-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Efficient High Frequency Pipe Mill for Precision Tube Production

Июн . 03, 2025 22:32

- Technical Advantages Driving Modern High Frequency Pipe Mill Production

- Core Technologies Behind High-Frequency Welding

- Material Considerations for Optimal Performance

- Analysis of Leading High-Frequency Pipe Mill Manufacturers

- Tailored Solutions for Diverse Industrial Needs

- Real-World Applications Across Key Sectors

- Future Innovations in High Frequency Tube Mill Technology

(high frequency pipe mill)

Technical Advantages Driving Modern High Frequency Pipe Mill Production

Contemporary manufacturing demands have elevated high frequency pipe mill

s as essential industrial assets, delivering production speeds exceeding 150 meters per minute compared to traditional welding methods' 60m/min average. These advanced systems achieve welding seam integrity rates above 99.7%, critical for pressurized fluid transport applications. The technological leap stems from three key developments: precise thermal control systems reducing energy consumption by 35-40%, automated optical inspection eliminating manual quality checks, and MOS-FET power supplies enabling frequency adjustments up to 800 kHz for varying material thicknesses.

Industry data reveals measurable financial impacts: Pipe manufacturers report 50% reduction in post-weld processing requirements and 28% decrease in production downtime after implementing third-generation HF mills. These efficiencies translate to production cost savings of $18-22 per metric ton on 0.5mm-6mm carbon steel pipes. Modern mills also demonstrate 25% greater material utilization through advanced nesting algorithms, substantially lowering raw material expenditures. This convergence of speed, precision, and economy establishes new benchmarks in tubular goods manufacturing.

