The processing of small diameter square tubes is generally to forming from round to square, that is, before the strip is welded, it is a round tube, and it is rolled into a square tube at the sizing part.

This equipment adopts the advanced direct square technology, which starts rolling into a square shape when the steel strip begins to forming. This advanced technology can help customers save at least 5% of the strip cost.

Direct square roll forming equipment does not need to change the tooling molds when producing square tubes and rectangular tubes of different sizes. The production of steel tubes of different sizes uses a set of molds. This item alone can help customers save at least 50% of the mold cost.

In addition, this technology can not only help customers save mold costs, but also can automatically adjust the mold by pressing a button when producing tubes of different sizes, saving customers at least 3 labor costs.

Direct square can produce square tubes with different diameters. The diameter range of the tube produced by this equipment is 100x100mm to 300x300mm.

List of Equipment and Scope of Supply

|

Apparatus

|

quantitas

|

Nota

|

|

Viscus Sectionis

Coil LABOR

Coil car

Uncoiler, Coil opener in volumine deorsum tenere

▪ Pinch volvunt centrum fabrica (Septem volumine adulatorem)

▪ Automatic Shear & welder

horizontalis habena accumulator

|

2No.

1No.

1No.

1No.

1No.

1No.

|

Supplier

|

|

Mill section

▪Forming mill

|

1set

|

Supplier

|

|

Welding section

Seam dux volumine sto, premere volumine stand

▪Solid state H.F. induction welder GGp800KW

Extra caput rasurae fabrica

▪Water Cooling trough

|

1No.

1No.

1No.

1No.

|

Supplier

|

|

inspectionem sectionis

-Sizing sto volumine

▪Turk’s head stand

|

1Set.

1Set

|

Supplier

|

|

Exit section

Milling vidit

Coegi cylindro currere de mensa, inspiciendi mensam & collectores

|

1Set.

1No.

|

Supplier

|

|

Finishing section

Straigtener apparatus

Unum caput machina Chamfer

Unum caput Hydro robustum machina

Automatic sarcina apparatus

|

1Set.

1Set

1Set

1Set

|

online

|

|

Parce

-offline hastile ratio ad circum ad per cylindro mutatio

-offline stat pro pluribus quadrata rotundis cylindro mutatio

-Additional scutulis ad producendum 80X80 recta quadrata

|

1Set

1Set

1Set

|

|

Designatio lineae propositae sequenti specificatione nititur:

Rudis Material Specification

|

Materia ut processionaliter

|

Low Carbon steel & Galvanized steel, Q195-Q355

|

|

Materia

|

δb≤500Mpa, δs≤345Mpa

|

|

Coil OD

|

Max 2200mm

|

|

Coil ID

|

610mm (Lorem ordine depend)

