Fiberglass+Ferrite+copper end

Return flow of cooling liquid ( round , square and rectangular sections )

Through flow impeders are the most common type of impeders and are a relatively simple concept, our designs ensure maximum high quality ferrite mass is placed within a well-constructed assembly. The result is improved performance, saving you money and increasing productivity.

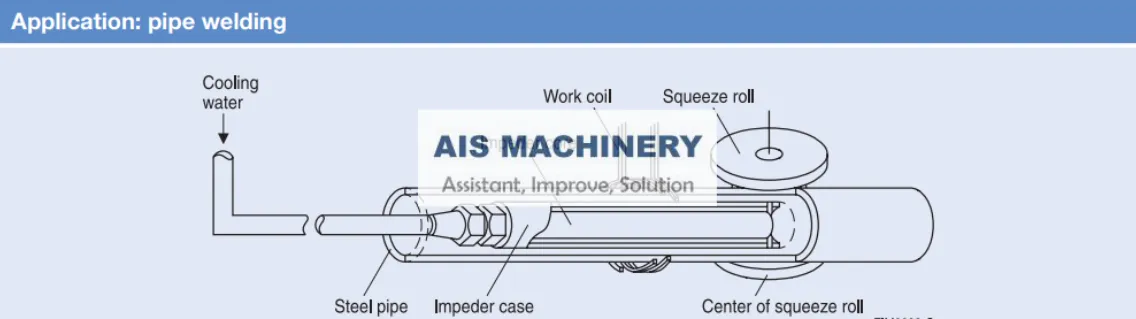

mpeders must be always well proportioned and always together with inductors since together they create the electromagnetic inductive circuits that allow a good and efficient induction welding.

The high-frequency welding impeder is a critical component within welded tube production lines, typically installed inside the pipe near the weld seam. Its primary function is to guide and concentrate the high-frequency current along the strip edges, preventing current from dispersing through the center of the tube. This intensifies both the skin and proximity effects, ensuring fast and focused heating at the weld zone.

Impeders are generally constructed using high-permeability ferrite materials or iron-core assemblies, and can be configured in various shapes and sizes to suit specific production needs. A well-designed impeder improves energy efficiency, enhances weld consistency, and stabilizes the heating process—leading to stronger, cleaner welds and higher line speeds.

In addition to improving electrical efficiency, quality impeders offer excellent thermal resistance, mechanical strength, and magnetic performance, allowing them to withstand the demanding environment of continuous high-frequency operations. Proper selection based on parameters such as pipe diameter, operating frequency, and welding power is essential for achieving optimal welding results.

All of our impeders are designed to ensure effective cooling and protection of the ferrite core inside the construction. It is essential that ferrite is properly cooled to maximise welding efficiency and maintain stable parameters for product quality.

Standard through flow impeders – Ferrite is totally enclosed inside the casing

Exposed Ferrite impeders – around 10-15% of the end of the ferrite protrudes from the casing

We have standard male imperial couplings but can offer metric or other threads on request.

Impeders are available in length options of 230mm, 330mm & 430mm.

Impeder Cooling: Alle unsere Impeder sind so konzipiert, dass sie eine effektive Kühlung und den Schutz des Ferritkerns im Inneren des Impeders gewährleisten. Eine effiziente Kühlung des Ferrits ist wichtig, um die Schweißleistung zu maximieren und stabile Parameter für die Produktqualität aufrechtzuerhalten. Das Kühlmittel sollte sauber und vorzugsweise gefiltert sein. Unter den meisten Betriebsbedingungen sorgt ein Druck für ausreichende Kühlung. Der Kühlmitteldurchflussbedarf variiert stark aufgrund der Eingangstemperatur, der Schweißleistung, der Frequenz und der Geometrie des Schweißbereichs. In Situationen mit hoher Leistungsdichte und bei hohen Umgebungstemperaturen kann ein kleiner Kühler für das Kühlmittel des Impeders und der Arbeitsspule die Effizienz erheblich verbessern. Cooling by air or other gas is not recommended, but can be useful in special situations where the presence of water inside the tube cannot be tolerated. Gas, such as nitrogen, have a density that is at least 1,000 times less than that of water, so coolant volume must be increased accordingly.

