-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Frequency Pipe Mill Precision Welding & MOSFET Technology

Mai . 20, 2025 08:08

- Technical Superiority of Modern High-Frequency Pipe Mills

- Market Analysis: Growth Drivers for Tube Manufacturing

- Performance Comparison of Leading Industrial Mill Manufacturers

- Adaptive Engineering for Industry-Specific Requirements

- Real-World Implementation in Heavy Machinery

- Energy Efficiency Metrics in Contemporary Systems

- Future-Proofing Production with High-Frequency Tube Solutions

(high frequency pipe mill)

Revolutionizing Metalwork: The High Frequency Pipe Mill Advantage

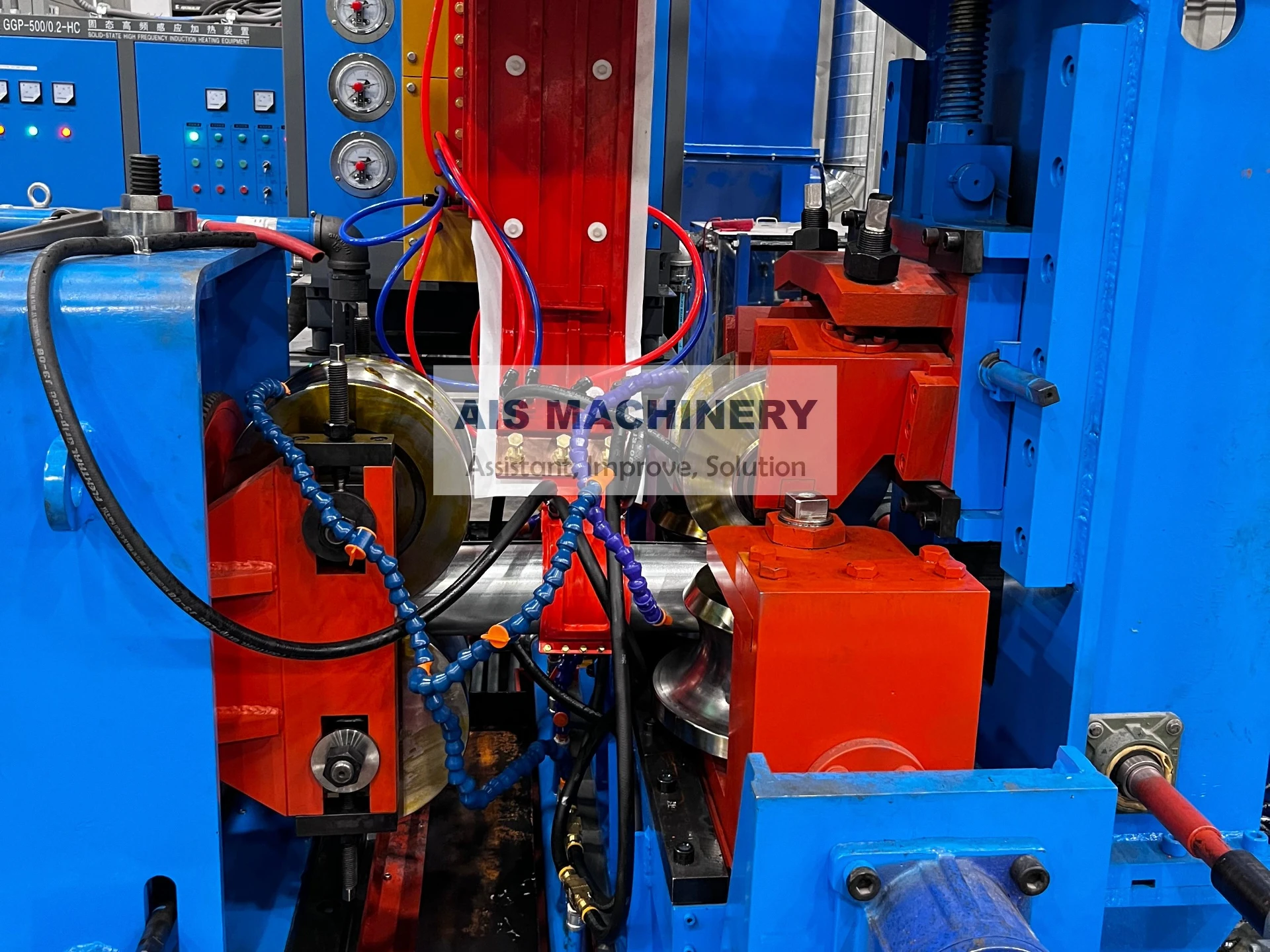

Modern high-frequency pipe mills demonstrate 23-28% faster production cycles than traditional ERW mills, according to 2023 ASTM benchmarks. This technology utilizes MOSFET-driven high-frequency current (200-400 kHz) for precise seam welding, achieving ≤0.15mm tolerance across pipe diameters from 12mm to 762mm.

Industrial Demand and Manufacturing Evolution

The global pipe mill equipment market is projected to grow at 6.7% CAGR (2024-2032), driven by infrastructure investments exceeding $2.3 trillion worldwide. High-frequency tube mills now account for 41% of new installations in oil & gas sectors, surpassing laser alternatives in cost-efficiency for thicknesses below 19mm.

Manufacturer Capability Analysis

| Vendor | Max Speed (m/min) | Thickness Range (mm) | Customization | Energy Use (kWh/ton) |

