예비 부품

예비 부품은 기계, 장치 또는 시스템의 손상되거나 마모된 부품을 교체하는 데 사용되는 구성 요소 또는 액세서리입니다. 예비 부품은 장비의 기능과 효율성을 유지하고, 가동 중지 시간을 최소화하며, 기계의 수명을 연장하는 데 중요합니다. 자동차, 제조, 전자 및 산업 기계를 포함한 다양한 산업에서 널리 사용됩니다. 예비 부품은 볼트, 기어 및 필터와 같은 간단한 구성 요소에서 모터, 회로 기판 또는 유압 시스템과 같은 보다 복잡한 부품까지 다양합니다. 예비 부품의 주요 기능은 장비 고장에 대한 빠르고 효율적인 솔루션을 제공하여 전체 시스템을 교체할 필요성을 줄이는 것입니다. 예비 부품은 종종 원래 부품과 동일하거나 호환되도록 설계되어 기존 시스템에 원활하게 통합됩니다.

자동차와 같은 산업에서 예비 부품은 차량 유지 관리 및 수리에 필수적입니다. 제조 및 산업 환경에서 예비 부품은 생산 라인을 가동 상태로 유지하고 비용이 많이 드는 지연 및 중단을 방지하는 데 필수적입니다. 전자 제품의 경우 배터리, 화면 또는 회로 기판과 같은 예비 부품은 장치가 시간이 지나도 작동 상태를 유지하도록 합니다. 예비 부품의 가용성과 품질은 원활한 작동에 중요합니다. 제조업체는 종종 자사 기계에 맞게 특별히 설계된 정품 예비 부품(OEM 부품)과 더 저렴하지만 여전히 호환되는 사후 부품을 제공합니다. 예비 부품의 적절한 관리 및 적시 교체는 장비의 전반적인 성능과 안정성을 유지하는 데 필수적입니다. 예비 부품은 기계 및 시스템의 유지 관리 및 수리에 필수적이며, 지속적인 성능을 보장하고, 가동 중단 시간을 줄이며, 다양한 산업에서 장비의 수명을 연장합니다.

Importance and Necessity of Consumables and Spare Parts in the Operation of Longitudinal Welded Pipe Equipment and Slitting Equipment

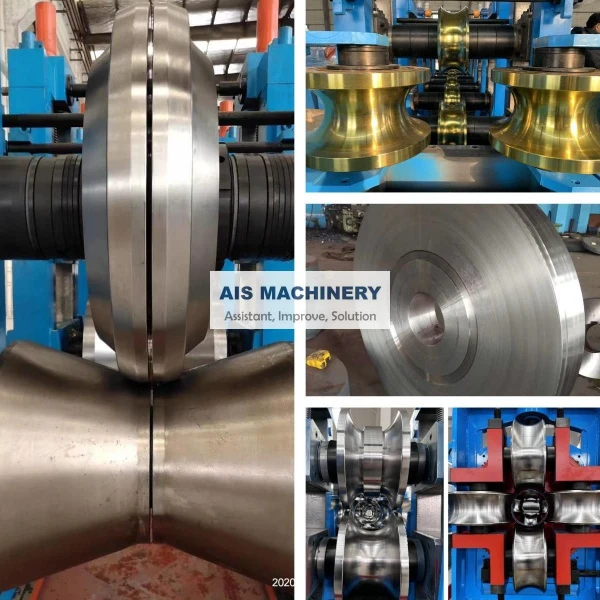

Consumables and spare parts play a crucial role in the operation of longitudinal welded pipe equipment and slitting equipment. They not only ensure the stable operation of the equipment but also directly impact production efficiency and product quality. Proper management of consumables and spare parts can effectively reduce downtime, improve overall production efficiency, and ensure that the products meet quality standards.

1. Importance of Consumables and Spare Parts

-

Ensuring Continuous Production: In a high-demand production environment, equipment inevitably experiences wear or aging. Timely replacement of consumables and spare parts helps avoid equipment failures, ensuring the smooth operation of the production line.

