✅ 1. Product Overview

The Horizontal Accumulator, also known as a Floor-Type Spiral Accumulator, is a dynamic coil storage system used in tube mills, slitting lines, and other continuous strip processing lines. Its main function is to buffer strip material during coil changeover or welding, ensuring non-stop production.

🌀 2. Working Principle & Storage Mode

This accumulator stores strip material horizontally in a serpentine loop layout. As the strip is fed from the uncoiler, it enters the accumulator and is guided through a series of rollers that form horizontal loops. These loops are stored along a linear bed or platform.

⚙️ 3. Technical Specifications (Sample Configuration)

🏗️ 4. Main Components

-

Loop Frame & Guide Rollers – Forms and guides horizontal strip loops.

-

Infeed & Outfeed Rollers – Feed strip in and out smoothly.

-

Tension Control System – Maintains strip tension via sensors.

-

Drive System – Includes servo or inverter motors for speed control.

-

Support Platform – Steel base frame or track for loop support.

-

PLC Control Cabinet – Centralized automation and logic control.

🧭 5. Application Scenarios

-

ERW tube and pipe mills

-

Steel strip slitting and recoiling lines

-

Cut-to-length and blanking lines

-

Continuous cold roll forming systems

-

Pickling and galvanizing lines

🔄 6. Comparison: Disc vs. Horizontal vs. Vertical Accumulator

🎯 7. How to Choose

-

Choose Disc Accumulator if:

-

You have limited floor and vertical space

-

Pipe diameter lower 127mm, thickness lower 5mm.

-

Buffering needs are moderate

-

Choose Horizontal Accumulator if:

-

You have enough floor space

-

Need long strip buffering (20m+)

-

Require good tension control but limited ceiling height

-

Choose Vertical Spiral Accumulator if:

관계 장비

우리는 튜브 밀 진입 섹션에 필요한 모든 장비를 제공합니다:

코일카

싱글 및 더블 헤드 언코일러 및 유압 및 공압 언코일러

껍질 벗기고 롤 암을 잡아두세요

평탄화 기계

자동 및 반자동 전단기 및 맞대기 용접기

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

우리의 서비스

왜 우리를 선택하시나요?

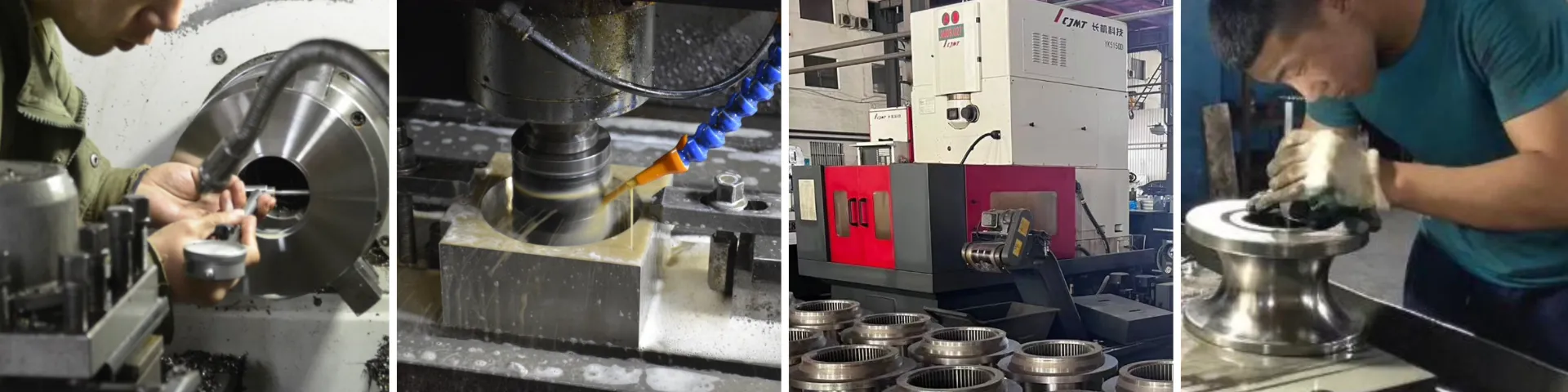

선도적인 기술, 신뢰할 수 있는 품질, 탁월한 서비스!

최적화된 디자인, 고품질 소재 선택!

열처리 과정 보증!

스파이럴 베벨기어, 드럼기어 커플링 및 탄화.

기어 이빨 담금질.

구동 시스템은 안정적이고 효율적이며 소음이 적고 내구성이 뛰어납니다.

고정밀 내마모성과 롤러의 긴 수명을 자랑합니다.

모든 기계 선반과 키 홈은 CNC로 위치가 지정되고 밀링됩니다.

애프터서비스

1. 우리는 기계를 제때 배달하고 문서를 제공하여 귀하가 기계를 빨리 받을 수 있도록 보장합니다.

2. 준비 조건을 마치면 빠르고 전문적인 애프터 서비스 엔지니어 팀이 귀사의 공장으로 가서 기계를 설치하고, 작동 설명서를 제공하고, 귀사 직원이 기계를 잘 작동할 수 있을 때까지 교육합니다.

3. 1년 보증과 평생 기술 지원을 제공합니다.

4. 잘 훈련되고 경험이 풍부한 직원이 영어와 중국어로 모든 문의에 답변합니다.

엔지니어가 응답하기까지 5.24시간이 걸립니다.

6. 귀사와 당사 간의 사업 관계는 모든 제3자에게 비밀로 유지됩니다.

품질 관리

당사는 원자재의 품질이 양호함을 확인하고 기계가 원활하게 작동하도록 보장하는 단일 품질 관리 부서를 갖추고 있습니다.