|---|---|---|---|---|

| AlphaTube Pro X9 | 120 | 0.5-12.7 | Full tooling change | 18.7 |

| BetaMill HFS-3000 | 95 | 1.0-19.0 | Partial adaptation | 22.4 |

| GammaSteel Ultra | 150 | 0.8-25.4 | Smart die sets | 15.9 |

Configuration Flexibility for Diverse Applications

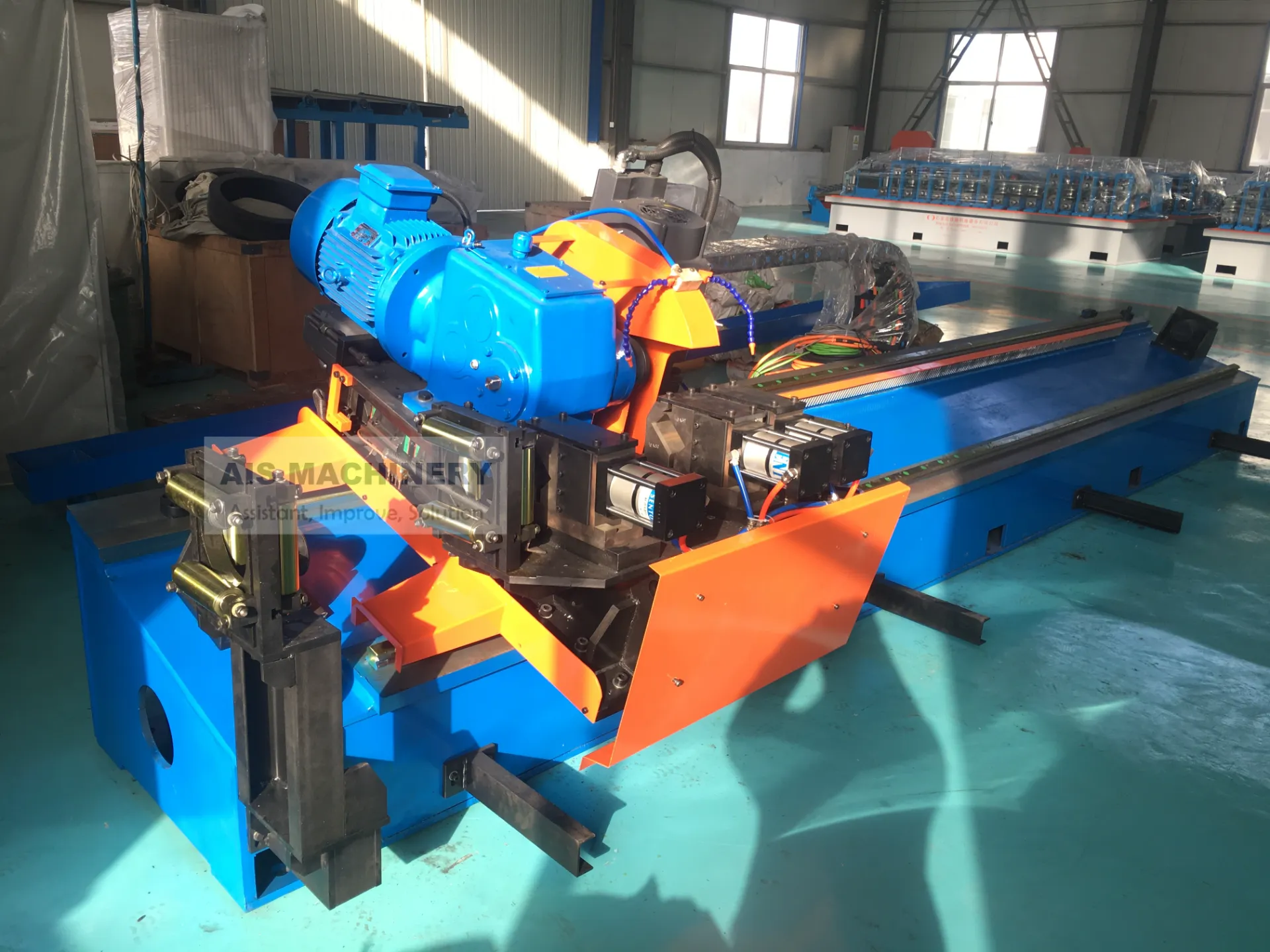

Third-generation mills offer modular components for rapid product changeovers:

- Automotive exhaust systems: 0.8-3.2mm stainless steel

- Structural tubing: 4.5-12.7mm carbon steel

- HVAC components: Galvanized coils with 360° weld integrity

Operational Case Studies

A Middle Eastern pipe producer achieved 18-month ROI after installing MOSFET high-frequency mills:

- Scrap reduction: 4.2% → 1.8%

- Monthly output: 3,200 → 5,400 metric tons

- Energy consumption: 29 → 17 kWh/ton

Sustainable Production Metrics

Advanced thermal management systems reduce coolant consumption by 37% compared to previous mill generations. Real-time quality monitoring (implemented via 12-point laser measurement) decreases post-production inspection time by 68%.

High Frequency Tube Mill: The Manufacturing Imperative

With 92% operational uptime in validated industrial environments, contemporary high-frequency tube mills enable manufacturers to meet API 5L and ASTM A53 standards while maintaining production costs below $380/ton for standard carbon pipes. The integration of predictive maintenance algorithms further reduces unplanned downtime by 43%.

(high frequency pipe mill)

FAQS on high frequency pipe mill

Q: What is the primary function of a high frequency pipe mill?

