生産範囲

|

生産タイプ

|

▪正方形および長方形の中空セクション

|

|

角中空断面

|

Min 60x60mm, Max 130x130mm

|

|

長方形中空断面

|

Min 80x40mm, Max 100X160mm

|

|

Square and rectangle Tube Thickness

|

Min2.0mm, Max 5.0mm

|

|

チューブカット長さ

|

Min 6 meter, Max 12 meter

|

Line Specification

1. Technical Overview

Direct square forming (also known as direct forming to square or rectangular tube) is a tube mill process in which flat steel strip is directly formed into square or rectangular shapes without first forming into a round pipe. The entire shaping takes place in the form-and-size section, enabling a more efficient, accurate, and material-saving production for hollow structural sections (HSS).

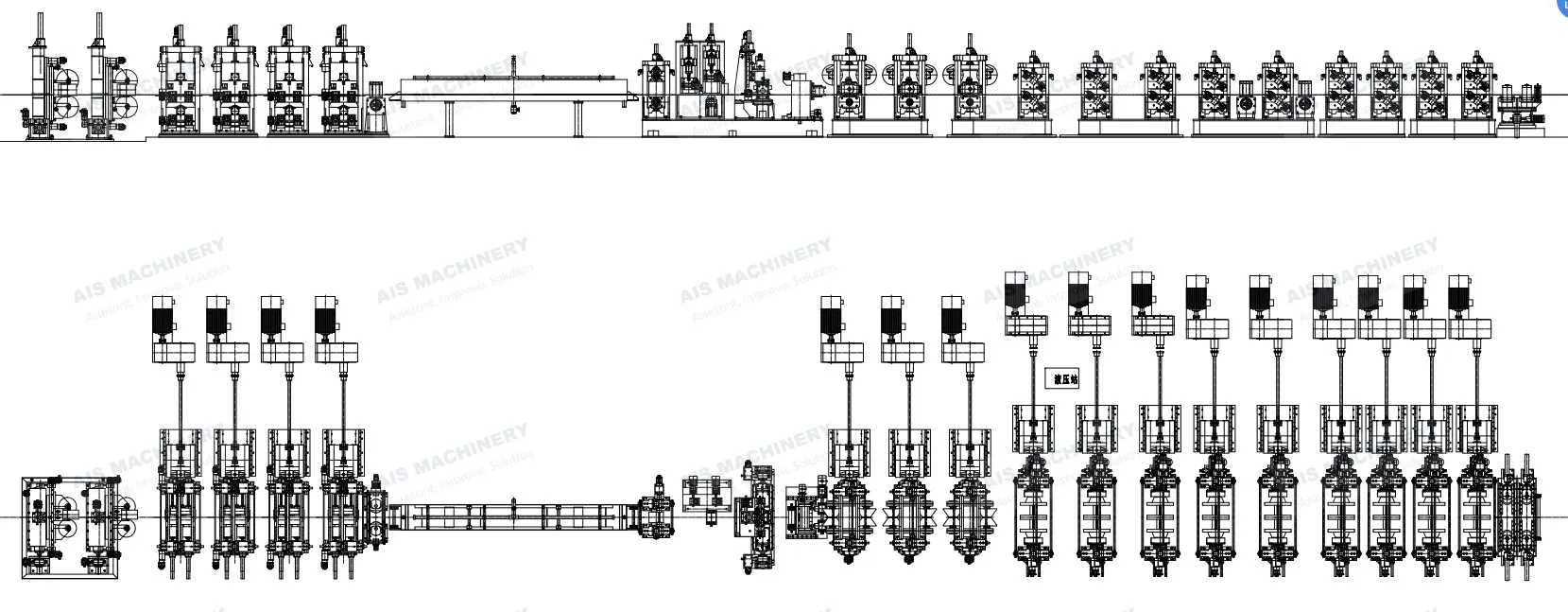

2. Process Flow

Coil → Uncoiler → Leveling → Shearing & Welding → Accumulator → Forming Section (Direct Square) → HF Welding → Burr Removal → Cooling → Sizing Section → Flying Saw → Stacking

🔧 Detailed Steps:

-

Material Entry: Steel strip is leveled and joined via shear & welder.

