✅ 1. Product Overview

The Horizontal Accumulator, also known as a Floor-Type Spiral Accumulator, is a dynamic coil storage system used in tube mills, slitting lines, and other continuous strip processing lines. Its main function is to buffer strip material during coil changeover or welding, ensuring non-stop production.

🌀 2. Working Principle & Storage Mode

This accumulator stores strip material horizontally in a serpentine loop layout. As the strip is fed from the uncoiler, it enters the accumulator and is guided through a series of rollers that form horizontal loops. These loops are stored along a linear bed or platform.

⚙️ 3. Technical Specifications (Sample Configuration)

🏗️ 4. Main Components

-

Loop Frame & Guide Rollers – Forms and guides horizontal strip loops.

-

Infeed & Outfeed Rollers – Feed strip in and out smoothly.

-

Tension Control System – Maintains strip tension via sensors.

-

Drive System – Includes servo or inverter motors for speed control.

-

Support Platform – Steel base frame or track for loop support.

-

PLC Control Cabinet – Centralized automation and logic control.

🧭 5. Application Scenarios

-

ERW tube and pipe mills

-

Steel strip slitting and recoiling lines

-

Cut-to-length and blanking lines

-

Continuous cold roll forming systems

-

Pickling and galvanizing lines

🔄 6. Comparison: Disc vs. Horizontal vs. Vertical Accumulator

🎯 7. How to Choose

-

Choose Disc Accumulator if:

-

You have limited floor and vertical space

-

Pipe diameter lower 127mm, thickness lower 5mm.

-

Buffering needs are moderate

-

Choose Horizontal Accumulator if:

-

You have enough floor space

-

Need long strip buffering (20m+)

-

Require good tension control but limited ceiling height

-

Choose Vertical Spiral Accumulator if:

PERALATAN HUBUNGAN

Kami menyediakan semua peralatan untuk bagian masuk pabrik tabung:

Mobil Koil

Pembuka Kepala Tunggal dan Ganda, Pembuka Kepala Hidrolik dan Pneumatik

Pengupas dan tahan lengan gulung

Mesin Perata

Mesin Pemotong dan Las Ujung Otomatis dan Semi Otomatis

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

LAYANAN KAMI

Mengapa Memilih Kami?

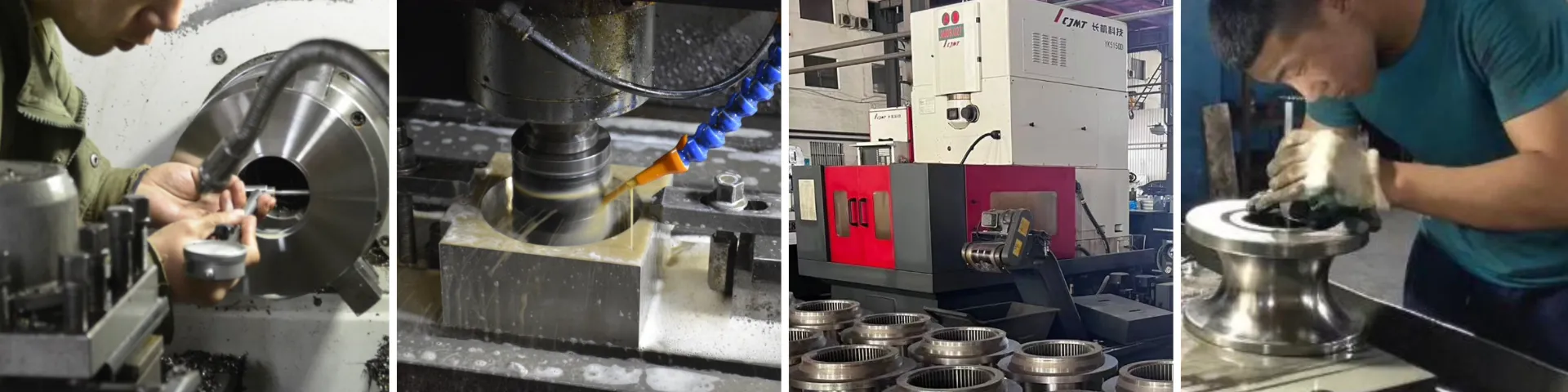

Teknologi Terkemuka, Kualitas Andal, Layanan Luar Biasa!

Desain yang dioptimalkan, Pilihan material berkualitas tinggi!

Jaminan proses perlakuan panas!

Roda gigi spiral bevel, kopling roda gigi drum dan karburisasi.

Pendinginan gigi roda gigi.

Sistem penggerak stabil, efisien, dan dapat dipakai dengan tingkat kebisingan lebih rendah.

Ketahanan aus dengan presisi tinggi dan umur rol yang panjang.

Semua mesin Bubut, Alur Kunci diposisikan dan digiling oleh CNC.

Layanan purna jual

1. Kami akan mengirimkan mesin dan memberikan dokumen tepat waktu untuk memastikan Anda bisa mendapatkan mesin dengan cepat

2. Setelah Anda menyelesaikan kondisi Persiapan, tim teknisi layanan purna jual kami yang cepat dan profesional akan pergi ke pabrik Anda untuk memasang mesin, memberi Anda manual pengoperasian, dan melatih karyawan Anda hingga mereka dapat mengoperasikan mesin dengan baik.

3. Kami menyediakan garansi satu tahun dan dukungan teknis seumur hidup.

4. Staf yang terlatih & berpengalaman akan menjawab semua pertanyaan Anda dalam bahasa Inggris dan Mandarin

5,24 jam untuk respon teknisi.

6.Hubungan bisnis Anda dengan kami akan dirahasiakan dari pihak ketiga mana pun.

Kontrol Kualitas

Kami memiliki departemen kualitas tunggal, yang memastikan bahan bakunya bagus, dan memastikan mesin berjalan lancar.

Telp:86-15176910262

Telp:86-15176910262