|

|

Coil Pondus

|

Max 30,000 kg

|

|

Latitudo habena

|

Min 400mm, Max 1200mm

|

|

Crassitudo habena

|

Min 3.0 Max 12.0 mm

|

Productio Range

|

Genus productionis

|

Quadratum et rectangulum cavum Sectiones

|

|

Quadratus cavum sectionem

|

Min 100x100mm, Max 300x300mm

|

|

Rectangulare cavum sectionis

|

Min 80x120mm, Max 400x200mm

|

|

Square Tube Thickness

|

Min 3.0mm, Max 12mm

|

|

Tubus Cut Longitudo

|

Min 6 meter, Max 12meter

|

|

Tube Standard

|

Dimensionally ac per aliquem pertinet vexillum internationale

|

The Technical Flow of the Production Line

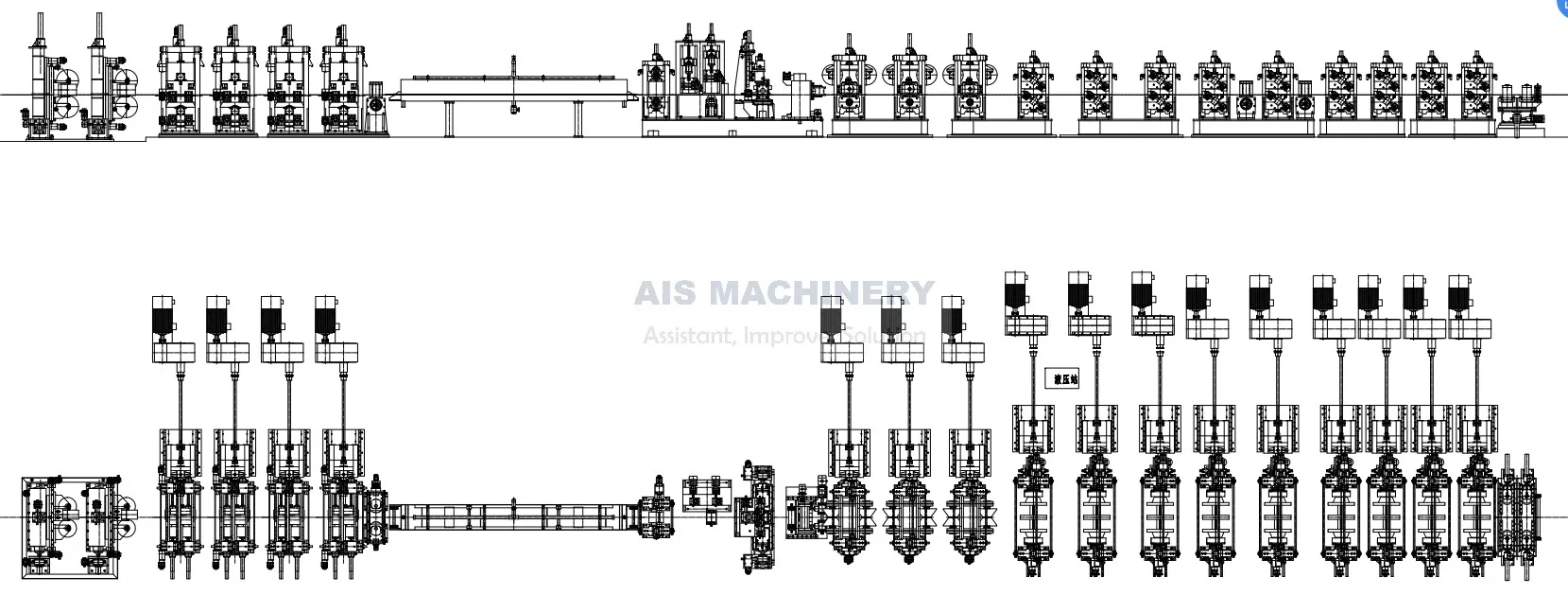

{Steel Tape}→→ Double-head un-coiler →→Strip-head Cutter and welder→→Spiral accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Milling saw →→ Run-out table →→Straingtener machine →→Chamfer machine →→Hydro tester machine →→automatic package machine

OPERA NOSTRA

Quid nos elige?

Ducens Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Caloris curatio processus spondet!

Calces cochleae revellere, orum calces copulatio et carburization.

Dentium calces exstingui.

Ratio acti stabilis, efficax et infatigabilis cum sonitu inferiori.

Summa subtilitate gerunt resistendo et longam tribulis vitam.

Tota machina Lathes, sulci Clavis a CNC cincta et molita sunt.

Our Service

Pre-venditionis officium

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factor

Post-Sales ministerium

1. Nos machinam trademus et documenta in tempore praebebunt ut machinam celeriter efficere possis

2. Praeparatio condiciones cum consummaveris, Ieiunium et professio nostra postsales servitii fectum ibit ad officinam tuam ut machinam instituat, manualem operantem tibi tribuat, et operarium tuum exerceat donec machinam bene operari possint.

3. Nos unum annum warantum et diuturnum technicum subsidium praebent.

4.Bene peritus & peritus baculus respondeat omnibus tuis quaestionibus Anglice et Sinice

5 .24 horae ad fectum responsum.

6. Negotium tuum cum nobis communicatio alicui tertiae parti secretior erit.

Qualitas Imperium

Unicum qualitatem habemus, quae materiam rudium materiarum bonam fac, et machinam nonumyter curet.

Tel:86-15176910262

Tel:86-15176910262