Product Description

1. Overview

The Pipe Hydro Tester Machine is used to test the pressure resistance and sealing performance of steel pipes, welded pipes, or seamless tubes before delivery. It injects high-pressure water into the pipe to check for leakage or deformation under a set pressure.

2. Working Principle

-

The pipe is clamped and fixed into position.

-

Sealing heads tightly close both pipe ends.

-

A high-pressure pump fills the pipe with water and pressurizes it to a preset value.

-

The system maintains this pressure (e.g., for 10 seconds) and monitors for pressure drops or leaks.

-

After testing, the water is discharged, and the pipe is released.

3. Main Technical Parameters (Example)

| Parameter |

Value Range |

| Applicable Pipe OD |

20mm – 630mm (customizable) |

| Pipe Length |

2m – 18m (as per requirement) |

| Max Test Pressure |

10 MPa – 70 MPa |

| Test Medium |

Clean water (can be anti-rust treated) |

| Pressure Holding Time |

3 – 60 seconds (adjustable) |

| Pressurization Method |

High-pressure plunger or booster pump |

| Clamping System |

Hydraulic / Electric / Mechanical |

| Control System |

Manual or PLC + Touch Screen |

| Operation Mode |

Single / Dual / Multi-station |

| Safety Features |

Overpressure alarm, relief valve, emergency stop |

4. Main Components

-

Main Frame: Supports the clamping and pressurizing systems.

-

High-Pressure Pump Station: Supplies the required pressurized water.

-

Clamping Mechanism: Holds the pipe securely during the test.

-

Sealing Heads: Seal both ends of the pipe to contain pressure.

-

Hydraulic System: Drives the clamping and sealing mechanisms.

-

Control Panel: Manual or PLC-based for automated control and data handling.

-

Pressure Sensors/Gauges: Monitor pressure in real-time.

-

Drainage System: Discharges test water after testing is complete.

5. Operation Procedure (Example for Automated System)

Load & Align: Place the pipe into position via crane or loading table.

Clamp & Seal: Automatically clamp and seal both ends of the pipe.

Pressurize & Hold: Initiate pressurization up to the target pressure and hold.

Monitor & Evaluate: Detect pressure drop or leakage. Alarm if failed.

Drain & Unload: Discharge water, release pipe, and prepare for next cycle.