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Wirbelstrommaschine

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

Spare Parts and Consumble Parts

-

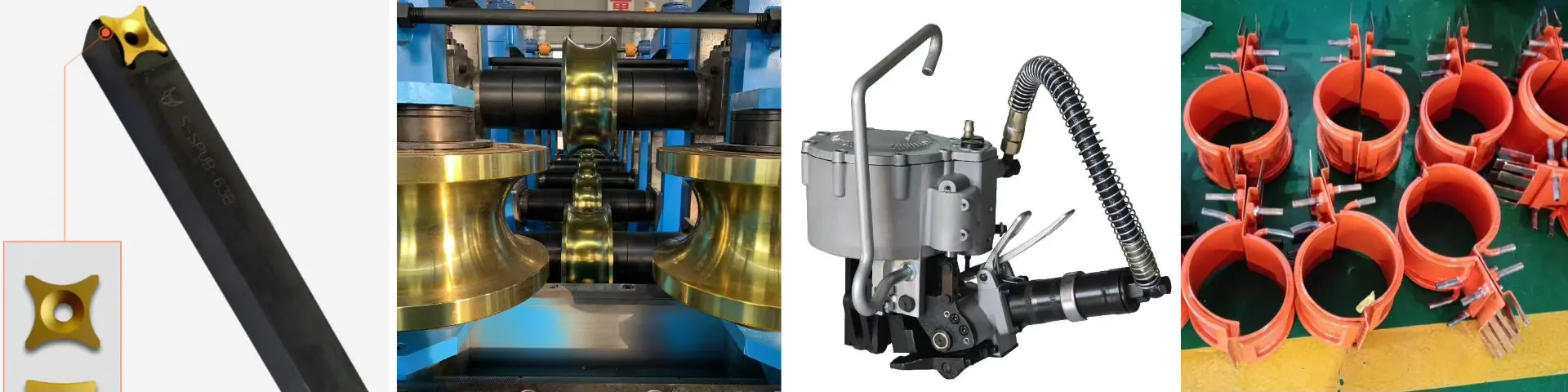

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Warum uns wählen?

-

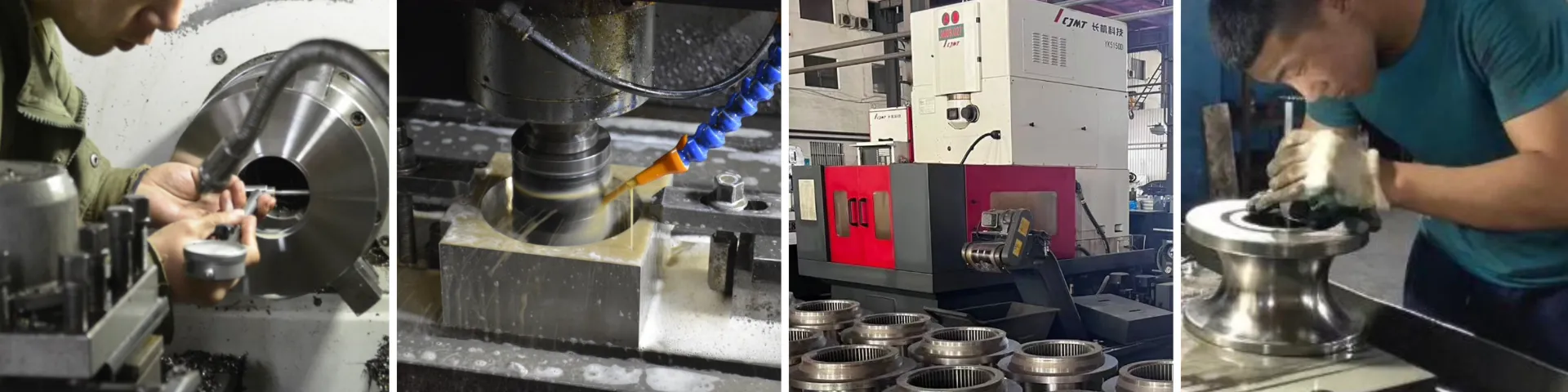

1.Leading Technology, Reliable Quality, Excellent Service! Optimiertes Design, hochwertige Materialauswahl! Garantie des Wärmebehandlungsprozesses!

-

2.Spiral bevel gear, drum gear coupling and carburization. Abschrecken der Zahnräder. Angetriebenes System stabil, effizient und tragbar mit geringerer Geräuschentwicklung.

-

3.High precision wear resisting and Long life of toolings. Alle Drehmaschinen und Schlüsselnuten werden CNC-gefräst und positioniert.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Kundendienst

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5,24 Stunden für die Antwort des Technikers.

- 6. Ihre Geschäftsbeziehung mit uns wird gegenüber Dritten vertraulich behandelt.

- 7. We welcome customers to visit our factory anytime.

Tel:86-15176910262

Tel:86-15176910262