✅ 1. Product Overview

The Horizontal Accumulator, also known as a Floor-Type Spiral Accumulator, is a dynamic coil storage system used in tube mills, slitting lines, and other continuous strip processing lines. Its main function is to buffer strip material during coil changeover or welding, ensuring non-stop production.

🌀 2. Working Principle & Storage Mode

This accumulator stores strip material horizontally in a serpentine loop layout. As the strip is fed from the uncoiler, it enters the accumulator and is guided through a series of rollers that form horizontal loops. These loops are stored along a linear bed or platform.

⚙️ 3. Technical Specifications (Sample Configuration)

🏗️ 4. Main Components

-

Loop Frame & Guide Rollers – Forms and guides horizontal strip loops.

-

Infeed & Outfeed Rollers – Feed strip in and out smoothly.

-

Tension Control System – Maintains strip tension via sensors.

-

Drive System – Includes servo or inverter motors for speed control.

-

Support Platform – Steel base frame or track for loop support.

-

PLC Control Cabinet – Centralized automation and logic control.

🧭 5. Application Scenarios

-

ERW tube and pipe mills

-

Steel strip slitting and recoiling lines

-

Cut-to-length and blanking lines

-

Continuous cold roll forming systems

-

Pickling and galvanizing lines

🔄 6. Comparison: Disc vs. Horizontal vs. Vertical Accumulator

🎯 7. How to Choose

-

Choose Disc Accumulator if:

-

You have limited floor and vertical space

-

Pipe diameter lower 127mm, thickness lower 5mm.

-

Buffering needs are moderate

-

Choose Horizontal Accumulator if:

-

You have enough floor space

-

Need long strip buffering (20m+)

-

Require good tension control but limited ceiling height

-

Choose Vertical Spiral Accumulator if:

EQUIPO DE RELACIÓN

Proporcionamos todo el equipamiento para la sección de entrada del molino de tubos:

Carro de bobinas

Desenrollador de cabezal simple y doble y desenrollador hidráulico y neumático

Pelador y brazo de sujeción del rodillo

Maquina aplanadora

Cizalla y soldadora a tope automática y semiautomática

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

NUESTRO SERVICIO

¿Por qué elegirnos?

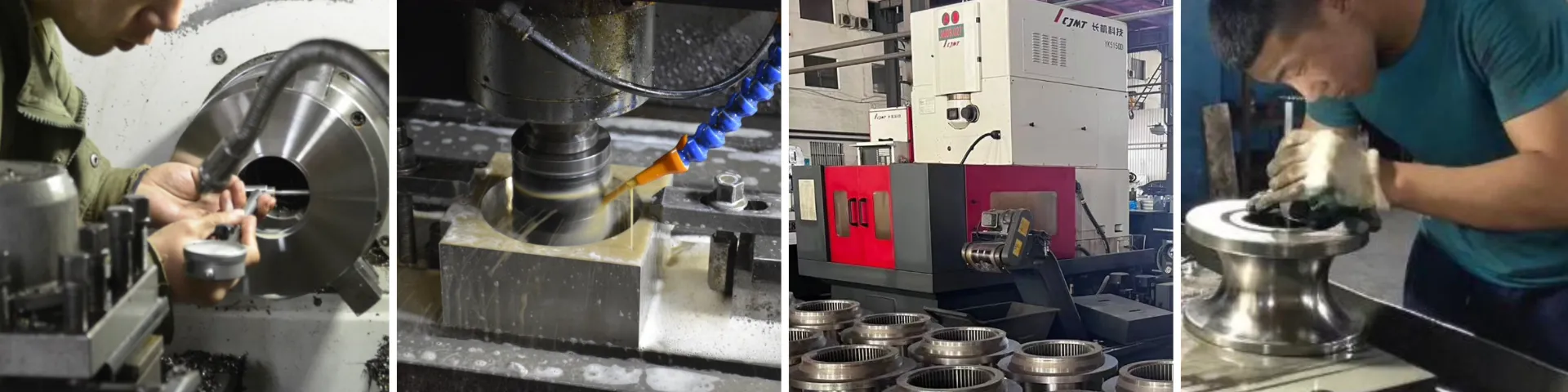

¡Tecnología líder, calidad confiable, excelente servicio!

¡Diseño optimizado, selección de materiales de alta calidad!

¡Garantía de proceso de tratamiento térmico!

Engranajes cónicos espirales, acoplamiento de engranajes de tambor y carburación.

Temple de dientes de engranajes.

Sistema accionado estable, eficiente y portátil con menor ruido.

Rodillos resistentes al desgaste de alta precisión y de larga vida útil.

Todos los tornos y ranuradores de las máquinas están posicionados y fresados mediante CNC.

Servicio postventa

1. Entregaremos la máquina y proporcionaremos los documentos a tiempo para asegurarnos de que pueda obtener la máquina rápidamente.

2. Cuando termine las condiciones de preparación, nuestro equipo de ingenieros de servicio posventa rápido y profesional irá a su fábrica para instalar la máquina, le entregará el manual de funcionamiento y capacitará a sus empleados hasta que puedan operar bien la máquina.

3. Ofrecemos un año de garantía y soporte técnico de por vida.

4. Nuestro personal capacitado y experimentado responderá todas sus consultas en inglés y chino.

5,24 horas para la respuesta del ingeniero.

6. Su relación comercial con nosotros será confidencial para cualquier tercero.

Control de calidad

Contamos con un departamento de calidad único, que se asegura de que el material de las materias primas sea bueno y garantiza que la máquina funcione sin problemas.

Teléfono: 86-15176910262

Teléfono: 86-15176910262