Описание продукта

1. Introduction

The Pipe Straightener Machine is an essential auxiliary component of a welded pipe production line. It is primarily used to straighten pipes after welding and sizing, ensuring that they meet required linearity and geometric standards. Typically placed downstream in the production line, it corrects bending or deformation caused during forming, welding, cooling, or transportation processes.

2. Function in Welded Pipe Production

-

Straightens formed welded pipes – Corrects axial bending, waviness, and ovality issues.

-

Improves dimensional accuracy – Ensures straightness for further processing such as cutting, punching, coating, or bundling.

-

Reduces defect rate – Enhances product consistency and reduces scrap.

-

Supports automation – Compatible with high-speed continuous lines, improving overall production efficiency.

3. Technical Specification Table

| Item |

Specification Range |

| Applicable Pipe OD |

Φ15mm – Φ120mm (customizable) |

| Pipe Wall Thickness |

0.5mm – 6.0mm |

| Number of Rollers |

5+3, 6+4 configurations (top + bottom) |

| Roller Material |

Alloy steel / carbide-treated |

| Straightening Speed |

10–60 m/min (adjustable via inverter) |

| Motor Power |

5.5 – 15 kW |

| Adjustment Method |

Manual / Electric / Hydraulic |

| Control System |

PLC + HMI (optional) |

| Pipe Type |

Welded pipes (carbon steel, stainless steel, etc.) |

4. Main Components

-

Machine Base – Welded steel frame supporting the system;

-

Straightening Rollers – Core units arranged in top and bottom sets for pipe correction;

-

Drive System – Motor + gearbox + chains/gears to rotate the rollers;

-

Adjustment Mechanism – To adjust roller gap and angle for different pipe sizes;

-

Guide Device – Ensures precise entry of the pipe into the rollers;

-

Control Panel – For setting speed, pressure, and roller position;

-

Safety Devices – Emergency stop buttons, protective covers, etc.

5. Operation Procedure

-

Preparation:

-

Startup Settings:

-

Feeding and Straightening:

-

Output and Inspection:

6. Maintenance

Daily Maintenance:

-

Inspect rollers for wear or damage;

-

Check for loose bolts or fasteners;

-

Clean machine surfaces to prevent jamming;

-

Lubricate moving parts (recommended daily).

Periodic Maintenance (monthly or quarterly):

-

Calibrate roller angles and spacing;

-

Check electrical components for loose connections or overheating;

-

Maintain electric/hydraulic adjustment systems (if equipped);

-

Replace excessively worn parts.

Precautions:

-

Do not process non-standard or oversized pipes;

-

Avoid long idle running;

-

Stop the machine immediately if abnormal noise, vibration, or jamming occurs.

