-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Advanced Pipe Mill Line High-Speed Precision Production

Jun . 03, 2025 22:33

- Industrial evolution of pipe manufacturing technology

- Performance benchmarks through production metrics

- Engineering breakthroughs in welded pipe systems

- Global manufacturer capability analysis

- Custom configuration options by application

- Implementation success across industries

- Emerging innovations in tube production

(pipe mill line)

Industrial Evolution of Pipe Mill Line Manufacturing

The pipe mill line

industry has transformed dramatically from rudimentary manual operations to sophisticated continuous processing systems. Advancements in high-frequency welding technology now enable production speeds exceeding 120 meters per minute with near-zero defect rates. Modern tube mill production lines incorporate inline inspection systems that utilize automated ultrasonic testing with sensitivity down to 0.25mm flaws while maintaining maximum throughput.

Key technological milestones include the integration of AI-powered predictive maintenance protocols that reduce unplanned downtime by 45%. Real-time thickness monitoring systems detect variations down to ±0.05mm during high-speed operation. These innovations transform conventional pipe manufacturing into a precisely calibrated industrial workflow with consistent output quality regardless of material grade or dimensional specifications.

Performance Benchmarks Through Production Metrics

Modern welded pipe production lines achieve unprecedented operational efficiency with documented industry records:

- Material yield rates improved to 98.7% through precision edge trimming

- Energy consumption reduced by 32% using regenerative drive systems

- Changeover times decreased to 18 minutes for diameter/specification switches

Longitudinal consistency in tube mill production demonstrates remarkable precision with wall thickness tolerances maintained within ±3.5% and ovality controlled below 0.8% of nominal diameter. Operational efficiency peaks at 92% equipment effectiveness (OEE) for continuous 24/7 production cycles lasting 45-60 days between scheduled maintenance intervals.

Engineering Breakthroughs in Welded Pipe Systems

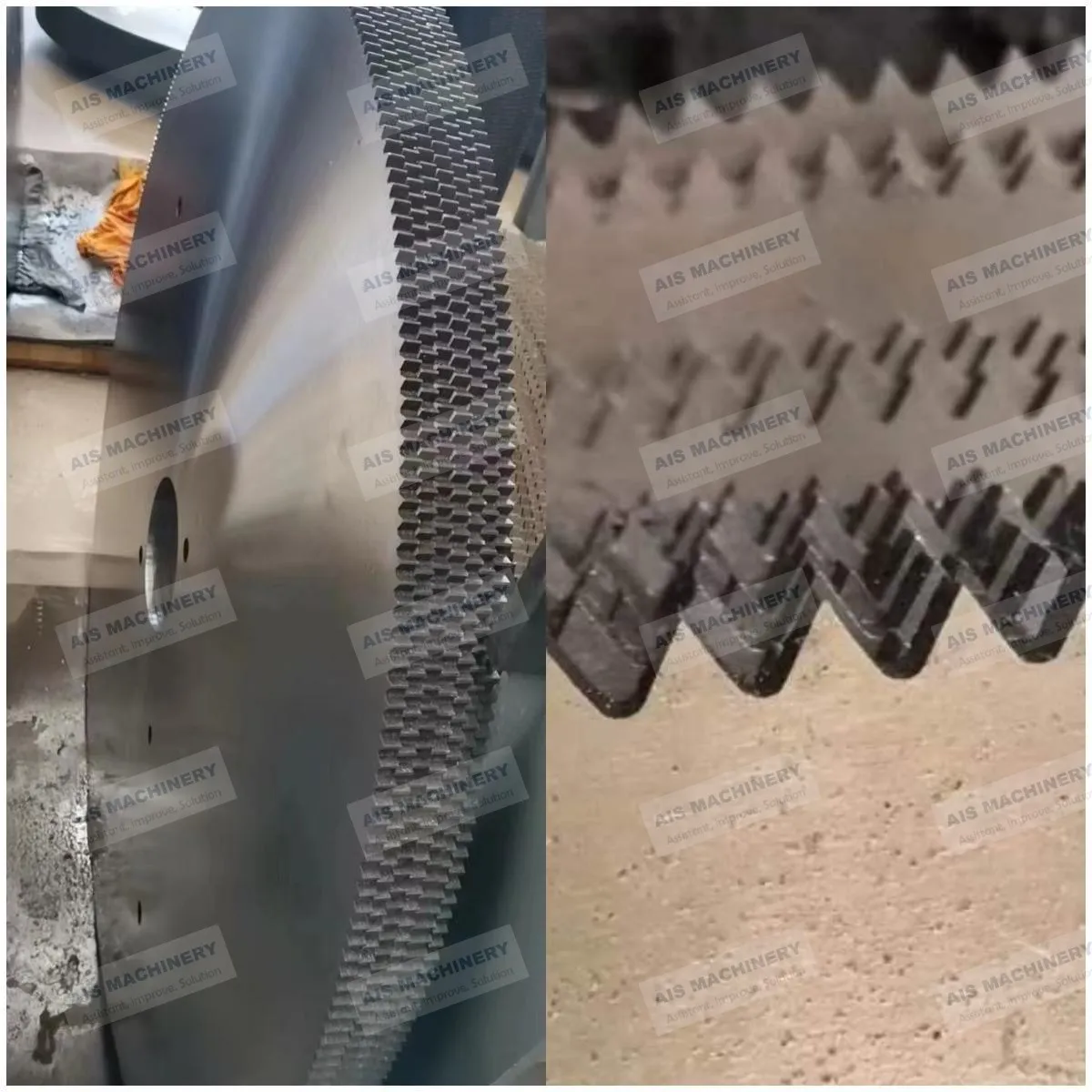

Contemporary welded pipe production lines incorporate multiple proprietary technologies that elevate output quality. Advanced forming sections utilize 12-roll cassette systems that achieve optimal strip contouring with ≤0.1% springback. High-frequency induction welding applies localized temperatures exceeding 1250°C in precisely controlled thermal zones, creating bonds with material integrity matching virgin steel.

