The processing of small diameter square tubes is generally to forming from round to square, that is, before the strip is welded, it is a round tube, and it is rolled into a square tube at the sizing part.

This equipment adopts the advanced direct square technology, which starts rolling into a square shape when the steel strip begins to forming. This advanced technology can help customers save at least 5% of the strip cost.

Direct square roll forming equipment does not need to change the tooling molds when producing square tubes and rectangular tubes of different sizes. The production of steel tubes of different sizes uses a set of molds. This item alone can help customers save at least 50% of the mold cost.

In addition, this technology can not only help customers save mold costs, but also can automatically adjust the mold by pressing a button when producing tubes of different sizes, saving customers at least 3 labor costs.

Direct square can produce square tubes with different diameters. The diameter range of the tube produced by this equipment is 100x100mm to 300x300mm.

List of Equipment and Scope of Supply

|

Uskunalar

|

Miqdori

|

Eslatma

|

|

Kirish bo'limi

▪ Bobinli skidka

▪ Bobinli avtomobil

▪Uncoiler, ushlagichli rulonli ochuvchi

▪ Markazlash moslamasi bilan chimchilash rulosi (etti rulonli tekislagich)

▪ Automatic Shear & welder

▪Gorizontal chiziqli akkumulyator

|

2No.

1No.

1No.

1No.

1No.

1No.

|

Yetkazib beruvchi

|

|

Mill section

▪Forming mill

|

1 to'plam

|

Yetkazib beruvchi

|

|

Welding section

▪Dikişni yo'naltiruvchi rulonli stend, siqish rulonli stend

▪Solid state H.F. induction welder GGp800KW

▪Tashqi munchoqlarni qirib tashlash moslamasi

▪Water Cooling trough

|

1No.

1No.

1No.

1No.

|

Yetkazib beruvchi

|

|

O'lchov bo'limi

▪O'lchamli rulonli stend

▪Turk’s head stand

|

1 to'plam.

1 to'plam

|

Yetkazib beruvchi

|

|

Exit section

▪ Frezeli arra

▪Yo'zg'aluvchan rolikli stol, Tekshirish stoli va Kollektorlar

|

1 to'plam.

1No.

|

Yetkazib beruvchi

|

|

Finishing section

▪Straigtener mashinasi

▪Bir boshli chamfer mashinasi

▪Bir boshli gidro tester mashinasi

▪Avtomatik qadoqlash mashinasi

|

1 to'plam.

1 to'plam

1 to'plam

1 to'plam

|

onlayn

|

|

Zaxira

▪ Rolikni dumaloqdan dumaloqgacha almashtirish uchun oflayn mil tizimi

▪ oflayn rolikni kvadratdan dumaloqga almashtirish uchun bir nechta stendlar

▪80X80 to'g'ridan-to'g'ri kvadrat ishlab chiqarish uchun qo'shimcha roliklar

|

1 to'plam

1 to'plam

1 to'plam

|

|

Taklif etilayotgan liniyaning dizayni quyidagi spetsifikatsiyalarga asoslanadi:

Xom ashyo spetsifikatsiyasi

|

Ishlov beriladigan material

|

Low Carbon steel & Galvanized steel, Q195-Q355

|

|

Material

|

δb≤500Mpa, δs≤345Mpa

|

|

Bobin OD

|

Maksimal 2200 mm

|

|

Bobin identifikatori

|

610 mm (mijoz buyurtmasiga bog'liq)

