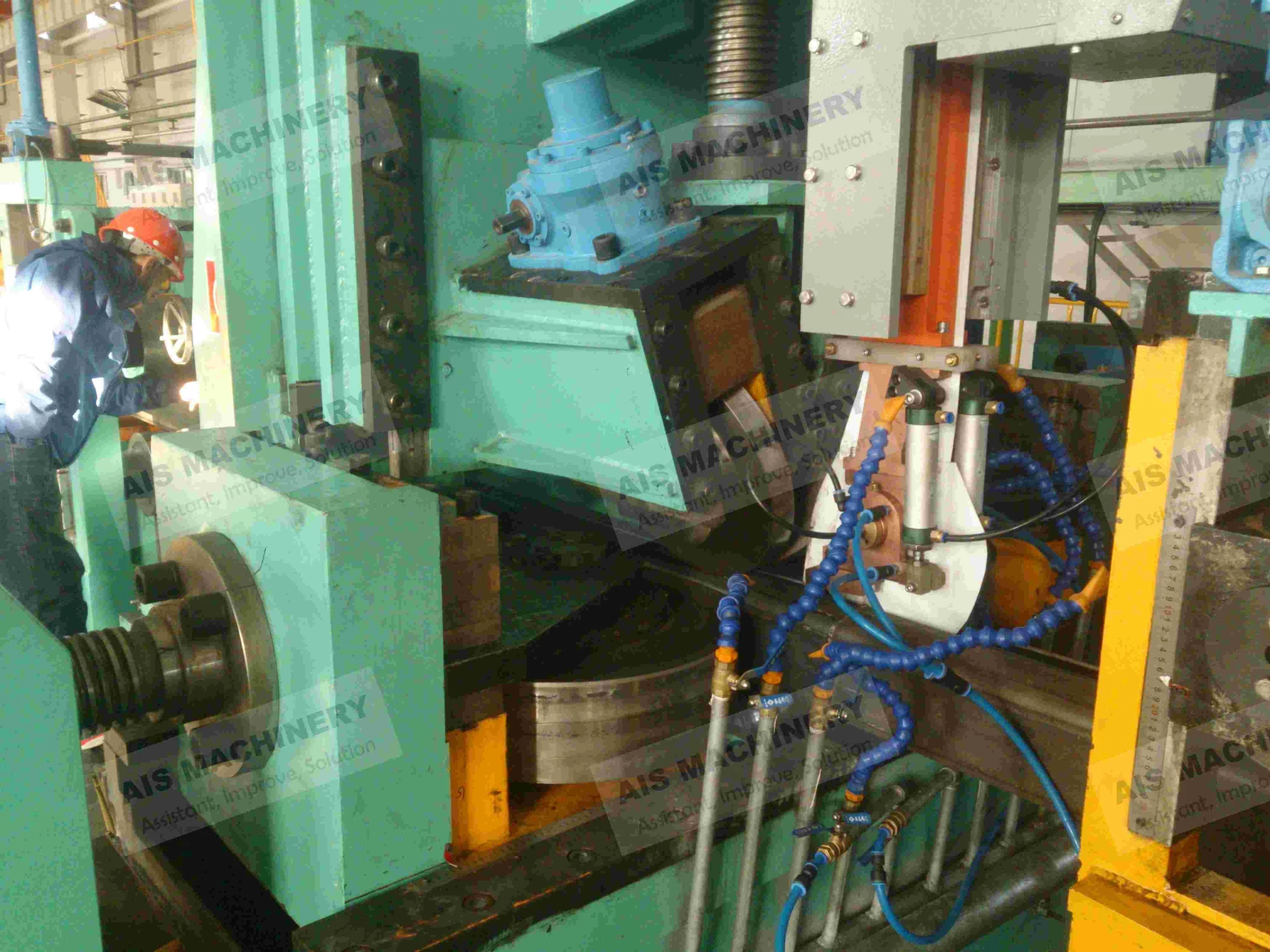

14inch 355mm ERW Tube Mill: Product Profile & Technical Insights

Product Name: 14inch 355mm ERW Tube Mill

Applicable Standards: ISO 9001, API 5L, ANSI, ASTM A53 / A500

Materials Supported: Carbon steel, mild steel, stainless steel

Pipe OD: 88.9–355.6mm (3.5–14 inch)

Wall Thickness: 2.5–12mm

Line Speed: up to 40m/min

Max. Coil Weight: 25 tons

Dimension Accuracy: ±0.03mm

Welding Technology: High-frequency (solid state / induction)

Control System: PLC+HMI, full closed-loop automation

Lifetime: 20+ years (with proper maintenance)

Industries Served: Oil & Gas, Petrochemical, Construction, Water Supply, Structural Use

Certifications: CE, ISO 9001:2015, SGS, API 5L Monogram

Manufacturing Process of ERW Pipe Mill: Step-by-Step Procedure

Key Stages Explained

- Forming: Sheets/strips cold-rolled by precision rolls into a tubular shape.