-

-

-

- 1. Coil car and Storage

- 2.Single And Double Heads Un-coiler & Hydraulic And Pneumatic Un-coiler

- 3.Peeler and hold down roll arm

- 4.Flattening Machine

- 5.Automatic and Semi Auto Shearer & Butt Welder

- 6.Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

-

- 1. Машина вихретокового контроля

- 2. Seam annealing machine

- 3. Straightener machine

- 4. Chamfer and end facer machine

- 5. Hydro Tester machine

- 6. Threading machine

- 7. Painting and oil machine

- 8. Automatic bundle and package machine

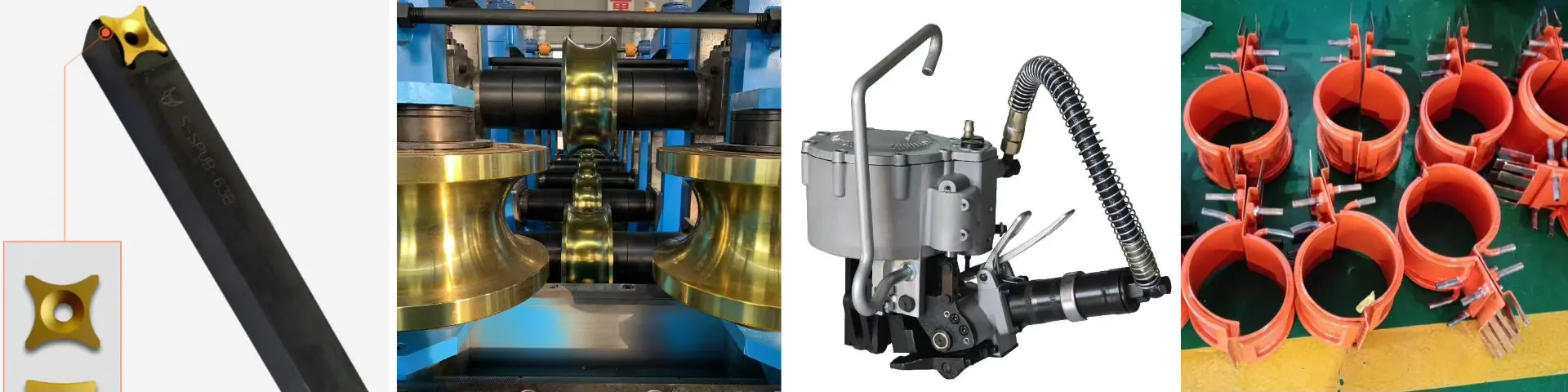

Spare Parts and Consumble Parts

-

- 1. Rollers, Moulds, Dies, D2,D3 material to choose

- 2. Ferrite, Impeder, Fiberglass tube

- 3. HSS saw blades, TCT Saw blades, Friction saw blades

- 4. OD burr remove inserts, ID burr remover inserts

- 5. HF welder Induction Coil and other HF welder spare parts

- 6. Copper tube for induction Coil, PTFE pipe for Induction Coil

- 7. Mosfet, Boards

- 8. Steel pipe Strapping machine

- 9. Zinc Spray Machine, Zinc wire, Zinc spray gun

- Почему стоит выбрать нас?

-

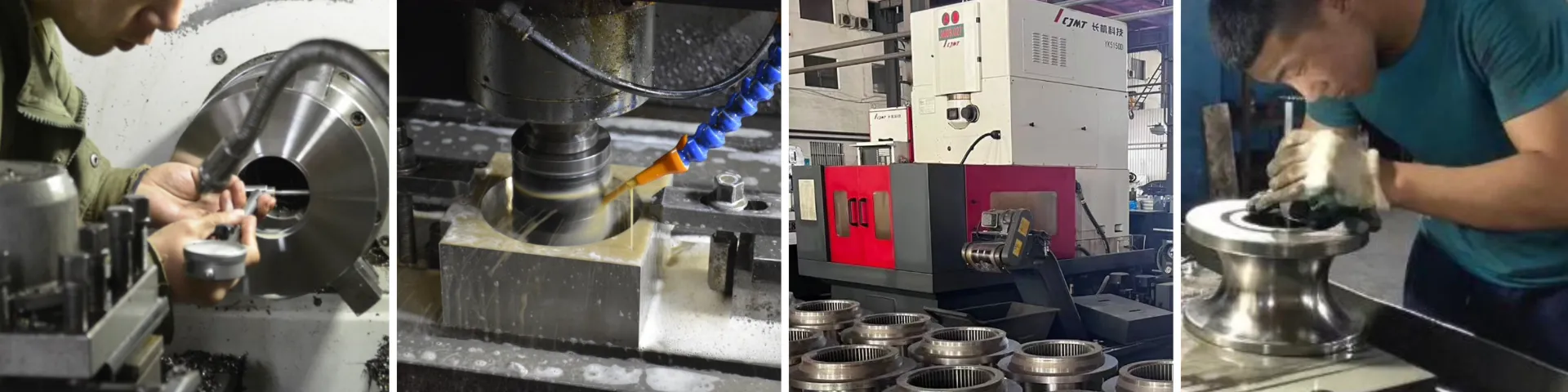

1.Leading Technology, Reliable Quality, Excellent Service! Оптимизированный дизайн, выбор высококачественных материалов! Гарантия процесса термообработки!

-

2.Spiral bevel gear, drum gear coupling and carburization. Закалка зубьев шестерен. Приводная система стабильна, эффективна и удобна в использовании с низким уровнем шума.

-

3.High precision wear resisting and Long life of toolings. Все токарные станки, шпоночные пазы позиционируются и фрезеруются с помощью ЧПУ.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Послепродажное обслуживание

- 1.Machine test running videos will supply to customer before shipment.

- 2.Online techenical support WHOLE LIFT FREE.

- 3.Professional engineers team to install the machine, train your employee well.

- 4.One year warranty and life-long technical support.

- 5,24 часа на ответ инженера.

- 6.Ваши деловые отношения с нами будут конфиденциальны для любых третьих лиц.

- 7. We welcome customers to visit our factory anytime.

Тел:86-15176910262

Тел:86-15176910262