✅ 1. Product Overview

The Horizontal Accumulator, also known as a Floor-Type Spiral Accumulator, is a dynamic coil storage system used in tube mills, slitting lines, and other continuous strip processing lines. Its main function is to buffer strip material during coil changeover or welding, ensuring non-stop production.

🌀 2. Working Principle & Storage Mode

This accumulator stores strip material horizontally in a serpentine loop layout. As the strip is fed from the uncoiler, it enters the accumulator and is guided through a series of rollers that form horizontal loops. These loops are stored along a linear bed or platform.

⚙️ 3. Technical Specifications (Sample Configuration)

🏗️ 4. Main Components

-

Loop Frame & Guide Rollers – Forms and guides horizontal strip loops.

-

Infeed & Outfeed Rollers – Feed strip in and out smoothly.

-

Tension Control System – Maintains strip tension via sensors.

-

Drive System – Includes servo or inverter motors for speed control.

-

Support Platform – Steel base frame or track for loop support.

-

PLC Control Cabinet – Centralized automation and logic control.

🧭 5. Application Scenarios

-

ERW tube and pipe mills

-

Steel strip slitting and recoiling lines

-

Cut-to-length and blanking lines

-

Continuous cold roll forming systems

-

Pickling and galvanizing lines

🔄 6. Comparison: Disc vs. Horizontal vs. Vertical Accumulator

🎯 7. How to Choose

-

Choose Disc Accumulator if:

-

You have limited floor and vertical space

-

Pipe diameter lower 127mm, thickness lower 5mm.

-

Buffering needs are moderate

-

Choose Horizontal Accumulator if:

-

You have enough floor space

-

Need long strip buffering (20m+)

-

Require good tension control but limited ceiling height

-

Choose Vertical Spiral Accumulator if:

COGNATIO ORNATUS

Nos omnem apparatum praebet ad sectionem molendini tubi viscus:

Coil Car

Singula et duplicata capita Un-coiler & hydraulica et pneumatica Un-coiler

Peeler et tenere in volumine arm

Machina adulatione

Automatic et Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

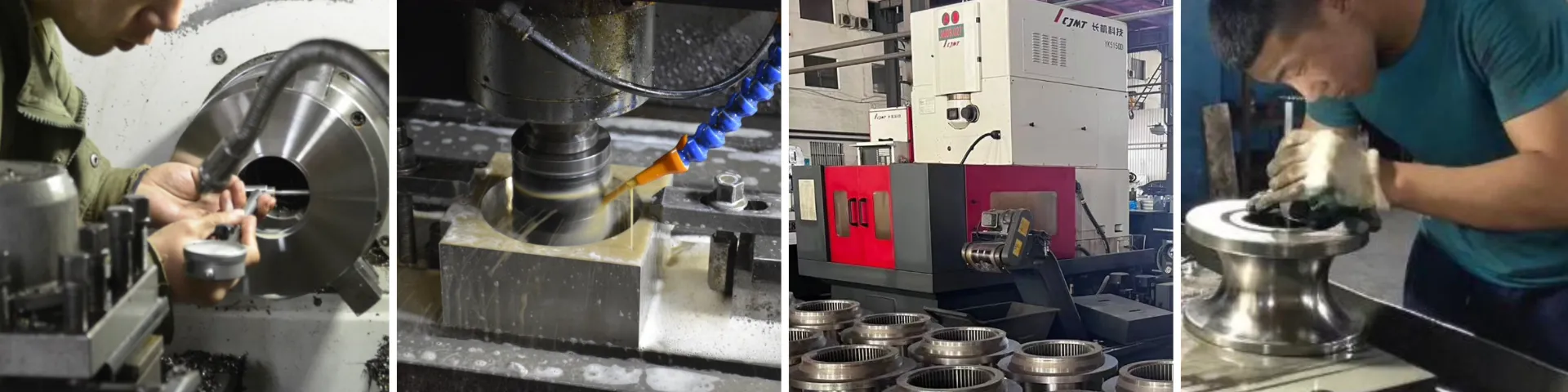

OPERA NOSTRA

Quid nos elige?

Ducens Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Caloris curatio processus spondet!

Calces cochleae revellere, orum calces copulatio et carburization.

Dentium calces exstingui.

Ratio acti stabilis, efficax et infatigabilis cum sonitu inferiori.

Summa subtilitate gerunt resistendo et longam tribulis vitam.

Tota machina Lathes, sulci Clavis a CNC cincta et molita sunt.

Post-Sales ministerium

1. Nos machinam trademus et documenta in tempore praebebunt ut machinam celeriter efficere possis

2. Praeparatio condiciones cum consummaveris, Ieiunium et professio nostra postsales servitii fectum ibit ad officinam tuam ut machinam instituat, manualem operantem tibi tribuat, et operarium tuum exerceat donec machinam bene operari possint.

3. Nos unum annum warantum et diuturnum technicum subsidium praebent.

4.Bene peritus & peritus baculus respondeat omnibus tuis quaestionibus Anglice et Sinice

5 .24 horae ad fectum responsum.

6. Negotium tuum cum nobis communicatio alicui tertiae parti secretior erit.

Qualitas Imperium

Unicum qualitatem habemus, quae materiam rudium materiarum bonam fac, et machinam nonumyter curet.

Tel:86-15176910262

Tel:86-15176910262