-

Forming Section: Gradual deformation of flat strip into square/rectangular shape through roll forming – no round stage involved.

-

High-Frequency Welding: Weld seam generated along one edge (typically inner corner).

-

Weld Bead Removal: Internal and/or external trimming as required.

-

Cooling System: Water spray cooling to stabilize tube shape and microstructure.

-

Sizing Section: Final shaping and dimension correction; ensures angle sharpness and wall flatness.

-

Flying Saw Cutting: Length-wise cutting according to user-set lengths.

-

Output Table / Auto Stacker: Pipe collection and automatic alignment.

3. Technical Parameters

| Item |

Specification Range |

| Applicable Tube Shape |

Square & Rectangular (Direct Formed) |

| Tube Size Range |

20×20 mm – 120×120 mm (Square) /

30×20 mm – 160×80 mm (Rectangular) |

| Wall Thickness Range |

1.2 mm – 6.0 mm |

| Line Speed |

30–80 m/min (depending on size & thickness) |

| Material Grade |

Low to high strength carbon steel (≤ Q355 / S355) |

| Forming Method |

Direct roll forming (no round forming stage) |

| Welding Method |

High-Frequency Induction Welding |

| Dimension Tolerance |

±0.5 mm (width), ±0.15 mm (wall thickness) |

| Diagonal Deviation |

≤0.8 mm for 100×100 mm tube |

Note: Larger sizes (up to 250×250 mm or more) available on request using modular mill setups.

4. Advantages of Direct Square Technology

✅ Efficiency & Material Saving

-

Avoids round pre-forming, reducing tooling steps and energy consumption.

-

Saves up to 2–3% material by reducing corner stretching and less reshaping.

✅ High Product Accuracy

-

Achieves precise outer dimensions, excellent flatness of sides, and sharp corners.

-

Stable weld seam location along corner (more uniform structure).

✅ Tooling Flexibility

✅ Reduced Maintenance & Wear

5. Application Scope

This technology is suitable for manufacturers focusing on:

-

Hollow Structural Sections (HSS)

-

Mechanical & Automotive Frames

-

Steel Furniture Tubes

-

Scaffold Tubes / Guard Rails

-

Solar Panel Mounting Structures

-

Greenhouse & Agricultural Frames

Especially advantageous when production is focused on square/rectangular tubes only and requires high output, repeatability, and low running cost.

6. Frequently Asked Questions (FAQ)

Q1: Is direct square forming better than round-to-square?

A: For dedicated square/rectangular tube production, yes. It eliminates redundant forming stages and provides better efficiency. However, if the mill needs to produce both round and square tubes, round-to-square offers more flexibility.

Q2: Can this process handle high-strength or galvanized steel?

A: Yes. As long as the line is equipped with proper roll material (D2, Cr12MoV, or carbide), and forming passes are adjusted accordingly, direct square forming can handle Q345/S355, galvanized coils, and even certain AHSS grades.

Q3: What are the limitations of this process?

A: It’s not ideal for very small tubes (e.g., <20×20 mm) or extremely thin walls (<1.2 mm), as the corner formability and weld control become difficult without round shaping.

Q4: How is weld seam quality ensured without round pre-forming?

A: Through precise edge positioning before welding, and using automatic seam tracking systems with real-time correction. The weld seam is located along a corner, where stress distribution is relatively favorable.

Q5: What’s the typical tooling changeover time for a new size?

A: With manual roll change: 3–5 hours.

With quick-change cassette type: 30–60 minutes.

✅ Summary

Direct square forming is a highly efficient, cost-effective solution for large-volume production of square and rectangular tubes, delivering improved yield, precision, and structural consistency — especially when integrated with automatic control systems and modular tooling design.

The Flow of the Production Line

Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener