제품 설명

1. Overview

The Pipe Hydro Tester Machine is used to test the pressure resistance and sealing performance of steel pipes, welded pipes, or seamless tubes before delivery. It injects high-pressure water into the pipe to check for leakage or deformation under a set pressure.

2. Working Principle

-

The pipe is clamped and fixed into position.

-

Sealing heads tightly close both pipe ends.

-

A high-pressure pump fills the pipe with water and pressurizes it to a preset value.

-

The system maintains this pressure (e.g., for 10 seconds) and monitors for pressure drops or leaks.

-

After testing, the water is discharged, and the pipe is released.

3. Main Technical Parameters (Example)

| Parameter |

Value Range |

| Applicable Pipe OD |

20mm – 630mm (customizable) |

| Pipe Length |

2m – 18m (as per requirement) |

| Max Test Pressure |

10 MPa – 70 MPa |

| Test Medium |

Clean water (can be anti-rust treated) |

| Pressure Holding Time |

3 – 60 seconds (adjustable) |

| Pressurization Method |

High-pressure plunger or booster pump |

| Clamping System |

Hydraulic / Electric / Mechanical |

| Control System |

Manual or PLC + Touch Screen |

| Operation Mode |

Single / Dual / Multi-station |

| Safety Features |

Overpressure alarm, relief valve, emergency stop |

4. Main Components

-

Main Frame: Supports the clamping and pressurizing systems.

-

High-Pressure Pump Station: Supplies the required pressurized water.

-

Clamping Mechanism: Holds the pipe securely during the test.

-

Sealing Heads: Seal both ends of the pipe to contain pressure.

-

Hydraulic System: Drives the clamping and sealing mechanisms.

-

Control Panel: Manual or PLC-based for automated control and data handling.

-

Pressure Sensors/Gauges: Monitor pressure in real-time.

-

Drainage System: Discharges test water after testing is complete.

5. Operation Procedure (Example for Automated System)

Load & Align: Place the pipe into position via crane or loading table.

Clamp & Seal: Automatically clamp and seal both ends of the pipe.

Pressurize & Hold: Initiate pressurization up to the target pressure and hold.

Monitor & Evaluate: Detect pressure drop or leakage. Alarm if failed.

Drain & Unload: Discharge water, release pipe, and prepare for next cycle.

6. Maintenance & Inspection

| Item |

Frequency |

Description |

| Seal Inspection |

Daily |

Replace worn or aged seals |

| Filter Cleaning |

Weekly |

Ensure pump intake is free from debris |

| Pressure Sensor Calibration |

Monthly |

Check accuracy or replace if needed |

| Hydraulic Oil Change |

Every 6 mo. |

Ensure smooth operation of hydraulics |

| Safety System Check |

Daily |

Confirm emergency stop, relief valves |

7. Common Troubleshooting

| Issue |

Possible Cause |

Solution |

| Unable to Build Pressure |

Pump failure / Seal leak |

Check pump & seals |

| Pressure Fluctuation |

Leakage / Air in system |

Check fittings and vent air |

| Poor Clamping |

Low hydraulic pressure |

Refill oil / check solenoid valves |

| Control Failure |

Wiring / PLC error |

Inspect circuits & software |

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. 와류기

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

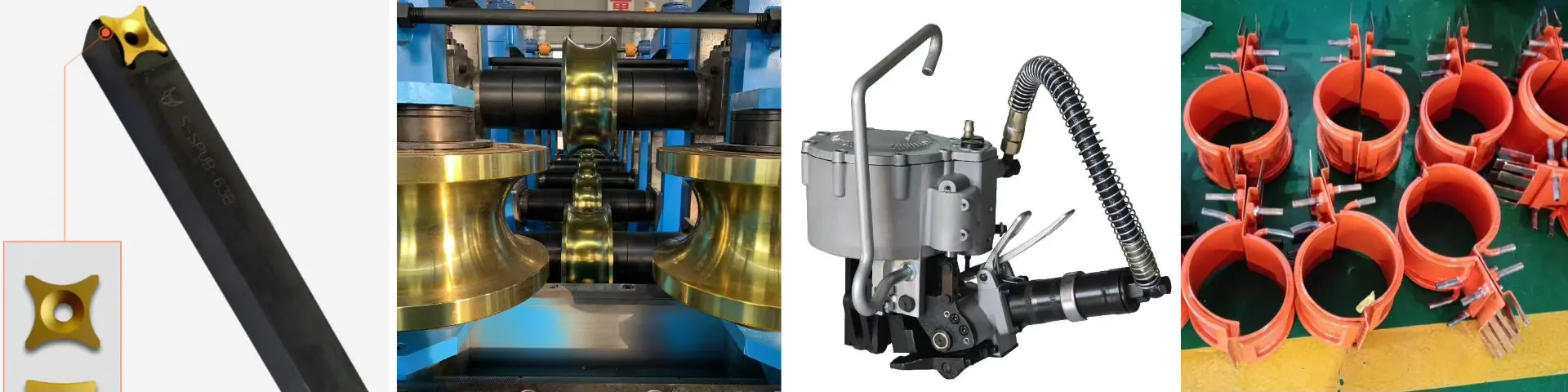

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

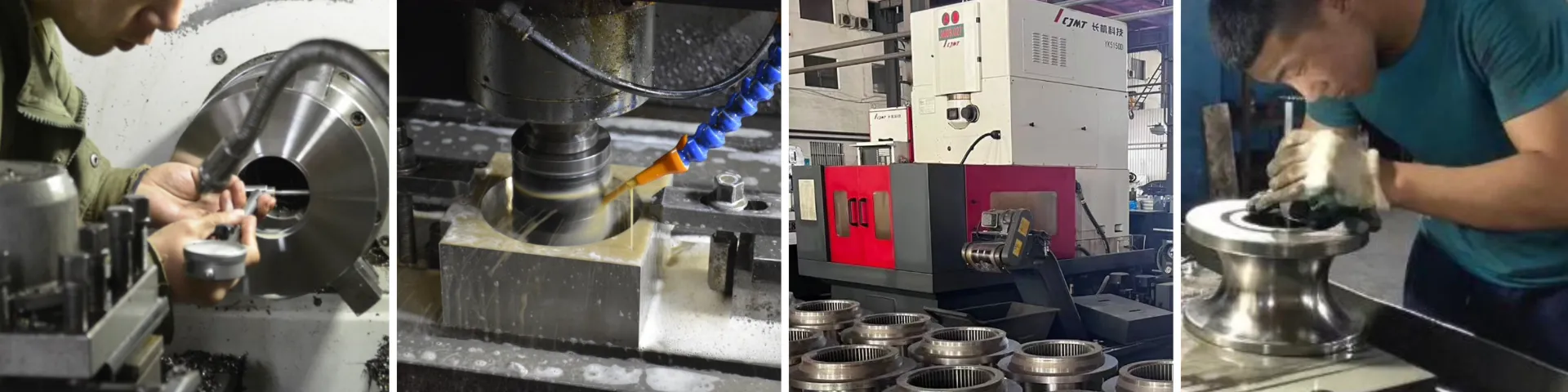

- 왜 우리를 선택하시나요?

-

1.Leading Technology, Reliable Quality, Excellent Service! 최적화된 디자인, 고품질 소재 선택! 열처리 과정 보증!

-

2.Spiral bevel gear, drum gear coupling and carburization. 기어 이빨 담금질. 구동 시스템은 안정적이고 효율적이며 소음이 적고 내구성이 뛰어납니다.

-

3.High precision wear resisting and Long life of toolings. 모든 기계 선반과 키 홈은 CNC로 위치가 지정되고 밀링됩니다.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

애프터서비스

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 엔지니어가 응답하기까지 5.24시간이 걸립니다.

- 6. 귀사와 당사 간의 사업 관계는 모든 제3자에게 비밀로 유지됩니다.

- 7. We welcome customers to visit our factory anytime.