-

Teléfono: 86-15176910262

Teléfono: 86-15176910262

-

Buscar

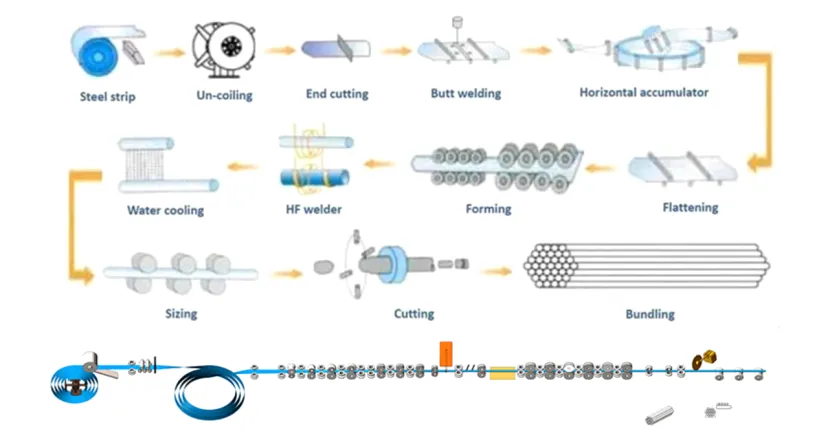

Diagrama de flujo del proceso de funcionamiento de la máquina para fabricar tubos ERW

Oct . 14, 2022 11:19

Straight seam welded pipes are widely used in various industries in life, such as solar pillar, scaffolding, furniture, and water gas transportation. But how are high-frequency straight seam welded pipes processed and produced? What is the production operation process of high-frequency straight seam welded pipe equipment? Now, I will explain it to you.

First, you need raw materials, hot-rolled, cold-rolled or galvanized steel strip coils. This type of steel strip coil is produced by a steel plant with an outer diameter of about 1.8 meters to 2 meters, a width of about 1.5 meters(or other sizes), and a single coil weight ranging from 10 to 30 tons.

Second, you need to slit the HR,CR,GI raw material steel strip coils to the appropriate width as needed. We call this step "slitting". For example, if you plan to produce a round tube with a diameter of 114mm, you need a steel strip with a width of 358mm (the actual width depends on the equipment). We need to slit the raw material steel strip coil (for example, a width of 1500mm) into strips with a width of 358mm. At this time, we need to use a SLITTING LINE. This equipment can slit the wide strip steel into the appropriate width we need, and then recoil it into small strip steel coils for easy use. If you are interested in SLITTING LINE, you can click the link below to view detailed parameters.

Third, Feeding the strip steel coil with a suitable width to the first equipment UCOILER/DECOILER of the CARBON STEEL ERW TUBE MILL. The Uncoiler opens the strip coil and puts the steel strip into the equipment in strip form.

If a roll of strip steel is used up, it is necessary to replace another roll of strip steel on the Uncoiler, and then weld the end of the previous roll of strip steel and the head of the second roll of strip steel with a SHEAR AND WELDING MACHINE, so that the equipment can work continuously and at high speed without stopping.

The strip enters the next equipment ACCUMULATOR LOOPER, which is used to store strip materials. The strip stored inside the looper can be used by subsequent equipment when the Uncoiler needs to change coils, ensuring the high-speed and uninterrupted production of the equipment.

Next, the strip enters the core equipment FORMING AND SIZING SECTION, which is the most important part of the equipment to squeeze the strip into a steel pipe through a set of dies and mould.

The steel strip is continuously welded by a high-frequency induction welding machine to become a steel pipe, and finally the steel pipe is cut into the length required by the customer by CUTOFF MACHINE.

Finally, the finished steel pipe is packaged and stored through CONVEYOR, RUN OUT TABLE, and PACKAGE.

The above description is the production process of ordinary steel pipes. If the steel pipe is used for API standard oil casing, natural gas transportation, etc., the steel pipe also needs to go through multiple finishing equipment inspections and tempering treatments. For details, please click the link below to get more support.

If you need more technical and product support, please send us an email.

Próximo

Próximo

This is the last article

Productos relacionados

Noticias relacionadas

Enviar un mensaje

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!