-

Tel:86-15176910262

Tel:86-15176910262

-

Suchen

Steel Pipe Making Machine for Sale: How to Choose the Right Equipment and Manufacturer

Mai . 12, 2025 14:50

If you’re looking to produce steel pipes in-house, investing in a steel pipe making machine is a smart move. Whether you're expanding production capacity or launching a new fabrication line, having your own equipment offers better control over quality, cost, and lead times.

But not all machines are equal. There are different models, automation levels, and price points—each with its pros and cons. This guide will walk you through everything you need to know about steel pipe making machines for sale, how they work, what they cost, and how to choose the right manufacturer.

What Is a Steel Pipe Making Machine?

A steel pipe making machine—also called a tube mill or metal pipe making machine—forms flat steel strips into round, square, or rectangular pipes through a continuous roll-forming and welding process. It's commonly used to manufacture pipes for construction, automotive, furniture, agriculture, oil and gas, and general industrial use.

The main sections of a pipe making line include:

Uncoiler – Holds and releases steel coils.

Leveling & Shearing – Flattens the strip and trims edges.

Forming Mill – Shapes the strip into a round tube using rollers.

High-Frequency Welding – Fuses the edges of the pipe together.

Sizing & Shaping – Adjusts diameter and thickness as needed.

Cutting Unit – Cuts the pipe to specified lengths.

Run-Out Table – Collects and stacks finished pipes.

Types of Steel Pipe Making Machines

1. High-Frequency Welded Pipe Machine

The most widely used model for carbon and galvanized steel.

Fast, reliable, and ideal for round and square tubes.

Welds pipe with strong, clean seams.

2. Stainless Steel Pipe Making Machine

Built for corrosion-resistant materials.

Often includes argon welding systems or TIG welding.

Used in food-grade and medical industries.

3. Square and Rectangular Pipe Machine

Designed to directly produce square or rectangular shapes.

Avoids additional shaping after round pipe production.

4. Heavy-Duty Structural Pipe Machines

For large-diameter or thick-wall pipes used in infrastructure and oil & gas.

Why Buy a Steel Pipe Making Machine?

Lower Production Costs – Eliminate outsourcing and gain control over pricing.

Custom Pipe Dimensions – Easily switch between sizes with changeable roller sets.

Scalable Output – Choose capacity according to your business growth stage.

Quick ROI – Once operational, the machine can pay for itself through high-volume production.

Competitive Advantage – Meet custom orders faster and offer better pricing to clients.

How to Choose a Steel Pipe Making Machine Manufacturer

When looking for a Stahlrohrherstellungsmaschine zu verkaufen, don’t just compare specs—look at the manufacturer’s reputation, service quality, and customization capabilities.

Experience and Industry Focus

Choose manufacturers with a strong track record in your specific application (e.g., stainless steel vs. structural pipes).

Customization

Need to make multiple pipe sizes? Ask if the supplier can design a machine with interchangeable roller sets or quick-change systems.

Automation

Modern machines often include PLC control, servo feeding, and automatic cutting, which reduce labor and improve consistency.

After-Sales Service

Make sure the manufacturer provides installation guidance, operator training, spare parts, and technical support.

Material Quality

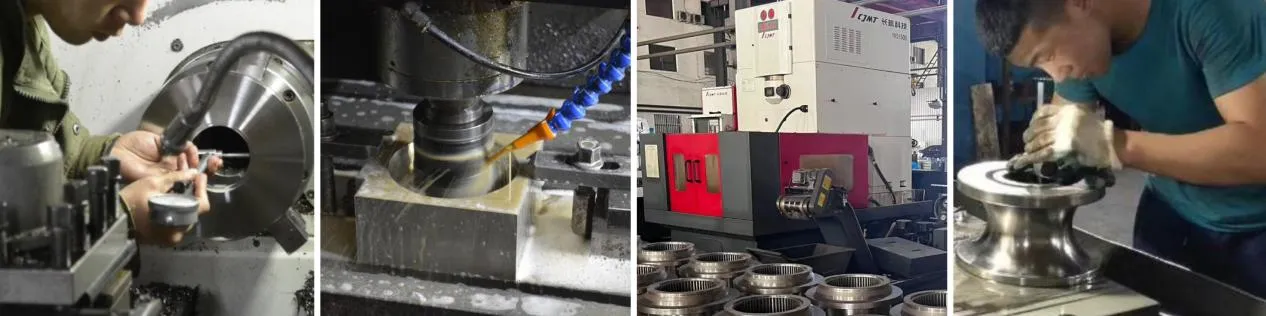

Check if key components (rollers, shafts, bearings) use hardened or alloy steel for durability.

Steel Pipe Manufacturing Machine Price

Prices vary widely based on machine type, output capacity, automation level, and materials processed.

Here’s a general price range:

|

Machine Type |

Estimated Price (USD) |

|

Entry-Level Manual Pipe Mill |

$20,000 – $50,000 |

|

Semi-Automatic HF Welded Machine |

$60,000 – $120,000 |

|

Fully Automatic Production Line |

$130,000 – $300,000+ |

|

Stainless Steel Pipe Making Machine |

$100,000 – $250,000 |

|

Large Diameter Structural Mill |

$200,000 – $500,000+ |

These are estimates—final pricing depends on size range (e.g., 16mm to 89mm or 89mm to 219mm), pipe thickness, speed, and added features.

Key Tips Before Buying

Ask for client references or visit an operating line if possible.

Review the electrical standards—machines should match your local voltage/frequency.

Inquire about tool change times if you’ll produce different pipe sizes.

Request a full list of spare parts and recommended maintenance schedules.

If you're shipping internationally, check packaging, insurance, and installation options.

Investing in a steel pipe making machine can transform your business. It puts control back in your hands—over quality, cost, and delivery. Whether you need high-speed output or flexibility for custom orders, the right machine and a reliable manufacturer make all the difference.

Compare your options carefully. Look beyond just price—factor in durability, automation, service, and long-term return. With a quality steel pipe manufacturing machine, you're not just buying equipment—you're investing in scalable production power.

Steel Pipe Making Machine FAQs

1. What materials can I process with a pipe making machine?

Most machines handle carbon steel, galvanized steel, and stainless steel. Some models can also process aluminum or copper.

2. How long does installation take?

Basic lines can be set up in 2–3 weeks. More advanced systems with automation may require up to 6 weeks.

3. Can one machine make multiple pipe sizes?

Yes, with interchangeable rollers and tooling. Many systems support a size range (e.g., 16–89mm).

4. How often do I need to maintain the machine?

Regular maintenance (weekly/monthly) includes roller lubrication, alignment checks, welding system calibration, and cleaning.

5. What is the lead time when ordering a new machine?

Most manufacturers quote 45–90 days for production and shipping, depending on customization needs.

Verwandte Produkte

Verwandte Nachrichten

Eine Nachricht senden

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!