-

Extending Equipment Life: High-quality consumables and spare parts effectively reduce the wear of equipment components, decreasing the need for repairs and extending the service life of the equipment.

-

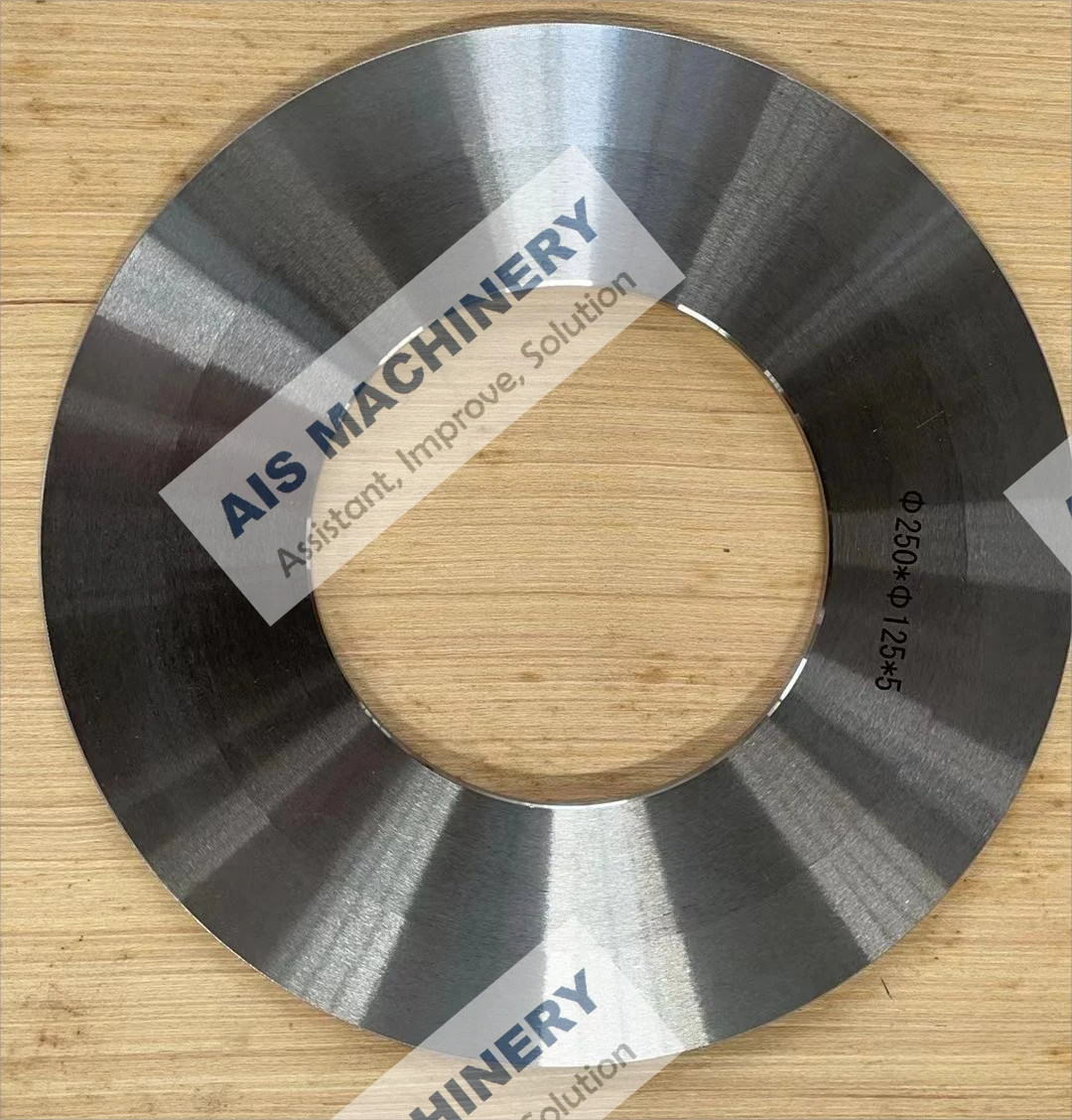

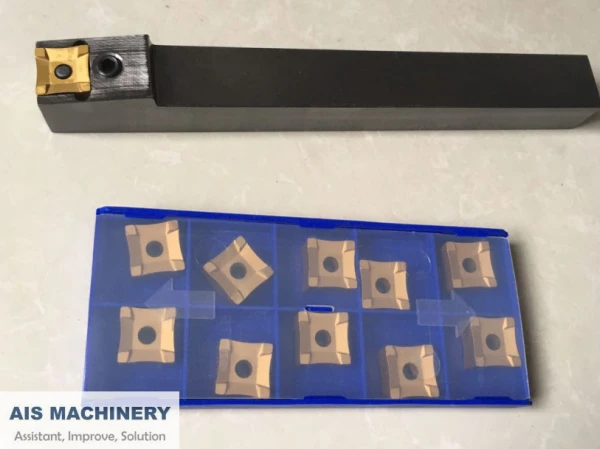

Ensuring Product Quality: Consumables such as welding materials, cutting tools, lubricants, etc., directly affect the quality of products. Choosing the right consumables ensures smooth product surfaces, good welding quality, and reduces defect rates.

-

Optimizing Equipment Performance: The selection of consumables impacts the operational efficiency of the equipment. For example, the sharpness of cutting tools directly affects cutting accuracy, and suitable welding materials affect the strength of the welds. Using the right consumables and spare parts optimizes equipment performance and boosts production efficiency.

2. Necessity of Consumables and Spare Parts

-

Preventive Maintenance: Regular inspection and replacement of consumables and spare parts are part of preventive maintenance, effectively preventing equipment breakdowns and reducing downtime.

-

Emergency Repairs: Equipment may fail unexpectedly under heavy use, and having spare parts readily available allows for quick repairs, minimizing production stoppages.

-

Reducing Production Interruptions: Shortages of consumables and spare parts can lead to equipment downtime and production interruptions, increasing production costs. Therefore, maintaining an adequate inventory ensures continuous production and helps reduce operational costs.

3. How to Select Suitable Consumables

-

Quality and Specification Compatibility: Consumables and spare parts should match the specifications and model of the equipment. Choose high-quality products that meet the equipment's design requirements to ensure long-term reliability and stability.

-

Reliable Performance: Consumables and spare parts should be selected from tested and certified brands to ensure stable and consistent performance. For example, welding materials should be chosen based on their ability to withstand high temperatures and fast operations, while cutting tools should be durable and wear-resistant.