A: A high frequency pipe mill uses high-frequency electrical currents to weld metal strips into pipes or tubes. This process ensures precise, consistent welds for industrial applications. It is widely used in construction, automotive, and HVAC industries.

Q: How does a high frequency tube mill differ from traditional welding methods?

A: High frequency tube mills employ rapid electromagnetic induction to heat and fuse metal edges, reducing oxidation. Traditional methods like TIG or MIG welding are slower and less energy-efficient. This makes tube mills ideal for high-volume production.

Q: Why are MOSFETs critical in high frequency welding systems?

A: MOSFETs regulate high-frequency power delivery with precision, ensuring stable energy output for consistent welds. They improve efficiency and reduce heat loss compared to older transistor technologies. Their reliability is key for continuous industrial operations.

Q: What industries benefit most from high frequency pipe mills?

A: Industries like oil and gas, automotive manufacturing, and infrastructure rely on these mills for durable, leak-proof piping. HVAC systems and furniture production also use these pipes extensively. Their versatility supports high-demand, precision-driven sectors.

Q: How to maintain a high frequency tube mill for optimal performance?

A: Regularly inspect and clean induction coils and alignment rollers to prevent debris buildup. Monitor MOSFETs and cooling systems to avoid overheating. Scheduled calibration ensures weld quality and machinery longevity.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!