1. Basic Principle

-

Electromagnetic Induction:

The eddy current flaw detector uses a probe coil energized with high-frequency alternating current (AC), which generates an alternating magnetic field.

-

Eddy Current Generation:

When a conductive material (e.g., a welded steel pipe) passes through the coil, the changing magnetic field induces circulating electrical currents on the material’s surface—these are called eddy currents.

-

Defect Disturbance:

In defect-free material, eddy currents flow uniformly. If cracks, pores, inclusions, or lack of fusion exist, they disturb the electrical or magnetic properties, altering the eddy current distribution.

-

Signal Detection & Analysis:

These disturbances affect the coil's impedance (voltage, current, phase), which is amplified, filtered, and analyzed by the system’s electronics. The result appears as signals on a display for interpretation.

2. Functions and Applications

-

Weld Seam Inspection: Detects defects such as cracks, lack of fusion, porosity, and inclusions.

-

Контроль якості: Ensures product quality and reduces scrap rate.

-

Automatic Sorting: Can be linked with rejection systems to automatically remove defective pipes.

-

High-Speed Detection: Suitable for high-speed production lines.

-

Non-Contact Detection: No physical contact with the pipe, reducing wear and tear.

3. Basic Specifications (Typical)

| Item |

Specification |

| Pipe Diameter Range |

Ø5 mm – Ø120 mm |

| Testing Speed |

Up to 120 m/min |

| Operating Frequency |

100 kHz – 1 MHz (adjustable) |

| Sensitivity |

Detects cracks smaller than Ø0.2 mm |

| Output Interfaces |

Alarm relay / RS485 / Ethernet |

| Probe Types |

Encircling coil, pancake coil, etc. |

| Display & Control |

Industrial touchscreen or PC software |

4. Main Components

-

High-Frequency Power Supply: Generates excitation current for the probe.

-

Eddy Current Probe (Coil): Induces and detects eddy current changes.

-

Signal Amplifier & Processor: Amplifies and filters detection signals.

-

Alarm Unit: Provides audio/visual alerts for defects.

-

Display and Control Panel: Interface for monitoring and parameter adjustment.

-

Mechanical Fixture: Holds and positions the probe relative to the pipe.

-

5.Application in Welded Pipe Equipment

-

Post-Weld Inspection:

The eddy current tester is installed after the welding stage but before sizing, to inspect weld seams in real time.

-

Continuous Online Testing:

As the pipe moves through an encircling coil probe, the device continuously scans the weld area for flaws.

-

Real-Time Alarm and Rejection:

When a defect is detected, the system triggers an alarm and can activate an automated rejection mechanism to remove the defective pipe.

6. Operating Procedure

-

Installation & Calibration

-

Parameter Setup

-

Set frequency, gain, and filters according to pipe size and material.

-

Calibrate using standard defect samples.

-

Start Testing

-

Defect Alarm & Handling

-

If a flaw is detected, the system triggers an alarm.

-

Defective pipes are automatically rejected via a mechanical system.

-

Data Recording & Analysis

7. Factors Affecting Test Performance

-

Operating Frequency:

High frequencies detect surface flaws; lower frequencies penetrate deeper.

-

Material Type:

Different conductivity and magnetic permeability affect eddy current response.

-

Probe Design:

Must match pipe diameter and weld location.

-

Speed & Stability:

High-speed operation requires stable signal acquisition and precise mechanical setup.

🔁 Summary

The core principle of eddy current testing is:

“Defects disturb eddy currents → Eddy currents alter coil impedance → Electrical signal changes are detected and analyzed.”

It is a non-contact, high-speed, and highly sensitive method ideal for inline weld inspection in pipe manufacturing.