-

Supplier Reputation: Choose reliable, reputable suppliers who provide high-quality consumables and spare parts with timely delivery. Suppliers offering comprehensive after-sales service and technical support should be prioritized.

-

Cost and Benefit Balance: When selecting consumables and spare parts, consider both cost and benefit, ensuring quality while avoiding unnecessary costs from excessive procurement.

4. How Much Inventory of Consumables is Appropriate

-

Production Demand: Inventory levels should be determined based on the scale of production, the frequency of equipment use, and the replacement cycle of consumables. Equipment used frequently requires more spare parts inventory, while less frequently used equipment may need fewer spare parts.

-

Equipment Maintenance Cycle: Inventory levels should align with the maintenance cycle of the equipment. For example, for welded pipe equipment, welding materials and consumables should be stocked based on usage frequency and the maintenance schedule.

-

Safety Stock: To deal with unexpected equipment failures or production plan changes, it is advisable to keep a certain amount of safety stock. Generally, the safety stock should be 1 to 2 times the normal production requirement to cope with unforeseen demands.

-

Supply Chain Considerations: Consider the stability of the supply chain and the delivery times of suppliers to avoid production delays caused by supply interruptions. Inventory levels can be adjusted based on the delivery cycle and past delivery records of suppliers.

Conclusion

Proper management of consumables and spare parts is key to the efficient operation of longitudinal welded pipe equipment and slitting equipment. By selecting suitable consumables and spare parts, maintaining appropriate inventory levels, and performing regular inspections and replacements, companies can effectively reduce equipment downtime, increase production efficiency, ensure product quality, and lower long-term operational costs.

메시지 보내기

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!