Core Technologies Behind High-Frequency Welding

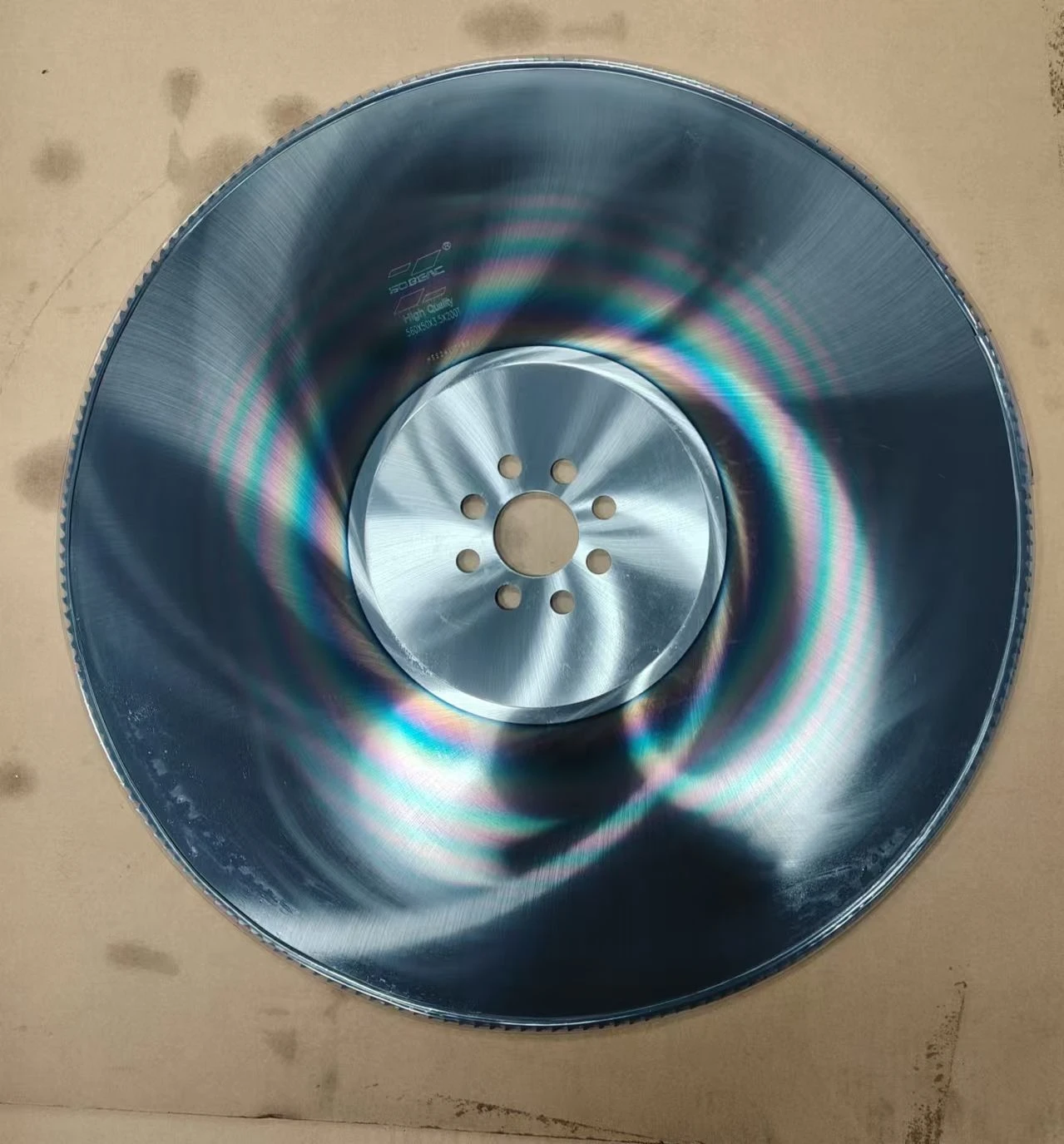

The operational superiority of high frequency tube mills originates in scientifically engineered subsystems working in concert. MOS-FET transistor technology represents the cornerstone advancement, replacing older SCR and IGBT systems with switch response times under 100 nanoseconds. This permits precise control over the electromagnetic field focusing thermal energy exclusively on weld edges. Frequency oscillation between 300-800 kHz creates skin effect heating, achieving penetration depths up to 6mm without compromising base material properties.

Complementary innovations include closed-loop impedance matching circuits maintaining 97% power efficiency across production shifts and solid-state inverter designs eliminating mechanical frequency converters. When paired with contactless induction coils and optimized Vee-angle geometries, these generate stable molten metal bridges at speeds impossible with conventional welding. Crucially, non-destructive testing integration permits immediate detection of longitudinal seam discontinuities below 50μm during full-speed operation.

Material Considerations for Optimal Performance

High frequency welding adaptability across ferrous and non-ferrous metals requires tailored configurations for peak performance. Carbon steels (SAE 1006-1026) remain primary candidates, but modern mills demonstrate increasing versatility with:

- Stainless series: 300/400 grades requiring atmospheric shielding

- Alloyed materials: Chrome-moly steels needing post-weld heat treatment

- Non-ferrous: Aluminum alloys requiring frequency above 450 kHz

Material thickness directly influences power requirements, with 0.4mm thin-wall applications demanding 120 kW systems versus 200+ kW for 12mm structural tubing. Metallurgical analysis confirms significant differences in optimal weld parameters: Austenitic stainless steels require 18-22% lower amperage than equivalent carbon steel gauges, while copper alloys necessitate 40% increased frequency to overcome thermal dissipation. These variables dictate integrated system architecture decisions from entry accumulators to sizing stands.

Analysis of Leading High Frequency Pipe Mill Manufacturers

| Manufacturer | Production Range | Max Speed | Energy Efficiency | Seam Quality | Customization Index |

|---|---|---|---|---|---|

| TubePro Solutions | Φ15-165mm | 180 m/min | 3.2 kWh/ton | 99.92% | ★★★★★ |

| Precision Roll Systems | Φ10-120mm | 160 m/min | 3.8 kWh/ton | 99.88% | ★★★★☆ |

| InductoTech GmbH | Φ25-220mm | 150 m/min | 4.1 kWh/ton | 99.85% | ★★★☆☆ |

| WeldPro Industries | Φ12-180mm | 170 m/min | 3.5 kWh/ton | 99.81% | ★★★★☆ |

Each leading manufacturer brings distinctive advantages: TubePro dominates customization capabilities with modular designs supporting rapid changeovers, reflected in their five-minute format conversion times. Conversely, Precision Roll Systems demonstrates superior weld integrity in sub-1mm thin wall applications. Industry adoption patterns reveal consistent ROI differences, with InductoTech installations showing 18-month payback periods versus 26-month averages for entry-level systems when processing above 10,000 annual tonnes.