- Welding: Edges are rapidly heated using high-frequency current and joined by controlled pressure; produces strong, burr-free seams meeting API 5L X70 grades.

- NDT Inspection: Ultrasonic and radiographic testing ensures weld quality as per ISO standards.

- Sizing/Roundness: Pipe is passed through sizing stations for strict diameter tolerance—critical for square pipe making machine accuracy.

- Finishing: Pipes are cut to precise lengths, ends faced, hydro-tested for leakage, and marked for traceability.

- Material Input: Uses low-alloy, high-tensile carbon steel, stainless steel, and MS grade strips certified to ASTM A36, JIS G3452, DIN 2391.

- Precision Machining: Employs CNC-milled, induction-hardened forming and sizing rollers for rigid tolerance and minimal surface roughness (Ra < 0.6μm).

- Welding Quality: High frequency (up to 500kHz) minimizes HAZ (heat affected zone) and maximizes weld integrity for pipe mill line longevity.

- Corrosion Resistance: Custom line options include epoxy/polymer coating units—ideal for high-humidity, marine, or underground applications.

- Automation: Modern erw pipe making machine integrates automatic digital controls (PLC/SCADA), ensuring high repeatability and quick changeover for different specs.

- Testing Standards: 100% NDT (UT/ET), hydrostatic test up to 50Mpa, and dimensional monitoring by laser micrometers.

- Certifications: All major steel pipe making machine manufacturer follow ISO 9001:2015, API, and ANSI protocols for global export.

Technical Data Visualization & Product Comparison

ERW Pipe Mill Industry Competitive Analysis

| Brand/Factory | Location | Product Range | Warranty | Sample Price (USD) | Certifications |

|---|---|---|---|---|---|

| AIS Tube Mill | China | ERW/SS/MS/Square, Φ12–355/406mm | 24 mo. | 420,000 | CE, ISO, API |

| MMK Machinery | India | ERW Pipe, square pipe | 18 mo. | 390,000 | ISO, BIS |

| Formtek | USA | Piping/MF lines, API pipe, cut-to-length | 18 mo. | 550,000 | UL, ANSI |

| ZTZ | China | Carbon steel, stainless ERW tube mills | 12 mo. | 445,000 | ISO, SGS |

Tailored Solutions and Custom Pipe Mill Design

- Customization: AIS offers full customization on steel pipe making machine price, line length, specialty roll sets (for square, round, and oval shapes), and integration with existing factory ecosystems.

- Remote Diagnostics: Cloud-based PLC diagnostics and support, with predictive maintenance modules for minimum downtime.

- Turnkey Projects: From project survey, civil engineering advice, to complete pipe mill line installation and full operator training.

- After-sales Support: 24/7 expert hotline, 2–5 year warranty options, international spare parts logistics.

Real-world Application Scenarios and Case Studies

- Middle East – Oil & Gas: AIS’s erw pipe mill installed at a UAE steel works delivers API 5L X60 pipes used for 1200km oil transmission, with 99.7% weld acceptance (SGS certification).

- Vietnam – Construction: Steel pipe making machine manufacturer deployed several square pipe manufacturing machine units to supply 150,000 tons of rectangular tubes for high-rise scaffolding (project: Landmark 81).

- Europe – Water Infrastructure: Custom ms pipe making machine line produces spiral and straight-seam pipes (DN100–DN355), reducing leakage by 15% in municipal upgrades.

- Russia – Petrochemicals: HF tube mill system implemented at Tyumen tubing facility achieved 30% energy savings with its upgraded solid-state welding converter (SGQ environmental audit).

- South America – Agricultural Irrigation: Square and round carbon steel tubes enable cost-effective, corrosion-resistant distribution spanning 22,000 hectares in Brazil.

Professional FAQ: ERW Pipe Mill, Materials & Standards

- Proven Expertise: Over 20-year track record in erw pipe mill technology.

- Authoritative Certifications: All lines are ISO 9001, CE, API-certified, and pass independent audits (SGS, TÜV).

- Global References: Machines in 40+ countries, with repeat business from Fortune 500 clientele (PetroChina, Hyundai Steel, ENKA Construction).

- Innovation: 22 patented systems in high-speed pipe manufacturing machines and PLC integration.

- Trust & Compliance: Regulatory-compliant export, 100% traceability, and transparent third-party testing.

"Our new 14inch 355mm ERW Tube Mill halved setup times and improved weld quality—a game changer for our plant!"

— Chief Engineer, Southeast Asia Pipe Group

“Excellent after-sales service and rapid parts supply. The square pipe section’s accuracy exceeded our old machines by 320%.”

— Technical Director, EU Tube Works

Conclusion & Further Reading

Pervious

Pervious

This is the first article

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!