-

-

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Вихрострумова машина

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

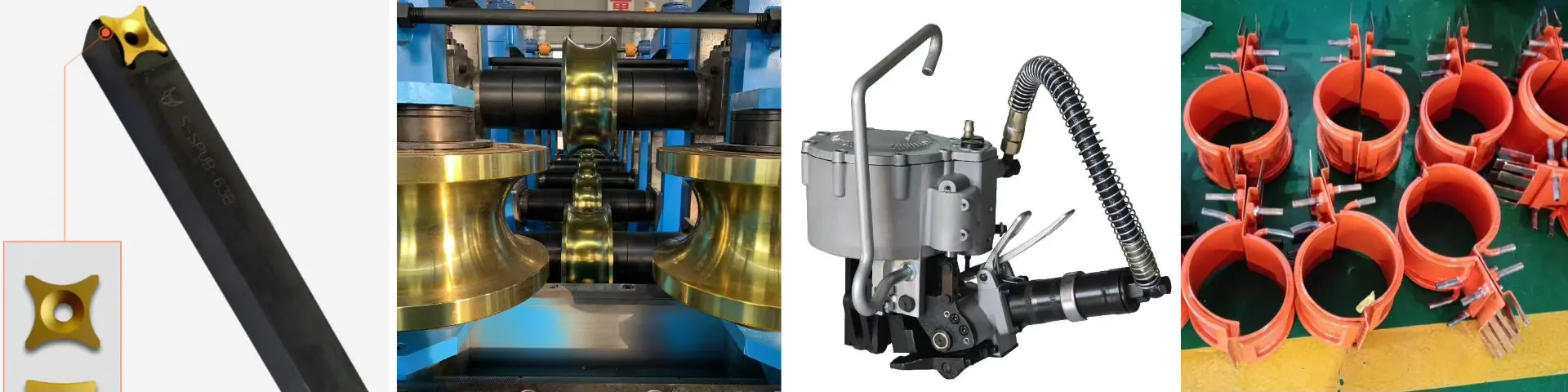

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Чому обирають нас?

-

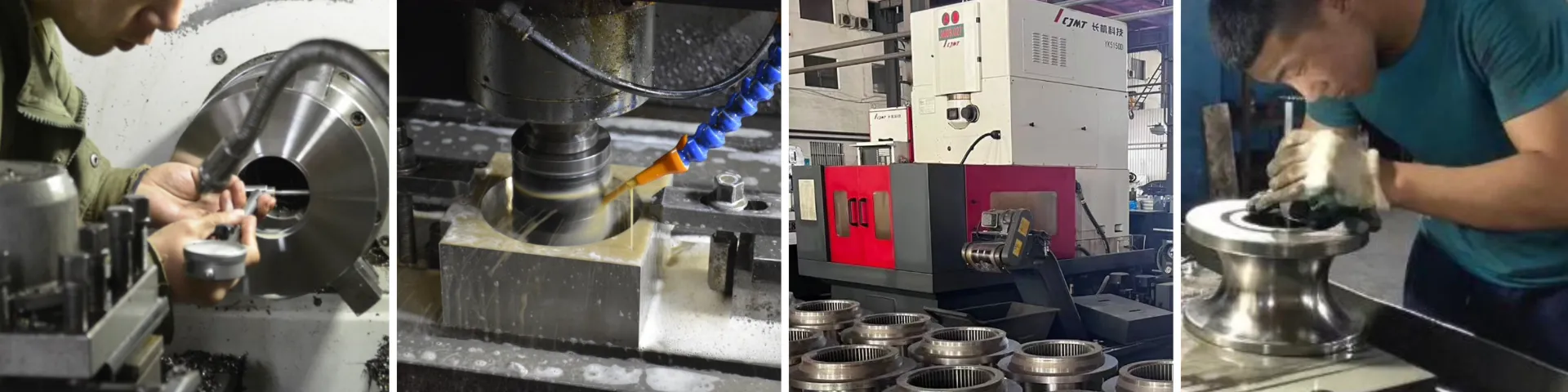

1.Leading Technology, Reliable Quality, Excellent Service! Оптимізований дизайн, вибір високоякісних матеріалів! Гарантія процесу термічної обробки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Загартування зубів шестерень. Привідна система стабільна, ефективна та придатна до носіння з низьким рівнем шуму.

-

3.High precision wear resisting and Long life of toolings. Усі токарні верстати, шпонкові канавки позиціонуються та фрезеруються за допомогою ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Післяпродажне обслуговування

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5.24 години для відповіді інженера.

- 6. Ваші ділові відносини з нами будуть конфіденційними для будь-якої третьої сторони.

- 7. We welcome customers to visit our factory anytime.

Тел.: 86-15176910262

Тел.: 86-15176910262