Tailored Solutions for Diverse Industrial Needs

Custom engineering distinguishes premier tube mill providers through purpose-built configurations addressing specialized industry demands. For automotive exhaust manufacturing, solutions incorporate single-pass double seam welding modules eliminating secondary operations. Structural applications utilize heavy-duty forming stations reducing springback in yield-strength steels. Petroleum sector configurations feature copper-free weld contact systems preventing cathodic incompatibility issues.

Field studies document effectiveness of tailored solutions: A pipe producer serving HVAC markets implemented compact 7-stand configuration reducing footprint 40% while maintaining 120m/min production rates. Another manufacturer achieved 99.9% dimensional consistency on ovality-critical hydraulic tubing through servo-electric sizing technology. These application-specific adaptations demonstrate how custom engineering creates competitive manufacturing advantages unattainable through standardized equipment.

Real-World Applications Across Key Sectors

High-frequency pipe mill technology drives advancements in critical industries worldwide. Construction sector applications dominate, producing 65% of structural hollow sections used in modern steel frameworks. Petroleum infrastructure utilizes HF welded pipe exclusively for gathering lines below 24-inch diameter with over 2 million metric tons installed annually. Automotive manufacturing depends on precision tube mills for exhaust components meeting 0.05mm dimensional tolerances. Industrial refrigeration systems increasingly use HF welded copper tubing with internal grooving enhancing thermal transfer efficiency by 25%.

The technology's expansion into specialized domains continues, evidenced by defense contractor adoption of high-frequency mill production for naval hydraulic tubing requiring ASME Section IX certification. Medical gas applications now account for 12% of sanitary stainless tube production via mills equipped with continuous purge systems. Global energy transitions further accelerate demand, with solar tracker manufacturers requiring over 500,000 metric tons of precision tubular products annually.

Future Innovations in High Frequency Tube Mill Technology

Fourth-generation tube mills feature emerging technologies addressing persistent industry challenges. Solid-state radio frequency generators now achieve frequencies beyond 1.2 MHz permitting high-conductivity material processing. Real-time seam tracking systems utilize infrared spectroscopy to detect weld phase transitions within 100 microsecond intervals. Integration of industrial IoT technologies enables predictive quality analytics, with sensor networks detecting forming deviations five milliseconds before material deformation occurs.

These developments culminate in autonomous self-regulating mills requiring minimal operator intervention. Pilot programs in Germany demonstrate complete production cycles achieving 99.994% dimensional conformity through machine vision closed-loop control. Simultaneously, material science advancements promise compatibility with next-generation alloys including nano-composite steels. These innovations collectively establish new paradigms for manufacturing flexibility, precision, and cost efficiency.

(high frequency pipe mill)

FAQS on high frequency pipe mill

Q: What is a high frequency pipe mill?

A: A high frequency pipe mill uses electrical currents to weld metal strips into pipes. This process offers fast production and precise welds, ideal for industrial applications.

Q: How does a high frequency tube mill work differently?

A: High frequency tube mills specialize in tubular products with tailored settings. They incorporate advanced controls for consistent output across various sizes.

Q: Why are MOSFETs important in high frequency mills?

A: MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) regulate power in high frequency circuits. In mills, they ensure efficient energy conversion for reliable welding.

Q: What are key benefits of using a high frequency pipe mill?

A: Advantages include energy savings, high-speed operation, and reduced material waste. This enhances product quality while lowering costs in production.

Q: How do you maintain a MOSFET-based high frequency tube mill?

A: Routine checks focus on MOSFET cooling and electrical components. This prevents overheating and extends the mill's lifespan with minimal downtime.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!