The processing of small diameter square tubes is generally to forming from round to square, that is, before the strip is welded, it is a round tube, and it is rolled into a square tube at the sizing part.

This equipment adopts the advanced direct square technology, which starts rolling into a square shape when the steel strip begins to forming. This advanced technology can help customers save at least 5% of the strip cost.

Direct square roll forming equipment does not need to change the tooling molds when producing square tubes and rectangular tubes of different sizes. The production of steel tubes of different sizes uses a set of molds. This item alone can help customers save at least 50% of the mold cost.

In addition, this technology can not only help customers save mold costs, but also can automatically adjust the mold by pressing a button when producing tubes of different sizes, saving customers at least 3 labor costs.

Direct square can produce square tubes with different diameters. The diameter range of the tube produced by this equipment is 100x100mm to 300x300mm.

List of Equipment and Scope of Supply

|

Equipment

|

Quantity

|

Note

|

|

Entry Section

▪Coil skid

▪Coil car

▪Uncoiler, Coil opener with hold down roll

▪Pinch roll with centering device (Seven roll Flattener)

▪ Automatic Shear & welder

▪Horizontal strip accumulator

|

2No.

1No.

1No.

1No.

1No.

1No.

|

Supplier

|

|

Mill section

▪Forming mill

|

1set

|

Supplier

|

|

Welding section

▪Seam guide roll stand, squeeze roll stand

▪Solid state H.F. induction welder GGp800KW

▪Outside bead scraping device

▪Water Cooling trough

|

1No.

1No.

1No.

1No.

|

Supplier

|

|

Sizing section

▪Sizing roll stand

▪Turk’s head stand

|

1Set.

1Set

|

Supplier

|

|

Exit section

▪Milling saw

▪Driven roller run out table ,Inspection table & Collectors

|

1Set.

1No.

|

Supplier

|

|

Finishing section

▪Straigtener machine

▪One head Chamfer machine

▪One head Hydro tester machine

▪Automatic package machine

|

1Set.

1Set

1Set

1Set

|

online

|

|

Spare

▪offline shaft system for round to round roller change

▪offline stands several for square to round roller change

▪additional rollers to produce 80X80 direct square

|

1Set

1Set

1Set

|

|

Design of the proposed line is based on following specification:

Raw Material Specification

|

Material to be processed

|

Low Carbon steel & Galvanized steel, Q195-Q355

|

|

Material

|

δb≤500Mpa, δs≤345Mpa

|

|

Coil OD

|

Max 2200mm

|

|

Coil ID

|

610mm(depend on customer order)

|

|

Coil Weight

|

Max 30,000 kg

|

|

Strip Width

|

Min 400mm, Max 1200mm

|

|

Strip Thickness

|

Min 3.0 Max 12.0 mm

|

Production Range

|

Type of production

|

▪Square and Rectangular Hollow Sections

|

|

Square Hollow Section

|

Min 100x100mm, Max 300x300mm

|

|

Rectangular Hollow Section

|

Min 80x120mm, Max 400x200mm

|

|

Square Tube Thickness

|

Min 3.0mm, Max 12mm

|

|

Tube Cut Length

|

Min 6 meter, Max 12meter

|

|

Tube Standard

|

Dimensionally as per any relevant international standard

|

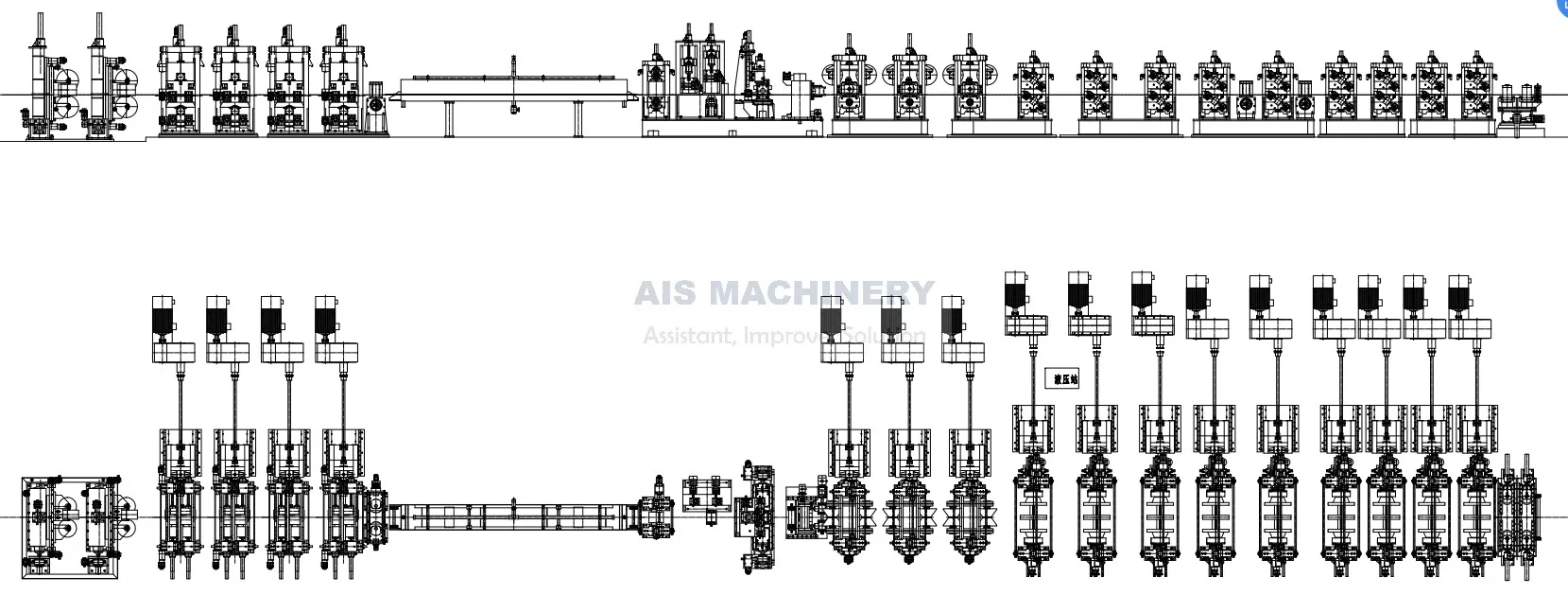

The Technical Flow of the Production Line

{Steel Tape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→Spiral accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Milling saw →→ Run-out table →→Straingtener machine →→Chamfer machine →→Hydro tester machine →→automatic package machine

OUR SERVICE

Why Choose Us?

Leading Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Heat treatment process guarantee!

Spiral bevel gear, drum gear coupling and carburization.

Gear teeth quenching.

Driven system stable, efficient and wearable with lower noise.

High precision wear resisting and Long life of rollers.

All the machine Lathes, Key Grooves are positioned and Milled by CNC.

Our Service

Pre-sale service

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factor

After-sales service

1.We will delivery the machine and provide the documents on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions, Our fast and professional aftersales service engineer team will go to your factory to install the machine, give you the operating manual, And train your employee until they can operate the machine well.

3.We provide one year warranty and life-long technical support.

4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

5 .24 hours for engineer response.

6.Your business relationship with us will be confidential to any third party.

Quality Control

We have the single quality department, that make sure the material of the raw materials is good, and ensure the machine running smoothly.

Tel:86-15176910262

Tel:86-15176910262