제품

ERW 튜브 밀, 슬리팅 라인, 길이에 맞춰 절단 라인 공급업체

우리는 누구인가 이다 ?

우리는 누구인가?

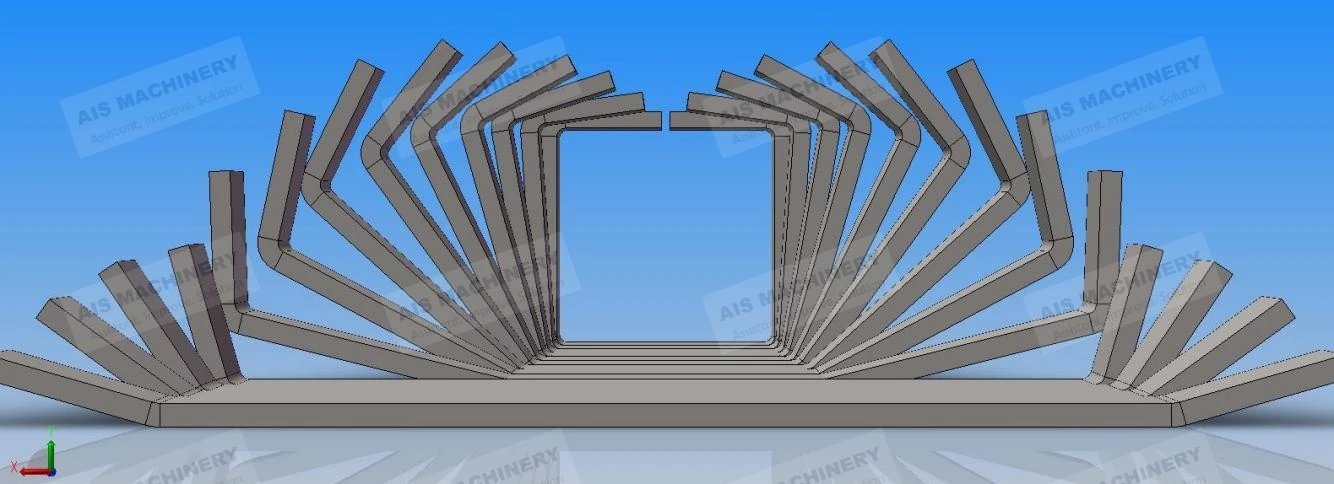

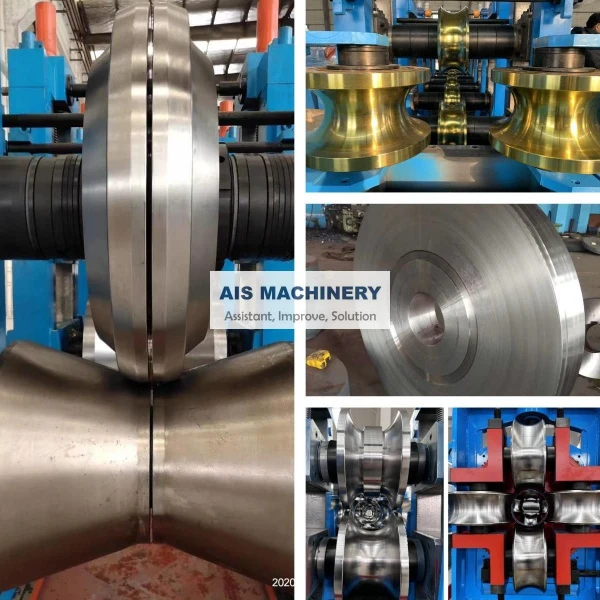

허베이 AIS 기계 장비는 중국 허베이성 스자좡시에 위치하고 있습니다. 공장은 ISO, CE 및 SGS 인증을 받았으며 ERW 튜브 밀 기계, 고주파 세로 용접 파이프 제조 기계, API 파이프 밀, FFX 유도 용접 파이프 제조 기계, DFT 직접 성형에서 사각 파이프 밀로, 콜드 롤 성형 기계, 다기능 튜브 밀 기계, 강철 코일 슬리팅 라인, 길이 절단 라인 및 기타 예비 부품을 전문적으로 공급합니다.

오늘날 AIS Machinery는 맞춤형의 신뢰할 수 있는 제품과 서비스를 제공하기 위해 최선을 다하고 있습니다. 신뢰할 수 있는 제품과 서비스로 현재 시장 수요를 충족시키는 전문 엔지니어와 숙련된 기술자 그룹이 있습니다. 엔지니어링 설계, 신뢰할 수 있는 구성 요소 및 품질 검사를 엄격하게 통제하는 공장은 고품질 마무리 장비를 보장합니다. 또한 턴키 프로젝트에 대한 경험이 있습니다. AIS Machinery는 장비와 완벽한 솔루션을 제공하여 100개 이상의 기업에 서비스를 제공합니다.

AIS 소개

사례 기록

생산 이점

메시지 보내기

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!