The diameter of 6 inches 168mm is already a medium-sized pipe in the straight seam welded pipe. This kind of pipe has many usage, such as solar brackets piles, ground piles, construction, etc.

This equipment can produce pipes from the smallest 2 inches 50.8mm to the largest 6 inches 168mm. A set of equipment includes all pipes. Different pipe diameters require different molds.

Customers can choose from a variety of technical styles for this set of equipment, including conventional round to square, direct square for square and rectangular pipes, or FFX flexible molding technology. No matter which option you choose, we can provide a perfect solution.

|

Опрема

|

Количина

|

Забелешка

|

|

Влезен дел

▪Пролизгање на серпентина

▪Автомобил со калем

▪Отклопувач, отварач на калеми со ролна за задржување

▪ Ролна за штипкање со уред за центрирање (Седум ролни израмнувач)

▪ Automatic Shear & welder

▪Акумулатор со хоризонтална лента

|

2 Бр.

1 бр.

1 бр.

1 бр.

1 бр.

1 бр.

|

Добавувачот

|

|

Mill section

▪Forming mill

|

1 комплет

|

Добавувачот

|

|

Welding section

▪Стандард за ролна водилка за шевови, држач за ролна стискање

▪Solid state H.F. induction welder GGp500KW

▪Надворешен уред за стругање на мониста

▪Water Cooling trough

|

1 бр.

1 бр.

1 бр.

1 бр.

|

Добавувачот

|

|

Дел за големина

▪Димензионирање ролна држач

▪Turk’s head stand

|

1 Сет.

1 Сет

|

Добавувачот

|

|

Exit section

▪Cutoff saw

▪Таса со ролери со погон ,Таса за проверка и колектори

|

1 Сет.

1 бр.

|

Добавувачот

|

|

Finishing section

▪Машина за стригтенер

▪Чамфер машина со една глава

▪Хидро тестер машина со една глава

▪Автоматска машина за пакување

|

1 Сет.

1 Сет

1 Сет

1 Сет

|

онлајн

|

2. BASIC DESIGN DATA

Дизајнот на предложената линија се заснова на следната спецификација:

Спецификација на суровина

|

Raw Material Feeding

|

CR bright tube with oiled, Galvanized steel, HR coil

|

|

Material Tensile Strength

|

Max 517MPa (75,000 psi max)

|

|

Material Yield Strength

|

Max 460MPa (67,000 psi max)

|

|

Калем ОД

|

1200mm to 2000mm

|

|

ИД на калем

|

508mm&610mm (customer order)

|

|

Тежина на серпентина

|

Max 7000 kg

|

|

Ширина на лента

|

Min 240mm, Max520mm

|

|

Дебелина на лента

|

Min2.0mm Max6.35mm

|

Опсег на производство

|

Вид на производство

|

▪Round Tubes

▪Квадратни и правоаголни шупливи пресеци

|

|

Round Tube OD

|

Min 76mm, Max 165mm

|

|

Round Tube Thickness

|

Min 2.0mm, Max 6.35mm

|

|

Квадратен шуплив дел

|

Min 60x60mm, Max 130x130mm

|

|

Правоаголен шуплив дел

|

Min 80x40mm, Max 100X160mm

|

|

Square and rectangle Tube Thickness

|

Min2.0mm, Max 5.0mm

|

|

Должина на сечењето на цевката

|

Min 6 meter, Max 12 meter

|

Line Specification

|

Line speed

|

Max 50m/min

Min 10m/min

|

|

Direction of Operation

(To be confirmed by buyer)

|

Left → Right

or

Right → Left

|

|

Welding Method

|

High Frequency Induction Welding

|

|

Total Electric installed capacity

|

1400kw

|

|

Line area

|

Approx. 70x8.0 meter (length x width)

|

Forming Section

|

Shaft material:

|

40Cr, HF tempering quenching

|

|

Material of bevel gear:

|

20CrMnTi

|

|

Driven stand

|

7 sets

|

|

Idle stand

|

8 sets

|

|

Менувачка кутија

|

7 sets

|

Sizing Section

|

Shaft material:

|

40Cr,HF tempering quenching

|

|

Material of bevel gear:

|

20CrMnTi

|

|

Driven stand

|

5 sets

|

|

Idle stand

|

5 sets

|

|

Менувачка кутија

|

5 sets

|

The Flow of the Production Line

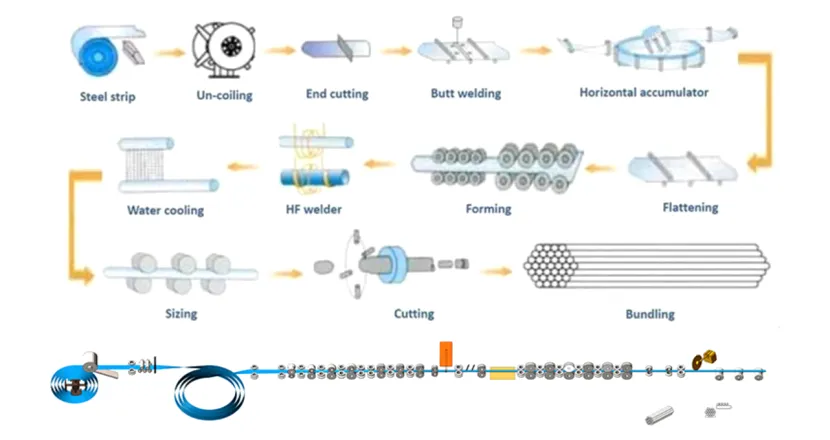

{Steel Tape}→Coil car→ Uncoiler →Peeler and hold down roll→Flattener→ Strip-head Cutter and welder→Spiral accumulator→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Cutoff saw →→ Run-out table →→Straingtener machine →→Chamfer machine →→Hydro tester machine →→automatic package machine

Common Issues and Solutions for 168mm Straight Seam Welded Pipe Equipment

Issue 1: Weak Weld Seam or Insufficient Strength

-

Possible Causes:

-

Unstable power output or improper frequency matching of the HF welder

-

Misalignment or improper seam formation

-

Worn or misaligned magnetic rod, resulting in poor induction

-

Solutions:

-

Check the HF welder output; ensure the power matches pipe size

-

Adjust roll pressure and alignment for proper seam fit

-

Replace or reposition the magnetic rod

Issue 2: Surface Scratches or Dents on the Pipe

-

Possible Causes:

-

Solutions:

Issue 3: Ovality or Inconsistent Pipe Dimensions

-

Possible Causes:

-

Solutions:

Issue 4: Uneven or Off-Center Cut by Flying Saw

-

Possible Causes:

-

Solutions:

Operational Guidelines

-

Ensure steel strip is cleaned and edges are trimmed before feeding to prevent scratches and poor seam formation.

-

Preheat the HF welder and check the cooling water system before operation to maintain proper temperature and flow.

-

Routinely inspect and adjust the magnetic rod to maintain welding efficiency and avoid weak welds.

-

Strictly follow the mold replacement and lubrication schedule to maintain equipment performance and extend service life.

-

Always conduct a dry run of the flying saw before production to confirm tracking accuracy and system response.

-

Perform daily pre-production checks (electrical system, cooling, hydraulic, drive chains, etc.) to identify hidden risks.

-

Record product dimensions and appearance daily to support equipment calibration and parameter optimization.

Тел:86-15176910262

Тел:86-15176910262