Описание продукта

✅ 1. Introduction

The Induction Coil is a critical component in a High Frequency (HF) Welding Machine, primarily used for pipe and tube welding. It generates a high-frequency electromagnetic field that induces eddy currents in the pipe's edges, causing them to heat up and fuse under pressure—without direct contact.

✅ 2. Подробная информация о продукте

-

Product Name: Induction Coil / Welding Coil

-

Приложение: Seam welding of steel, stainless steel, aluminum, and copper tubes or profiles

-

Frequency Range: 100 kHz – 800 kHz (typically)

-

Cooling Type: Water-cooled (inner copper tube or spiral structure)

-

Compatibility: Solid-state and vacuum tube HF welders

✅ 3. Main Components

-

Induction Loop / Copper Coil – Forms the electromagnetic field

-

Cooling Tube – Circulates water to prevent overheating

-

Support Housing – Provides insulation and structural integrity

-

Connection Terminals – Interface with the HF generator

-

Ferrite Cores (optional) – Improve magnetic field focus and efficiency

✅ 4. Comparison of Induction Coil Types for HF Welding

| Coil Type |

Structural Features |

Application Scenarios |

Advantages |

Disadvantages |

| Spiral Coil |

Multiple turns of round or oval copper tube |

Small to medium pipe diameters |

Uniform heating, widely applicable |

Less efficient for large-diameter pipes |

| U-Shaped Coil |

U-shape copper tube, open side faces weld seam |

Medium-diameter pipes, focused heating |

Focused seam heating, fast welding |

Limited heating area, needs precise alignment |

| Saddle-Type Coil |

Shaped like a saddle to fit the pipe contour |

Large-diameter or shaped tubes |

Wide heating area, suitable for irregular shapes |

Complex design, higher cost |

| Ferrite Core Coil |

With ferrite cores to enhance magnetic focusing |

High-efficiency HF welding |

Increases heating efficiency, reduces energy loss |

Ferrite is fragile, requires careful handling |

| Adjustable Coil |

Adjustable structure to fit various pipe sizes |

Multi-size production lines |

Highly flexible and versatile |

Complex structure, requires experienced handling |

📌 Selection Tips

-

Small pipes (<50 mm): Spiral coil is recommended for its simplicity and cost-effectiveness.

-

Medium pipes (50–150 mm): U-shaped coils offer efficient, focused heating.

-

Large or irregular pipes (>150 mm): Saddle coils cover a wider area and handle complex profiles.

-

High-efficiency requirements: Ferrite core coils help reduce energy loss and improve heat focus.

-

Versatile production lines: Adjustable coils are ideal for lines requiring flexibility in pipe diameters.

✅ 5. Working Principle

-

The HF generator sends current to the induction coil.

-

A strong high-frequency magnetic field is created around the coil.

-

As the pipe passes through the coil, eddy currents are induced at the edge surfaces.

-

These currents generate localized heat at the pipe’s seam (skin effect + proximity effect).

-

When the pipe edges reach the fusion point, squeeze rollers press them together to form a solid weld without filler material.

✅ 6. Technical Parameters (Typical Values)

| Parameter |

Value Range |

| Frequency Range |

100 – 800 kHz |

| Input Power Capacity |

50 – 600 kW (depends on system) |

| Coil Inner Diameter |

20 mm – 300 mm (customizable) |

| Coil Type |

Spiral, U-shape, Saddle, or Custom Form |

| Cooling Method |

Water Cooling (2–5 L/min) |

| Max Operating Temperature |

~200–300°C (with active cooling) |

| Coil Material |

High-purity copper with insulation |

✅ 7. Summary

-

The induction coil is a key part of HF welding, enabling non-contact, high-speed seam welding for pipe production.

-

Coil shape and size are customizable to match pipe diameter and welding specifications.

-

High durability, excellent thermal conductivity, and magnetic field efficiency are critical for stable, continuous production.

-

Proper cooling and maintenance significantly extend coil life and welding consistency.

