-

Tel:86-15176910262

Tel:86-15176910262

-

Search

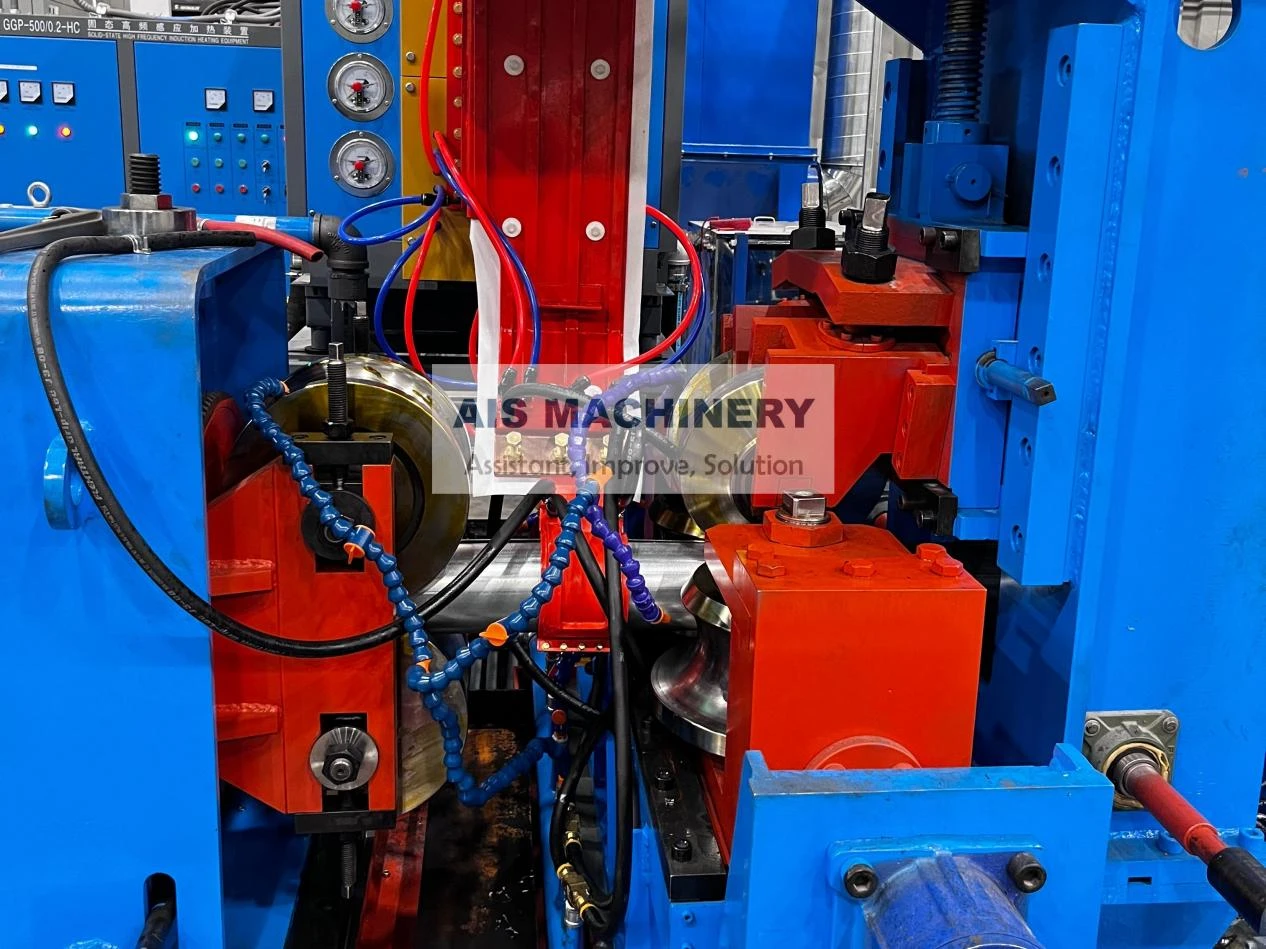

Tube Mill Equipment & Metal Fabrication Solutions Premium Machinery

May . 24, 2025 06:18

- Industry Overview & Market Data Insights

- Technological Advancements in Tube Mill Systems

- Competitive Analysis of Leading Manufacturers

- Customization Strategies for Diverse Applications

- Case Studies: Operational Success Stories

- Maintenance and Spare Parts Optimization

- Future Trends in Tube Mill Equipment Solutions

(tube mill equipment)

