Fiberglass+Ferrite+copper end

Return flow of cooling liquid ( round , square and rectangular sections )

Through flow impeders are the most common type of impeders and are a relatively simple concept, our designs ensure maximum high quality ferrite mass is placed within a well-constructed assembly. The result is improved performance, saving you money and increasing productivity.

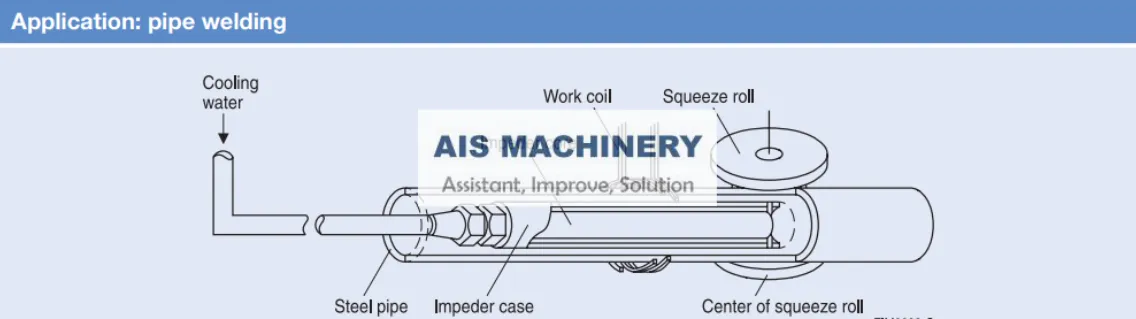

mpeders must be always well proportioned and always together with inductors since together they create the electromagnetic inductive circuits that allow a good and efficient induction welding.

The high-frequency welding impeder is a critical component within welded tube production lines, typically installed inside the pipe near the weld seam. Its primary function is to guide and concentrate the high-frequency current along the strip edges, preventing current from dispersing through the center of the tube. This intensifies both the skin and proximity effects, ensuring fast and focused heating at the weld zone.

Impeders are generally constructed using high-permeability ferrite materials or iron-core assemblies, and can be configured in various shapes and sizes to suit specific production needs. A well-designed impeder improves energy efficiency, enhances weld consistency, and stabilizes the heating process—leading to stronger, cleaner welds and higher line speeds.

In addition to improving electrical efficiency, quality impeders offer excellent thermal resistance, mechanical strength, and magnetic performance, allowing them to withstand the demanding environment of continuous high-frequency operations. Proper selection based on parameters such as pipe diameter, operating frequency, and welding power is essential for achieving optimal welding results.

All of our impeders are designed to ensure effective cooling and protection of the ferrite core inside the construction. It is essential that ferrite is properly cooled to maximise welding efficiency and maintain stable parameters for product quality.

Standard through flow impeders – Ferrite is totally enclosed inside the casing

Exposed Ferrite impeders – around 10-15% of the end of the ferrite protrudes from the casing

We have standard male imperial couplings but can offer metric or other threads on request.

Impeders are available in length options of 230mm, 330mm & 430mm.

Impeder Cooling: 당사의 모든 임피더는 임피더 내부의 페라이트 코어를 효과적으로 냉각하고 보호하도록 설계되었습니다. 용접 효율을 극대화하고 제품 품질을 위한 안정적인 매개변수를 유지하려면 페라이트를 효율적으로 냉각하는 것이 필수적입니다. 냉각수는 깨끗해야 하며, 가급적 여과해야 합니다. 압력은 대부분의 작동 조건에서 적절한 냉각을 보장합니다. 냉각수 흐름 요구 사항은 입구 온도, 용접 전력, 주파수 및 용접 영역 형상으로 인해 크게 다릅니다. 고전력 밀도 상황과 높은 주변 온도에서 임페더 및 작업 코일 냉각수용 소형 냉각기는 효율성을 크게 개선할 수 있습니다. Cooling by air or other gas is not recommended, but can be useful in special situations where the presence of water inside the tube cannot be tolerated. Gas, such as nitrogen, have a density that is at least 1,000 times less than that of water, so coolant volume must be increased accordingly.

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. 와류기

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

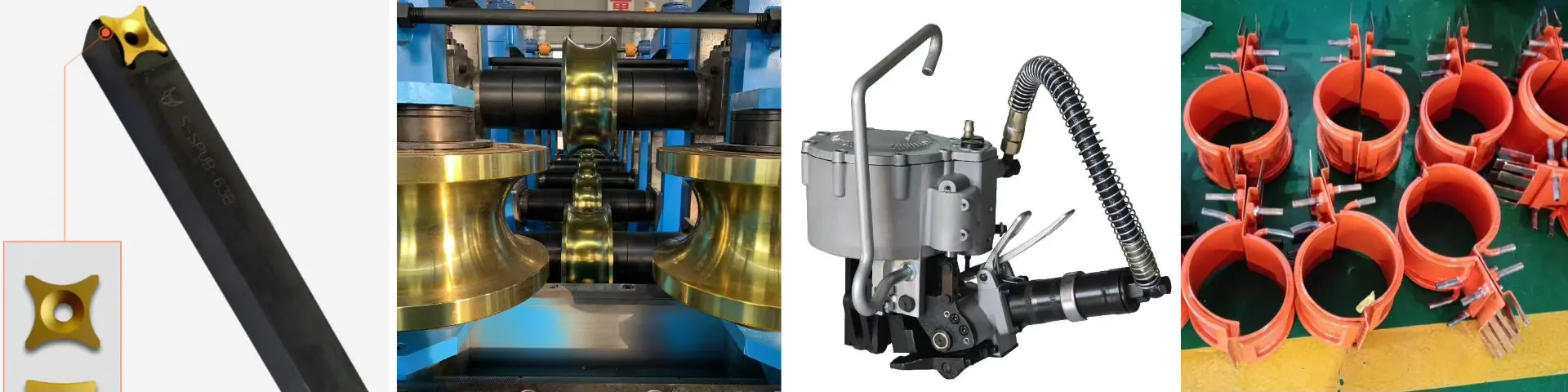

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- 왜 우리를 선택하시나요?

-

1.Leading Technology, Reliable Quality, Excellent Service! 최적화된 디자인, 고품질 소재 선택! 열처리 과정 보증!

-

2.Spiral bevel gear, drum gear coupling and carburization. 기어 이빨 담금질. 구동 시스템은 안정적이고 효율적이며 소음이 적고 내구성이 뛰어납니다.

-

3.High precision wear resisting and Long life of toolings. 모든 기계 선반과 키 홈은 CNC로 위치가 지정되고 밀링됩니다.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

애프터서비스

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 엔지니어가 응답하기까지 5.24시간이 걸립니다.

- 6. 귀사와 당사 간의 사업 관계는 모든 제3자에게 비밀로 유지됩니다.

- 7. We welcome customers to visit our factory anytime.