1. Basic Principle

-

Electromagnetic Induction:

The eddy current flaw detector uses a probe coil energized with high-frequency alternating current (AC), which generates an alternating magnetic field.

-

Eddy Current Generation:

When a conductive material (e.g., a welded steel pipe) passes through the coil, the changing magnetic field induces circulating electrical currents on the material’s surface—these are called eddy currents.

-

Defect Disturbance:

In defect-free material, eddy currents flow uniformly. If cracks, pores, inclusions, or lack of fusion exist, they disturb the electrical or magnetic properties, altering the eddy current distribution.

-

Signal Detection & Analysis:

These disturbances affect the coil's impedance (voltage, current, phase), which is amplified, filtered, and analyzed by the system’s electronics. The result appears as signals on a display for interpretation.

2. Functions and Applications

-

Weld Seam Inspection: Detects defects such as cracks, lack of fusion, porosity, and inclusions.

-

品質管理: Ensures product quality and reduces scrap rate.

-

Automatic Sorting: Can be linked with rejection systems to automatically remove defective pipes.

-

High-Speed Detection: Suitable for high-speed production lines.

-

Non-Contact Detection: No physical contact with the pipe, reducing wear and tear.

3. Basic Specifications (Typical)

| Item |

Specification |

| Pipe Diameter Range |

Ø5 mm – Ø120 mm |

| Testing Speed |

Up to 120 m/min |

| Operating Frequency |

100 kHz – 1 MHz (adjustable) |

| Sensitivity |

Detects cracks smaller than Ø0.2 mm |

| Output Interfaces |

Alarm relay / RS485 / Ethernet |

| Probe Types |

Encircling coil, pancake coil, etc. |

| Display & Control |

Industrial touchscreen or PC software |

4. Main Components

-

High-Frequency Power Supply: Generates excitation current for the probe.

-

Eddy Current Probe (Coil): Induces and detects eddy current changes.

-

Signal Amplifier & Processor: Amplifies and filters detection signals.

-

Alarm Unit: Provides audio/visual alerts for defects.

-

Display and Control Panel: Interface for monitoring and parameter adjustment.

-

Mechanical Fixture: Holds and positions the probe relative to the pipe.

-

5.Application in Welded Pipe Equipment

-

Post-Weld Inspection:

The eddy current tester is installed after the welding stage but before sizing, to inspect weld seams in real time.

-

Continuous Online Testing:

As the pipe moves through an encircling coil probe, the device continuously scans the weld area for flaws.

-

Real-Time Alarm and Rejection:

When a defect is detected, the system triggers an alarm and can activate an automated rejection mechanism to remove the defective pipe.

6. Operating Procedure

-

Installation & Calibration

-

Parameter Setup

-

Set frequency, gain, and filters according to pipe size and material.

-

Calibrate using standard defect samples.

-

Start Testing

-

Defect Alarm & Handling

-

If a flaw is detected, the system triggers an alarm.

-

Defective pipes are automatically rejected via a mechanical system.

-

Data Recording & Analysis

7. Factors Affecting Test Performance

-

Operating Frequency:

High frequencies detect surface flaws; lower frequencies penetrate deeper.

-

Material Type:

Different conductivity and magnetic permeability affect eddy current response.

-

Probe Design:

Must match pipe diameter and weld location.

-

Speed & Stability:

High-speed operation requires stable signal acquisition and precise mechanical setup.

🔁 Summary

The core principle of eddy current testing is:

“Defects disturb eddy currents → Eddy currents alter coil impedance → Electrical signal changes are detected and analyzed.”

It is a non-contact, high-speed, and highly sensitive method ideal for inline weld inspection in pipe manufacturing.