Driving Efficiency with Advanced Tube Mill Equipment

The global tube mill equipment

market is projected to grow at a 5.8% CAGR through 2030, fueled by demand from construction and automotive sectors. Modern systems integrate servo-controlled cutting and automated material handling, reducing production downtime by up to 40% compared to conventional models. A 2023 industry survey revealed that 78% of manufacturers prioritize energy-efficient motors when upgrading tube forming lines.

Engineering Excellence in Metal Processing

Third-generation tube mills now feature:

- Laser-guided alignment systems (±0.1mm precision)

- Cloud-based performance monitoring

- Hybrid drive systems reducing energy consumption by 30%

These innovations enable production speeds exceeding 120 meters/minute for stainless steel tubing, with wall thickness consistency maintained within 5% variance.

Manufacturer Performance Benchmarking

| Parameter | Company A | Company B | Company C |

|---|---|---|---|

| Max Speed (m/min) | 150 | 135 | 142 |

| Motor Type | Permanent Magnet | Induction | Hybrid |

| Customization Options | 15 | 9 | 12 |

| Energy Consumption (kW/h) | 18.7 | 23.4 | 20.1 |

Application-Specific Configuration Models

Modular designs allow rapid reconfiguration for different production scenarios:

- Automotive: High-speed cutting modules (cycle time: 8s/tube)

- Construction: Heavy-wall forming stations (up to 25mm thickness)

- Energy: Corrosion-resistant material handling systems

Pre-engineered kits reduce installation time by 35% while maintaining ISO 9013 dimensional tolerances.

Real-World Implementation Results

A recent automotive parts supplier achieved:

- 19% material waste reduction

- 22% increase in daily output

- 14-month ROI on equipment upgrade

Post-installation analysis showed 93% operational availability during peak production periods.

Lifecycle Management Solutions

Predictive maintenance systems utilizing IoT sensors decreased unplanned downtime by 62% across 47 installations. Inventory optimization algorithms reduced spare parts stockholding costs by $18/m² monthly.

Tube Mill Equipment: Shaping Industrial Progress

With 68% of manufacturers planning capacity expansions by 2025, next-generation tube mill systems are evolving with AI-powered quality control and hydrogen-compatible components. Our field tests demonstrate that optimized cut-to-length equipment can achieve 99.2% material utilization rates in high-volume operations.

(tube mill equipment)

FAQS on tube mill equipment

Q: What maintenance practices are essential for tube mill equipment?

A: Regular lubrication, inspection of rollers and welders, and alignment checks ensure optimal performance. Scheduled downtime for part replacements and software updates is also critical.

Q: How does cut-to-length equipment improve tube production efficiency?

A: It ensures precise material sizing, reduces waste, and integrates seamlessly with tube mills for continuous processing. Automated systems further minimize manual intervention.

Q: What auxiliary equipment is critical for tube mill operations?

A: Decoilers, straighteners, and hydraulic systems are vital. Spare parts like blades, bearings, and sensors also ensure minimal downtime during maintenance.

Q: How to troubleshoot common issues in tube mill equipment?

A: Check for misaligned rollers, worn welding tips, or calibration errors. Review equipment manuals and consult suppliers for specialized spare parts if needed.

Q: When should spare parts in tube mills be replaced proactively?

A: Replace high-wear components like blades and seals based on usage hours or manufacturer guidelines. Monitoring vibration and output quality helps predict failures early.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!