|

|

Bobinning og'irligi

|

Max 30,000 kg

|

|

Chiziq kengligi

|

Min 400mm, Max 1200mm

|

|

Chiziq qalinligi

|

Min 3.0 Max 12.0 mm

|

Ishlab chiqarish diapazoni

|

Ishlab chiqarish turi

|

▪Kvadrat va to'rtburchaklar bo'shliq bo'laklar

|

|

Kvadrat ichi bo'sh qism

|

Min 100x100mm, Max 300x300mm

|

|

To'rtburchaklar ichi bo'sh qism

|

Min 80x120mm, Max 400x200mm

|

|

Square Tube Thickness

|

Min 3.0mm, Max 12mm

|

|

Quvurni kesish uzunligi

|

Min 6 meter, Max 12meter

|

|

Standart quvur

|

Har qanday tegishli xalqaro standartga muvofiq o'lchovli

|

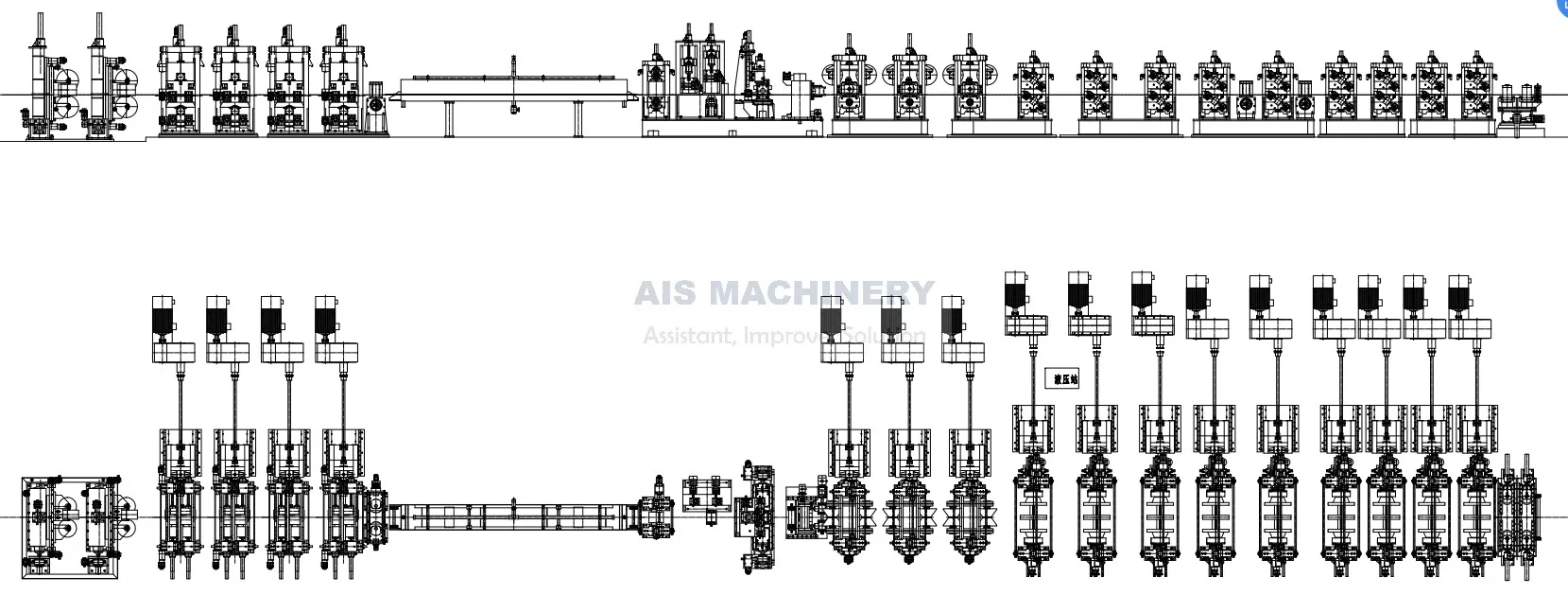

The Technical Flow of the Production Line

{Steel Tape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→Spiral accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Milling saw →→ Run-out table →→Straingtener machine →→Chamfer machine →→Hydro tester machine →→automatic package machine

BIZNING XIZMAT

Nima uchun bizni tanlaysiz?

Etakchi texnologiya, ishonchli sifat, zo'r xizmat!

Optimallashtirilgan dizayn, yuqori sifatli materialni tanlang!

Issiqlik bilan ishlov berish jarayoni kafolati!

Spiral konusli tishli, barabanli tishli ulanish va karbürizatsiya.

Tishli tishlarni o'chirish.

Boshqariladigan tizim barqaror, samarali va past shovqin bilan taqiladigan.

Yuqori aniqlikdagi aşınmaya bardoshli va rulonlarning uzoq umri.

Barcha dastgoh stanoklari, kalit yivlari CNC tomonidan joylashtirilgan va frezalangan.

Bizning xizmatimiz

Sotishdan oldingi xizmat

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factor

Sotishdan keyingi xizmat

1.Mashinani tezda olishingizga ishonch hosil qilish uchun biz mashinani yetkazib beramiz va hujjatlarni o'z vaqtida taqdim etamiz

2. Tayyorgarlik shartlarini tugatgandan so'ng, bizning tez va professional sotuvdan keyingi xizmat ko'rsatish bo'yicha muhandis jamoamiz mashinani o'rnatish uchun zavodingizga boradi, sizga foydalanish qo'llanmasini beradi va ishchingizni mashinani yaxshi boshqara olmaguncha o'rgatadi.

3.Biz bir yillik kafolat va umrbod texnik yordamni taqdim etamiz.

4. Yaxshi o'qitilgan va tajribali xodimlar sizning barcha so'rovlaringizga ingliz va xitoy tillarida javob berishlari kerak

Muhandis javobi uchun 5 .24 soat.

6.Biz bilan bo'lgan biznes munosabatlaringiz har qanday uchinchi tomon uchun maxfiy bo'ladi.

Sifat nazorati

Bizda yagona sifat bo'limi mavjud bo'lib, u xomashyo materialining yaxshi ekanligiga ishonch hosil qiladi va mashinaning muammosiz ishlashini ta'minlaydi.

Tel: 86-15176910262

Tel: 86-15176910262