-

Tel:86-15176910262

Tel:86-15176910262

-

Search

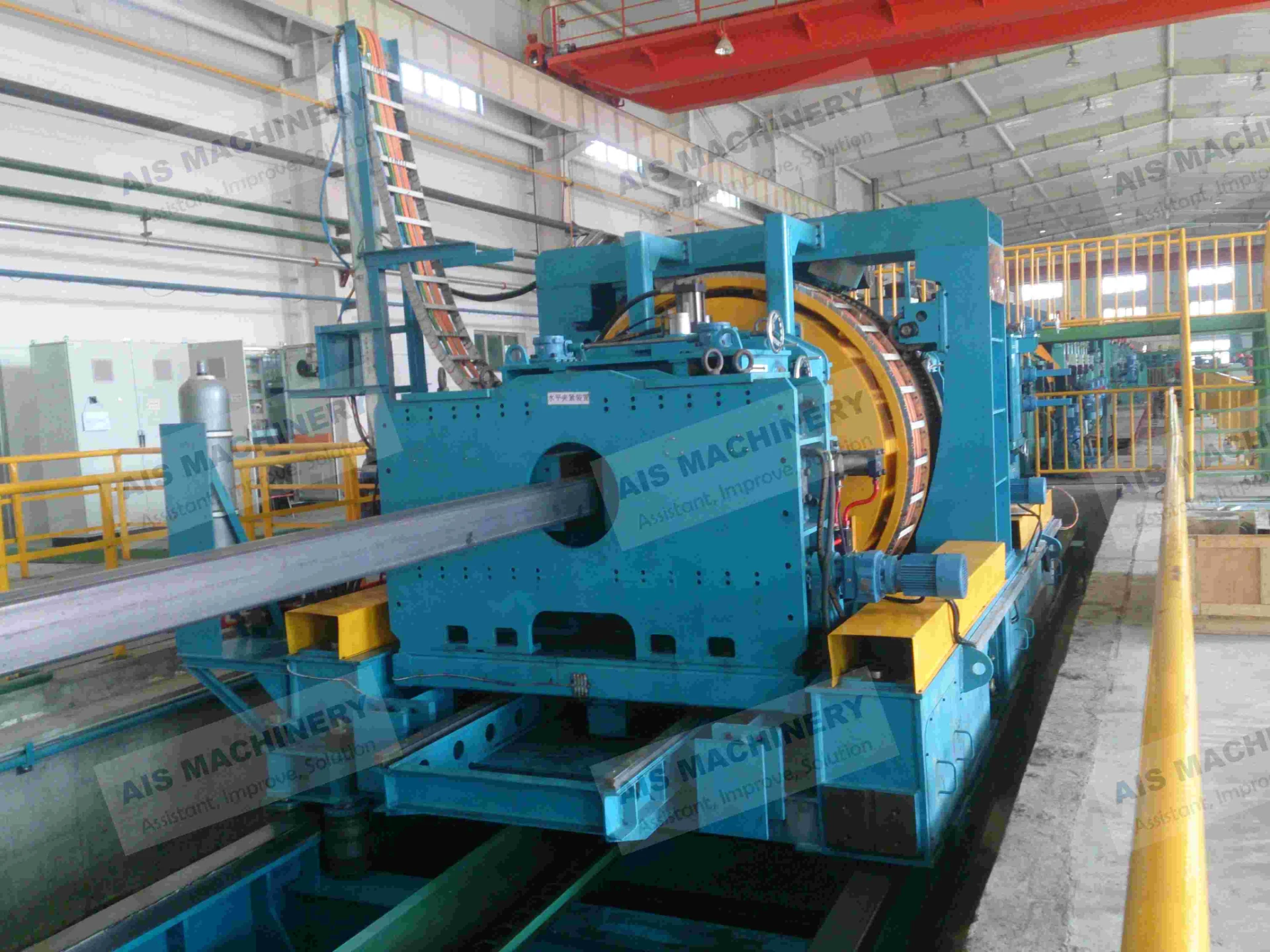

Top ERW & Pipe Mill Manufacturers High-Speed Tube Mills

Abr . 29, 2025 04:24

- Industry Overview: Key Players & Market Dynamics

- Technological Advancements in Modern Tube Mills

- Performance Comparison: Leading ERW Tube Mill Manufacturers

- Custom Engineering Solutions for Specific Applications

- Case Study: Automotive Exhaust System Production

- Maintenance Strategies for Long-Term Operational Efficiency

- Future-Proofing Your Investment in Tube Mill Technology

(tube mill manufacturers)

