1. Overview

The loading trolley is a critical component of the front-end coil feeding system in an ERW tube mill line. It is primarily used to transport steel coils safely and smoothly from the ground to the centerline of the uncoiler spindle. Its purpose is to improve feeding efficiency, reduce manual intervention, and ensure accurate coil positioning, thereby ensuring stable raw material input for subsequent uncoiling, leveling, shearing, or forming processes.

2. Main Functions

-

Coil Carrying: Designed to bear heavy-duty steel coils with large outer diameters and high weights.

-

Longitudinal Movement: Moves forward and backward along ground rails to position the coil precisely in front of the uncoiler.

-

Lifting and Alignment: Equipped with a hydraulic or motorized lifting system to adjust coil height and align with the uncoiler spindle.

-

Automatic Centering (optional): Works with limiters or sensors to assist in transverse centering of the coil.

-

Linked Control: Can be electrically interlocked with the uncoiler for improved automation and operational safety.

3. Structural Components

-

Main Frame: Welded steel structure with high strength and rigidity.

-

Rail System: Ground-mounted rails for guiding the trolley in linear motion.

-

Drive System: Electric motor with gearbox or hydraulic drive, equipped with brake function.

-

Lifting Mechanism: Hydraulic cylinder, chain, or screw-based system ensuring stable and precise elevation.

-

Control System: Operated via control box, remote controller, or integrated with the central control panel.

-

Safety Devices: Includes limit switches and buffers for safe and controlled movement.

4. Technical Parameters (Typical Values – Subject to Design or Contract)

| Item |

Parameter Range |

| Max Coil Weight |

3–20 tons (customizable) |

| Coil Width Range |

300–1600 mm |

| Coil Outer Diameter |

Ø800–Ø2000 mm |

| Travel Speed |

6–15 m/min |

| Lifting Stroke |

300–600 mm |

| Control Mode |

Manual / Semi-automatic / Linked |

| Drive Type |

Electric / Hydraulic |

5. Application Description

In practical operation, the steel coil is first lifted and placed onto the loading trolley platform using a crane. The trolley then travels along the rails to the uncoiler’s centerline. Simultaneously, the lifting mechanism adjusts the coil height to align with the spindle. After the coil is successfully loaded onto the uncoiler, the trolley returns to its initial position to wait for the next loading cycle. The entire operation is stable, safe, and efficient, making the loading trolley an indispensable auxiliary device in modern welded pipe production lines.

-

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Машина вихретокового контроля

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

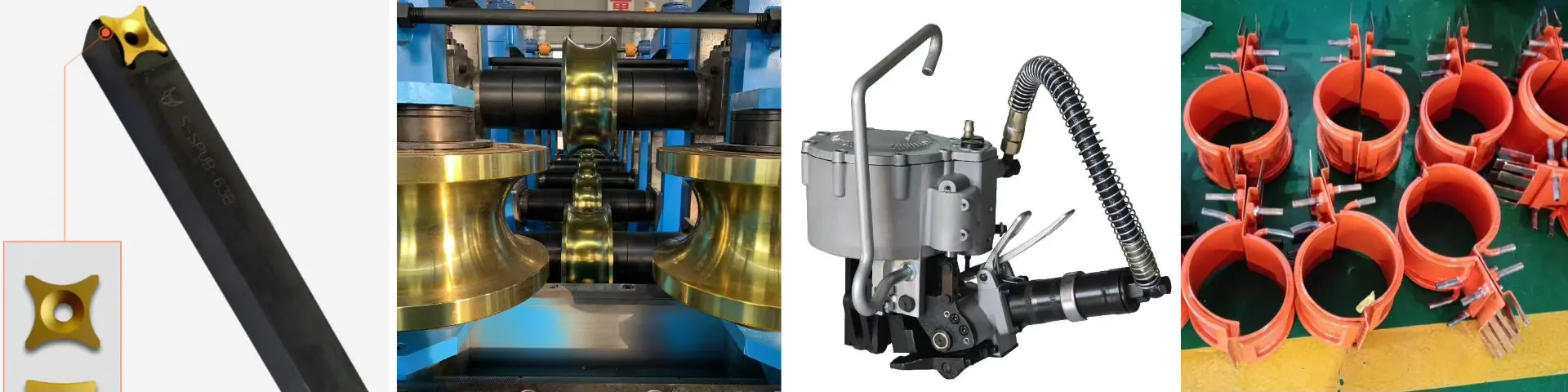

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Почему стоит выбрать нас?

-

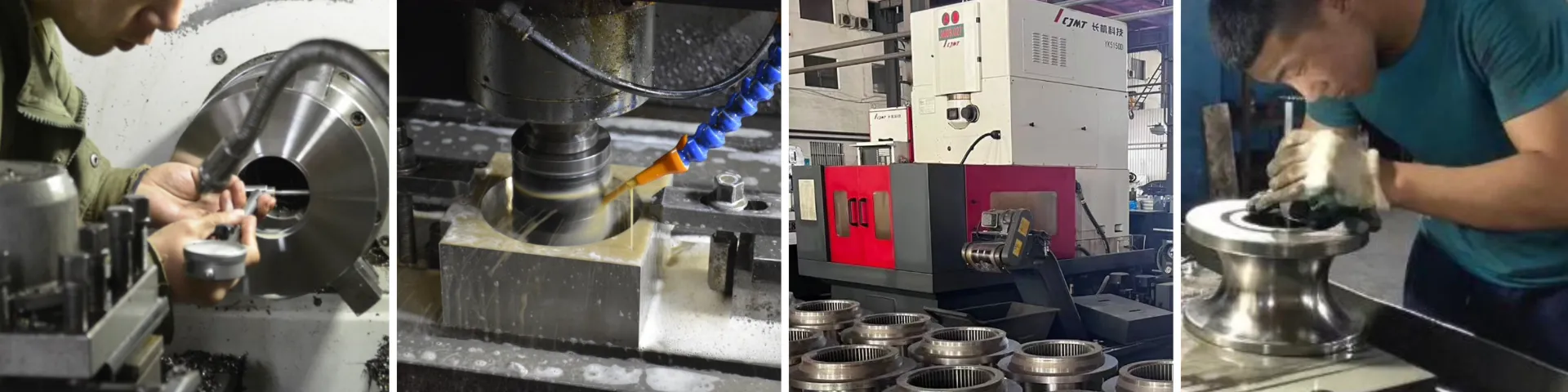

1.Leading Technology, Reliable Quality, Excellent Service! Оптимизированный дизайн, выбор высококачественных материалов! Гарантия процесса термообработки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Закалка зубьев шестерен. Приводная система стабильна, эффективна и удобна в использовании с низким уровнем шума.

-

3.High precision wear resisting and Long life of toolings. Все токарные станки, шпоночные пазы позиционируются и фрезеруются с помощью ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Послепродажное обслуживание

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5,24 часа на ответ инженера.

- 6.Ваши деловые отношения с нами будут конфиденциальны для любых третьих лиц.

- 7. We welcome customers to visit our factory anytime.

Tel:86-15176910262

Tel:86-15176910262