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Машина вихретокового контроля

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

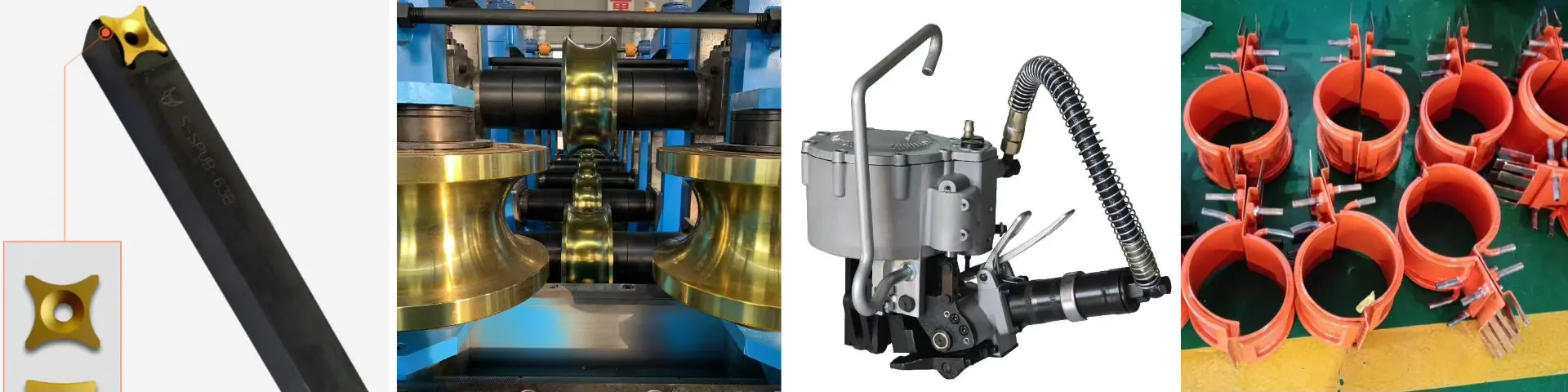

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

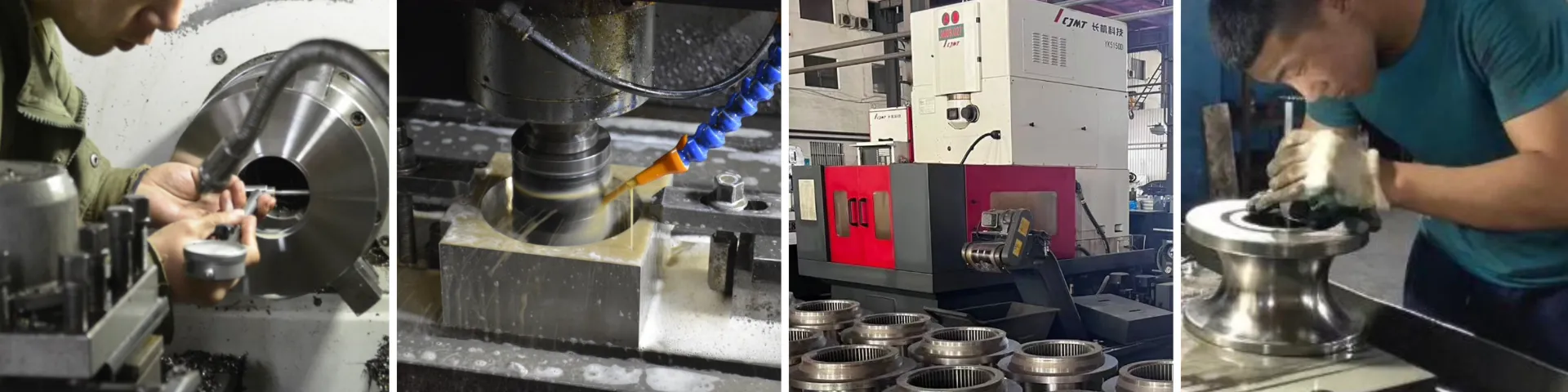

- Почему стоит выбрать нас?

-

1.Leading Technology, Reliable Quality, Excellent Service! Оптимизированный дизайн, выбор высококачественных материалов! Гарантия процесса термообработки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Закалка зубьев шестерен. Приводная система стабильна, эффективна и удобна в использовании с низким уровнем шума.

-

3.High precision wear resisting and Long life of toolings. Все токарные станки, шпоночные пазы позиционируются и фрезеруются с помощью ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Послепродажное обслуживание

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5,24 часа на ответ инженера.

- 6.Ваши деловые отношения с нами будут конфиденциальны для любых третьих лиц.

- 7. We welcome customers to visit our factory anytime.

Тел:86-15176910262

Тел:86-15176910262