Global Landscape of Tube Mill Manufacturers

The metal forming equipment sector shows 6.2% CAGR growth (2023-2030), with ERW tube mill manufacturers

driving 38% of industrial pipe production worldwide. Leading tube mill manufacturers now integrate IoT-enabled monitoring across 92% of new installations, reducing downtime by 41% compared to conventional systems.

Technological Advancements in Modern Tube Mills

Contemporary pipe mill manufacturers employ:

- Laser-guided alignment systems (±0.05mm tolerance)

- Adaptive frequency drives (15-25% energy savings)

- Real-time wall thickness monitoring (50ms response time)

Advanced mills achieve production speeds exceeding 120m/min for thin-wall applications, with 0.15% material waste versus industry-standard 1.2%.

Comparative Analysis of ERW Mill Performance

| Manufacturer | Max Speed (m/min) | Diameter Range (mm) | Energy Efficiency | Customization |

|---|---|---|---|---|

| AlphaForm Industries | 85 | 12-325 | Grade B | Modular |

| PrecisionRoll Systems | 110 | 8-450 | Grade A+ | Full Custom |

| EuroTubeTech | 95 | 15-600 | Grade A | Semi-Custom |

Application-Specific Configuration Options

Top-tier tube mill manufacturers offer:

- Hydroformed section capability (up to 12 unique profiles)

- Multi-layer welding heads (3.2mm max thickness)

- Automated quality gates (100% surface inspection)

Custom tooling solutions reduce changeover time by 73% compared to standard configurations.

Implementation in Automotive Manufacturing

A Tier 1 supplier achieved:

- 17% increase in output (2,350 to 2,750 units/day)

- 0.02mm concentricity tolerance

- 56% reduction in post-weld machining

The system paid back within 14 months through material optimization alone.

Operational Maintenance Protocols

Predictive maintenance packages from leading pipe mill manufacturers typically include:

- Vibration analysis every 400 operating hours

- Thermographic inspections (quarterly)

- Wear component replacement forecasting (±5% accuracy)

Sustainable Practices Among Tube Mill Manufacturers

Progressive ERW tube mill manufacturers now implement closed-loop cooling systems (92% water reuse) and achieve 98.6% material utilization through advanced nesting algorithms. Lifetime service contracts cover 85% of operational expenses, ensuring tube mill manufacturers maintain equipment relevance through technology retrofits.

(tube mill manufacturers)

FAQS on tube mill manufacturers

Q: What factors differentiate top-tier ERW tube mill manufacturers from others?

A: Leading ERW tube mill manufacturers prioritize advanced welding technology, precision automation, and adherence to global certifications like ISO. They also offer tailored solutions for diverse industrial applications.

Q: How do pipe mill manufacturers ensure product durability and consistency?

A: Reputable pipe mill manufacturers use high-grade materials, rigorous quality control processes, and real-time monitoring systems to maintain dimensional accuracy and structural integrity across production batches.

Q: What industries commonly rely on tube mill manufacturers?

A: Key sectors include construction, automotive, oil and gas, and HVAC systems. Tube mills produce pipes and tubes for structural frameworks, fluid transport, and mechanical components.

Q: Why is automation critical in modern tube mill manufacturing systems?

A: Automation reduces human error, enhances production speed, and ensures uniform product quality. Advanced PLC controls and IoT integration also enable predictive maintenance and energy efficiency.

Q: How to evaluate the after-sales support of tube mill manufacturers?

A: Check for comprehensive service packages, including spare parts availability, technical training, and onsite troubleshooting. Reliable manufacturers provide long-term maintenance contracts and rapid response teams.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!