製品

ERW チューブミル、スリッティングライン、長さカットラインサプライヤー

私たちは誰ですか は ?

私たちは誰ですか?

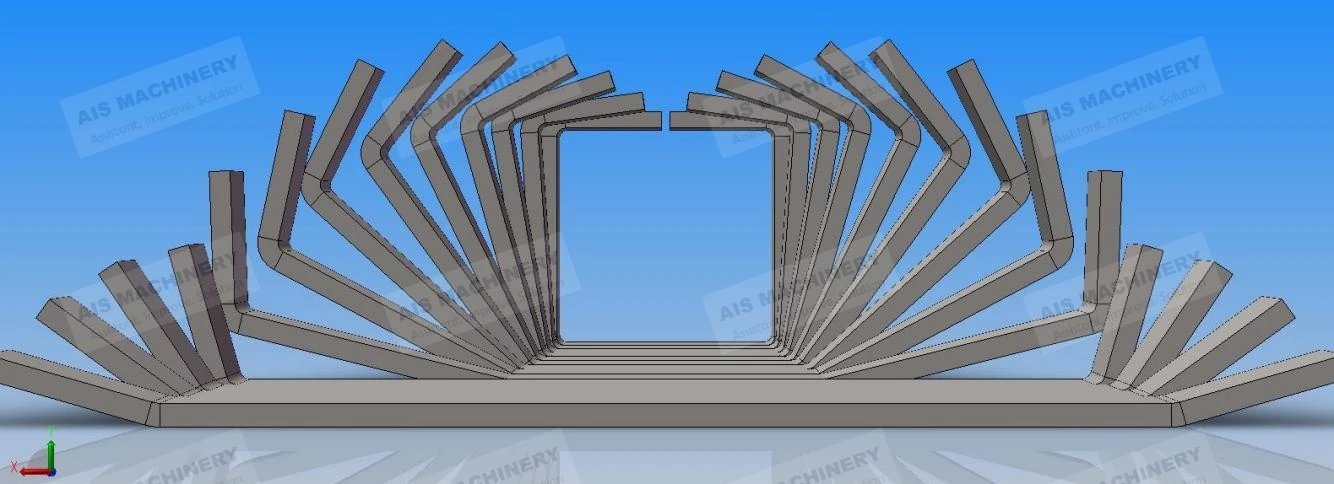

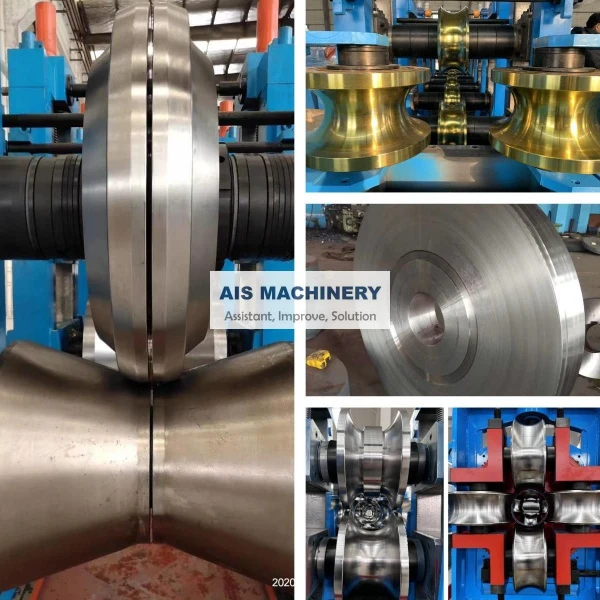

中国河北省石家荘市に位置する河北AIS機械設備CN.FactoryはISO、CE、SGSの認証を取得しており、ERWチューブミルマシン、高周波縦溶接パイプ製造機、APIパイプミル、FFX誘導溶接パイプ製造機、DFT直接角パイプミル、冷間ロール成形機、多機能チューブミルマシン、スチールコイルスリッターライン、長さカットライン、その他のスペアパーツの専門サプライヤーです。

現在、AIS Machinery はカスタマイズされた信頼性の高い製品とサービスを提供することに尽力しています。プロのエンジニアと経験豊富な技術者のグループが、信頼性の高い製品とサービスで現在の市場の需要に対応します。工場ではエンジニアリング設計、信頼性の高いコンポーネント、品質検査を厳格に管理し、高品質の仕上げ装置を確保しています。また、ターンキー プロジェクトの経験もあります。AIS Machinery は、装置と完全なソリューションを提供することで、100 社を超える企業にサービスを提供しています。

AISについて

場合 記録

生産 アドバンテージ

メッセージを送信

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!