6. Maintenance & Inspection

| Item |

Frequency |

Description |

| Seal Inspection |

Daily |

Replace worn or aged seals |

| Filter Cleaning |

Weekly |

Ensure pump intake is free from debris |

| Pressure Sensor Calibration |

Monthly |

Check accuracy or replace if needed |

| Hydraulic Oil Change |

Every 6 mo. |

Ensure smooth operation of hydraulics |

| Safety System Check |

Daily |

Confirm emergency stop, relief valves |

7. Common Troubleshooting

| Issue |

Possible Cause |

Solution |

| Unable to Build Pressure |

Pump failure / Seal leak |

Check pump & seals |

| Pressure Fluctuation |

Leakage / Air in system |

Check fittings and vent air |

| Poor Clamping |

Low hydraulic pressure |

Refill oil / check solenoid valves |

| Control Failure |

Wiring / PLC error |

Inspect circuits & software |

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Eddy current machine

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

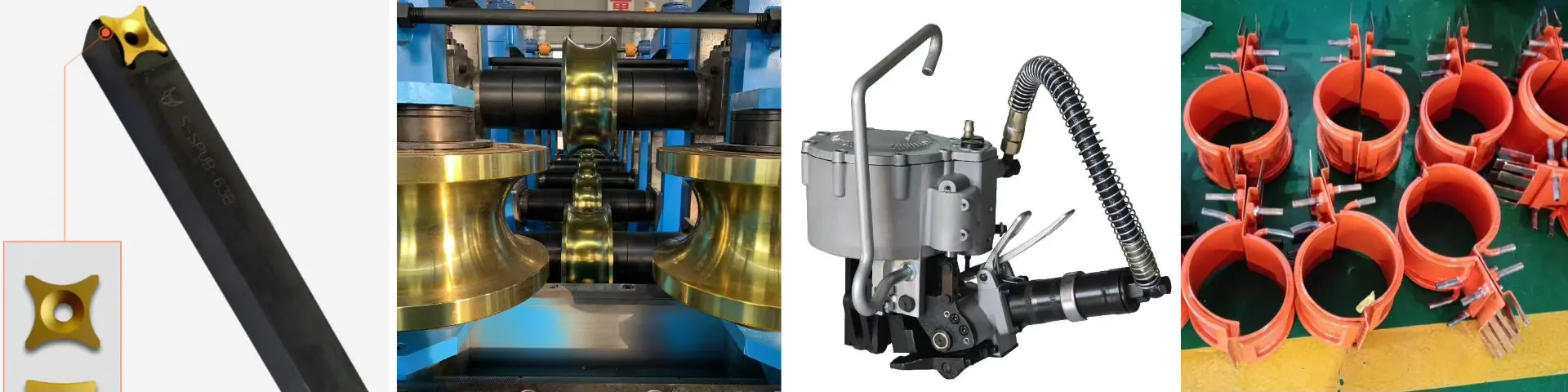

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Why Choose Us?

-

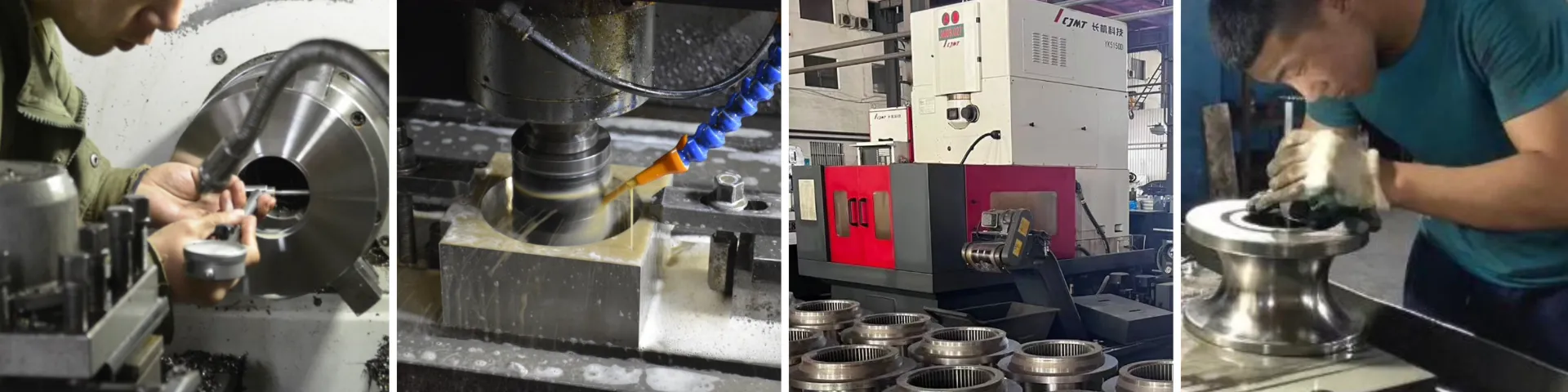

1.Leading Technology, Reliable Quality, Excellent Service! Optimized Design, High quality material select! Heat treatment process guarantee!

-

2.Spiral bevel gear, drum gear coupling and carburization. Gear teeth quenching. Driven system stable, efficient and wearable with lower noise.

-

3.High precision wear resisting and Long life of toolings. All the machine Lathes, Key Grooves are positioned and Milled by CNC.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

After-sales service

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5 .24 hours for engineer response.

- 6.Your business relationship with us will be confidential to any third party.

- 7. We welcome customers to visit our factory anytime.

Tel:86-15176910262

Tel:86-15176910262