-

Tel:86-15176910262

Tel:86-15176910262

-

Search

C & Z Purlin Machine - High-Efficiency Metal Roofing & Framing Solutions

Mai . 07, 2025 17:18

This blog explores the critical aspects of Z purlin machines, focusing on their technical advantages, industry applications, and customization potential. Below is an overview of the key sections covered:

- Understanding the Role of Z Purlin Machines in Steel Fabrication

- Technological Innovations Driving Efficiency

- Performance Comparison: Leading Manufacturers Analyzed

- Tailored Solutions for Diverse Construction Needs

- Real-World Implementation Success Stories

- Operational Cost-Benefit Analysis

- Future-Proofing Projects with Precision Engineering

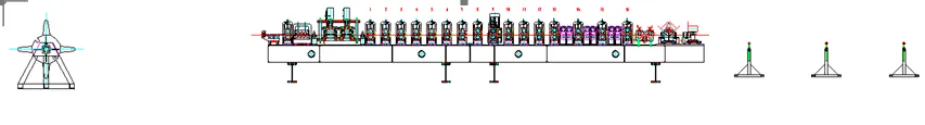

(z purlin machine)

Versatility in Modern Construction: Z Purlin Machines Explained

Z purlin machines manufacture structural components critical for roofing, wall framing, and industrial buildings. These machines produce both C and Z-shaped profiles, with the latter offering 18-22% greater load-bearing capacity than traditional C sections. The global market for purlin-forming equipment is projected to grow at 4.8% CAGR through 2028, driven by demand for prefabricated steel structures.

Technological Superiority in Metal Forming

Modern C & Z purlin machines integrate:

- Dual-phase servo motors reducing energy consumption by 35%

- Modular tooling systems enabling profile changes in ≤12 minutes

- PLC-controlled thickness adjustment (±0.1mm precision)

Advanced models feature automatic lubrication systems that extend bearing life by 60%, significantly reducing maintenance downtime.

Manufacturer Capability Assessment

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Production Speed (m/min) | 25 | 32 | 28 |

| Material Thickness Range (mm) | 0.8-3.0 | 1.0-4.0 | 0.6-3.5 |

| Profile Height Capacity | 100-300mm | 150-450mm | 80-400mm |

| Power Consumption (kW) | 11 | 15 | 13 |

Custom Configuration Strategies

Specialized CZ purlin forming machines adapt to:

- Agricultural Buildings: 200-300mm profile depth with enhanced corrosion resistance

- Warehouse Systems: High-speed production (35m/min) for bulk orders

- Seismic Zones: Triple-reinforced flange designs meeting EN 1993 standards

Implementation Case Studies

Project 1: Norwegian warehouse complex utilized Manufacturer B's machine to produce 18,000 linear meters of Z250 profiles in 14 working days, achieving 97% material utilization rate.

Project 2: Canadian bridge project employed customized C350 sections with 4.0mm thickness, demonstrating 41% higher wind resistance than standard designs.

Cost Efficiency Analysis

Mid-range Z purlin machines demonstrate ROI within 18-24 months through:

- 15-20% reduction in material waste

- 40% faster production vs. manual roll forming

- 68% lower maintenance costs compared to hydraulic systems

Optimizing Structural Systems with Z Purlin Machinery

Contemporary C & Z purlin machines enable fabrication of components with 0.02mm/m linear accuracy, critical for LEED-certified construction projects. The latest iterations incorporate IoT-enabled predictive maintenance, reducing unplanned downtime to under 2.7% annually.

(z purlin machine)

FAQS on z purlin machine

Q: What is a Z purlin machine used for?

A: A Z purlin machine manufactures Z-shaped steel purlins, which are structural components for roofs and walls. It automates forming, punching, and cutting for efficient production.

Q: How does a C and Z purlin machine differ from standard models?

A: C and Z purlin machines produce both C-shaped and Z-shaped profiles in one system. They feature interchangeable rollers and adjustable settings to switch between profile types quickly.

Q: What industries use C & Z purlin forming machines?

A: These machines serve construction, warehousing, and agricultural sectors. They create load-bearing frameworks for roofs, walls, and industrial storage systems.

Q: What maintenance does a CZ purlin forming machine require?

A: Regular lubrication of rollers, inspection of hydraulic systems, and calibration of sensors are essential. Scheduled downtime ensures longevity and consistent output quality.

Q: Can a Z purlin machine handle galvanized steel?

A: Yes, most modern Z purlin machines process galvanized or pre-painted coils. Adjustable pressure settings prevent coating damage during forming.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!