Seam annealing immediately follows welding with micro-tempering that refines grain structures, resulting in hardness variations below 3 HRC across weld zones. Inline quality verification systems include phased array ultrasonic testing with 256-channel resolution and automated digital radiography that captures imperfections beyond 0.3% of wall thickness at production velocities up to 100 m/min.

Global Manufacturer Capability Analysis

| Manufacturer | Max OD (mm) | Production Speed (m/min) | Wall Precision | Technology Portfolio |

|---|---|---|---|---|

| TechSteel Systems | 508 | 145 | ±2.5% | AI thickness control, laser calibration |

| MetForm International | 406 | 110 | ±3.1% | HFI welding, multi-zone annealing |

| PrecisionTube Group | 610 | 85 | ±4.2% | Traditional ERW, offline inspection |

Leading manufacturers differentiate through application-specific R&D investments averaging 6.2% of annual revenue. Technology leaders employ proprietary control algorithms that optimize forming pressure dynamically, adjusting for material variances within same-coil production. Such innovations reduce dimensional rejection rates below 0.08% even when processing high-strength API grades up to X80 specification.

Custom Configuration Options by Application

Specialized industrial sectors require tailored pipe mill line configurations to meet application-specific standards:

Structural Applications: Mills equipped with 8-stage forming sections producing rectangular/square profiles from 30×15mm to 250×125mm with corner radii control within 0.5mm tolerance

Petrochemical Sector: Systems incorporating post-weld normalizing chambers achieving 95% phase transformation consistency across API 5L grades. Multiple nondestructive testing modules provide full volumetric inspection compliant with ASME Section V requirements

Sanitary Processing: Electropolishing stations integrated inline with surface finishing achieving Ra ≤0.4μm. Entirely sealed production environments maintain ISO Class 6 cleanliness throughout fabrication

Implementation Success Across Industries

Major projects demonstrate operational excellence enabled by advanced tube mill production lines:

A North American energy infrastructure project achieved 17% cost reduction deploying high-speed pipe mill lines producing 48,000 metric tons of 18" OD transmission pipe annually. Adaptive control systems maintained dimensional stability when switching between X60-X70 grades without production interruption.

European automotive manufacturers documented 92% material utilization rates after implementing dedicated tube mills for exhaust system components. Automated profile switching allowed production of 27 distinct diameter/thickness combinations during single shift operations, reducing work-in-progress inventory by 34 days annually.

Future Innovations in Pipe Mill Line Technology

Emerging pipe mill line technologies will transform production capabilities through machine learning applications and sustainable engineering. Predictive quality control systems utilizing neural networks will forecast dimensional stability 15 meters ahead of actual measurement points, enabling micro-corrections at forming stages. Industry 4.0 connectivity will enable remote synchronization between mills and customer inventory systems achieving Just-In-Time production aligned with consumption patterns.

Next-generation tube mill production lines will feature direct energy deposition units that functionally grade materials during continuous processing. This allows single-pass production of bimetallic tubing with corrosion-resistant cladding precision-applied to structural cores, eliminating post-production treatments. Simultaneously, hydrogen-ready mills will emerge for manufacturing pipes with seamless integrity for transporting volatile compounds under extreme pressure conditions.

(pipe mill line)

FAQS on pipe mill line

What is a pipe mill line?

Q: How does a pipe mill line transform raw materials into finished pipes?

A: A pipe mill line feeds steel coils through forming, welding, and sizing stations to create seamless tubes. Advanced welding technologies like HF or TIG ensure precision joining in continuous production. Final stages include cutting, testing, and surface finishing for industry-ready pipes.

What components define a welded pipe production line?

Q: What key machinery is essential for welded pipe production?

A: Critical equipment includes uncoilers to feed metal coils, forming rollers to shape strips into cylinders, and high-frequency welders to fuse seams. Automated ultrasonic testers and sizing mills ensure dimensional accuracy and weld integrity before final cutting to specified lengths.

How efficient is a tube mill production line?

Q: What production speeds can modern tube mill lines achieve?

A: Automated tube mills operate at speeds exceeding 100 meters per minute, varying by pipe diameter and material thickness. Computerized controls synchronize forming, welding, and finishing stages for minimal downtime. This enables mass production with consistent quality across 24/7 operations.

What industries rely on welded pipe production lines?

Q: Which sectors benefit most from welded pipe manufacturing systems?

A: Construction, oil/gas, and automotive industries extensively use welded pipes for structural, plumbing, and fluid transport needs. Production lines customize pipes with coatings, threading, or bevelling to meet sector-specific standards like API 5L for pipelines or ASTM A53 for structural applications.

How do tube mill lines maintain quality control?

Q: What quality checks are integrated into tube mill production processes?

A: In-line ultrasonic/eddy current testers detect weld defects in real-time, while laser gauges monitor wall thickness and diameter. Automated sorting rejects substandard sections, ensuring compliance with ISO 9001 or customer specifications before packing. Traceability systems log data for each produced pipe.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!