-

-

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. 渦電流検査装置

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

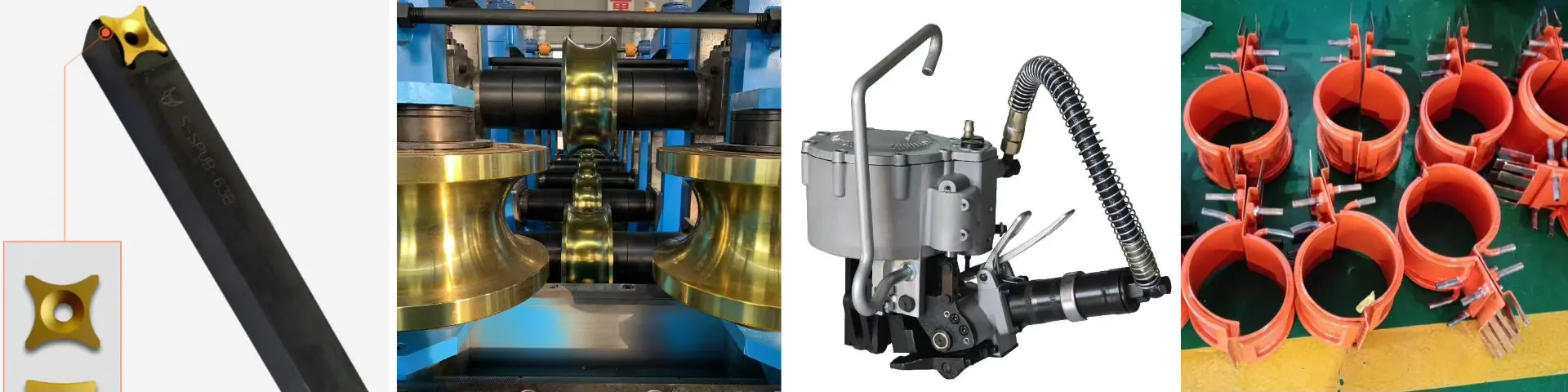

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

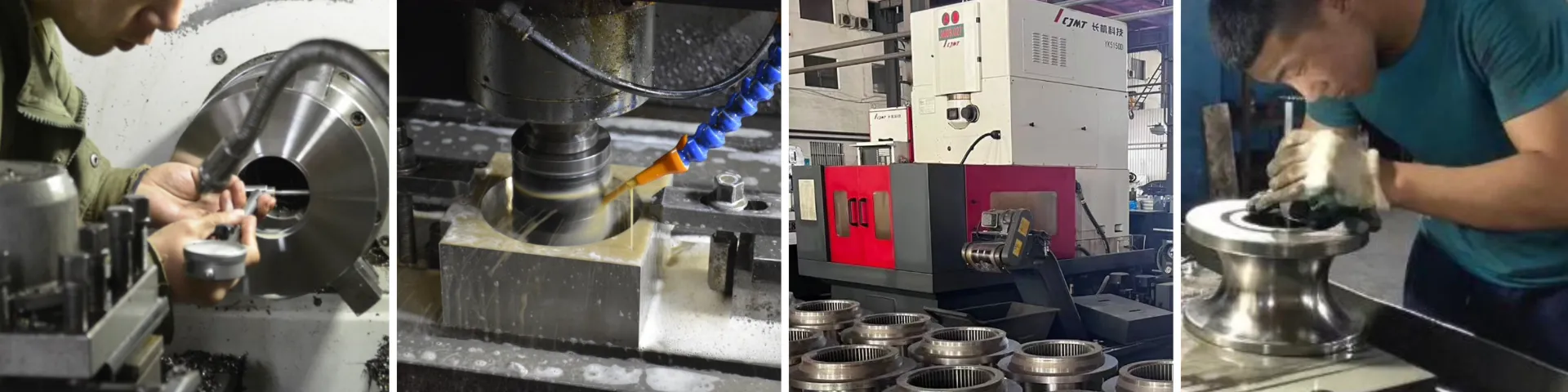

- 当社を選ぶ理由

-

1.Leading Technology, Reliable Quality, Excellent Service! 最適化されたデザイン、高品質の素材を選択! 熱処理工程保証!

-

2.Spiral bevel gear, drum gear coupling and carburization. ギア歯の焼入れ。 駆動システムは安定性、効率性、装着性、低ノイズを実現。

-

3.High precision wear resisting and Long life of toolings. すべての機械旋盤、キー溝は CNC によって位置決めおよびフライス加工されます。

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

アフターサービス

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- エンジニアの対応には5~24時間かかります。

- 6. お客様と当社とのビジネス関係はいかなる第三者に対しても秘密にされます。

- 7. We welcome customers to visit our factory anytime.