-

Tel:86-15176910262

Tel:86-15176910262

-

Search

steel pipe making machine manufacturer

Mar . 06, 2025 11:53

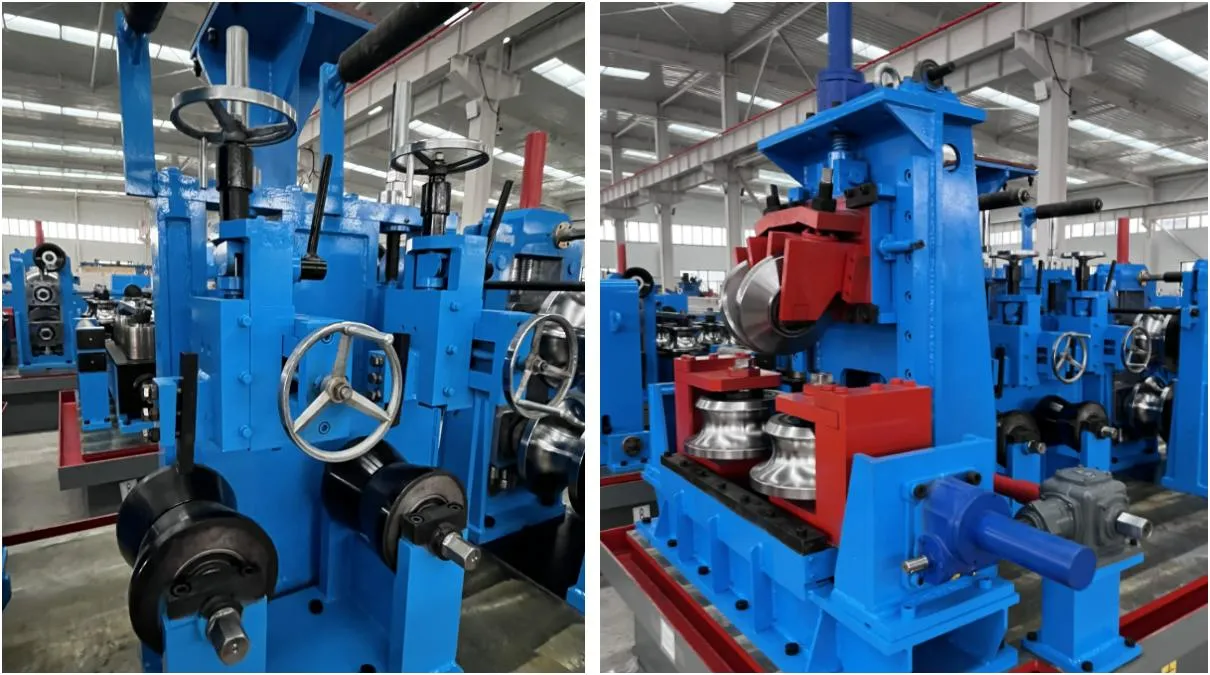

Steel pipe making machines are critical tools in industries such as construction, automotive, oil and gas, among others, where precision and durability of steel pipes are paramount. The journey of becoming a leading steel pipe making machine manufacturer demands a unique blend of experience, expertise, authoritativeness, and trustworthiness, all of which are essential for building and sustaining a reputable brand in this niche market.

Clients favor manufacturers who demonstrate a commitment to understanding and solving their specific challenges. Customization offers a compelling advantage; manufacturers that invest in cultural competence and technical adaptability, tailoring solutions to fit diverse client needs and regional specifications, invariably enhance their market appeal. This personalized approach fosters long-term partnerships rather than transactional relationships. Moreover, a forward-thinking steel pipe making machine manufacturer consistently invests in advanced training for their personnel. This ensures a team that is not only skilled but also capable of operating and maintaining the latest technologies, thus guaranteeing that every machine delivered is a product of best practices and state-of-the-art technology. It also translates to better client interactions, as knowledgeable staff can provide more than just support—they offer informed guidance throughout the purchasing and operational phases. In an industry where precision and efficiency are non-negotiable, the ability to provide robust, efficient, and innovative solutions is what sets a manufacturer apart. This demands a commitment to continuous improvement and a visionary approach to machine design and production processes. Manufacturers striving for excellence will cultivate a portfolio of diverse, high-performance machines—each engineered to cater to a broad array of industrial applications. In conclusion, a steel pipe making machine manufacturer that adeptly combines experience, expertise, authoritativeness, and trustworthiness inherently positions itself as a leader in the market. Clients today seek more than just machines—they seek partners in progress who will empower them with tools that define the future of their enterprises. A manufacturer who delivers on these four pillars not only meets but exceeds industry expectations, paving the way for sustainable growth and enduring influence in the steel pipe manufacturing realm.

Clients favor manufacturers who demonstrate a commitment to understanding and solving their specific challenges. Customization offers a compelling advantage; manufacturers that invest in cultural competence and technical adaptability, tailoring solutions to fit diverse client needs and regional specifications, invariably enhance their market appeal. This personalized approach fosters long-term partnerships rather than transactional relationships. Moreover, a forward-thinking steel pipe making machine manufacturer consistently invests in advanced training for their personnel. This ensures a team that is not only skilled but also capable of operating and maintaining the latest technologies, thus guaranteeing that every machine delivered is a product of best practices and state-of-the-art technology. It also translates to better client interactions, as knowledgeable staff can provide more than just support—they offer informed guidance throughout the purchasing and operational phases. In an industry where precision and efficiency are non-negotiable, the ability to provide robust, efficient, and innovative solutions is what sets a manufacturer apart. This demands a commitment to continuous improvement and a visionary approach to machine design and production processes. Manufacturers striving for excellence will cultivate a portfolio of diverse, high-performance machines—each engineered to cater to a broad array of industrial applications. In conclusion, a steel pipe making machine manufacturer that adeptly combines experience, expertise, authoritativeness, and trustworthiness inherently positions itself as a leader in the market. Clients today seek more than just machines—they seek partners in progress who will empower them with tools that define the future of their enterprises. A manufacturer who delivers on these four pillars not only meets but exceeds industry expectations, paving the way for sustainable growth and enduring influence in the steel pipe manufacturing realm.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!