-

Tel:86-15176910262

Tel:86-15176910262

-

Search

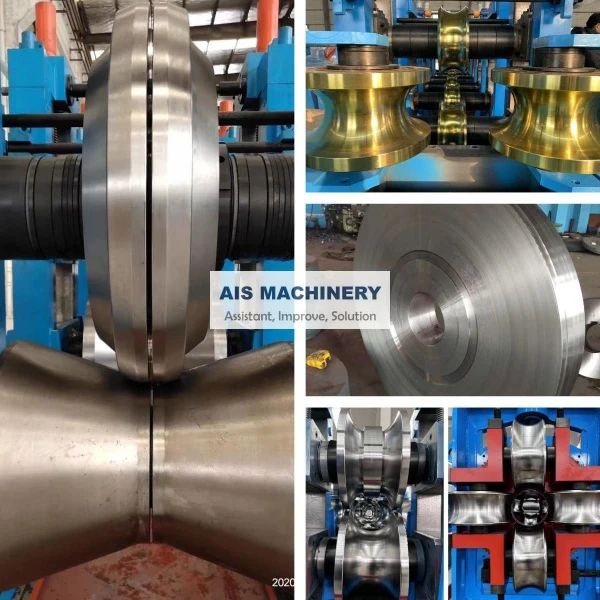

ERW Carbon Steel Tube Mill Machines Durable & Cost-Effective

Mai . 28, 2025 04:14

- Overview of Steel Tube Mill Technology and Market Trends

- Technical Advantages of Modern ERW Carbon Steel Tube Mills

- Performance Comparison: Leading Manufacturers in 2024

- Custom Solutions for Carbon Steel Tube Production Lines

- Case Study: ERW Mill Deployment in Automotive Manufacturing

- Maintenance Strategies for Long-Term Operational Efficiency

- Future Innovations in Carbon Steel Tube Mill Machinery

(steel tube mill)

Unlocking Precision with Advanced Steel Tube Mill Systems

The global demand for carbon steel tubes has risen by 12% annually since 2020, driven by infrastructure and energy projects. ERW (Electric Resistance Welding) technology now dominates 68% of welded tube production, with modern carbon steel tube mill

machines achieving dimensional tolerances of ±0.1mm. Leading manufacturers have reduced energy consumption by 25% through AI-powered optimization, while maintaining throughput speeds exceeding 120 meters/minute.

Technical Superiority in Tube Manufacturing

Contemporary ERW carbon steel tube mills integrate three critical innovations:

- Adaptive frequency converters reducing power waste by 18-22%

- Laser-guided seam tracking systems minimizing material loss

- Automated thickness control achieving 99.3% consistency

These advancements enable production of tubes meeting ASTM A500 Grade C standards with wall thickness uniformity within 0.05mm.

Manufacturer Benchmark Analysis

| Vendor | Max Speed (m/min) | Energy Use (kWh/t) | Tooling Life (hrs) | Price Range (USD) |

|---|---|---|---|---|

| TechTube Pro | 145 | 38 | 2,500 | 1.2M - 2.4M |

| MillMaster ERW | 132 | 42 | 1,800 | 950K - 1.8M |

| PrecisionRoll 7X | 155 | 35 | 3,000 | 1.5M - 3.1M |

Tailored Production Configurations

Customization options for carbon steel tube mill machine price optimization include:

- Modular designs allowing capacity upgrades from 5TPH to 22TPH

- Dual-material compatibility systems (carbon steel/stainless)

- Smart predictive maintenance interfaces

Operational data shows customized mills reduce changeover time by 40% compared to standard models.

Industrial Implementation Success

A Southeast Asian auto parts manufacturer achieved 91% yield improvement after installing a TechTube Pro ERW system, producing 8,500 metric tons/month of chassis components. Key metrics pre/post-implementation:

| Metric | Before | After |

|---|---|---|

| Monthly Output | 4,200t | 8,500t |

| Reject Rate | 5.7% | 1.2% |

| Energy Cost | $18.50/t | $14.80/t |

Sustaining Peak Operational Performance

Proactive maintenance protocols extend ERW mill service life by 30-35%:

- Real-time bearing temperature monitoring (±1°C accuracy)

- Automated lubrication cycles adjusted via production load

- Vibration analysis preventing 82% of unplanned downtime

Next-Gen ERW Carbon Steel Tube Mill Developments

Emerging technologies in ERW carbon steel tube mills include hydrogen-compatible welding systems for green manufacturing and machine learning algorithms that auto-correct strip alignment within 0.03mm precision. Industry forecasts predict 9.5% CAGR for smart tube mills through 2030, with embedded IoT sensors becoming standard across 92% of new installations by 2026.

(steel tube mill)

FAQS on steel tube mill

Q: What factors affect carbon steel tube mill machine price?

A: The price depends on production capacity, automation level, and material thickness range. Brand reputation and after-sales support also influence costs. Customization requirements may add to expenses.

Q: How does an ERW carbon steel tube mill differ from other mills?

A: ERW (Electric Resistance Welding) mills use high-frequency current to weld seams, ensuring precise joints. They're ideal for medium-to-high carbon steel production. This method reduces oxidation compared to traditional welding.

Q: What should I consider when choosing an ERW carbon steel tube mill manufacturer?

A: Prioritize manufacturers with ISO certification and proven industry experience. Evaluate their technical support and spare parts availability. Review client testimonials for reliability assessments.

Q: What quality control features do modern ERW tube mills include?

A: Advanced mills integrate real-time thickness gauges and weld seam detectors. Automated optical inspection systems ensure dimensional accuracy. Many include data logging for traceability and compliance.

Q: How often does an ERW carbon steel tube mill require maintenance?

A: Perform lubrication checks weekly and full system inspections monthly. Replace welding rollers every 3-6 months based on usage. Annual professional servicing maintains optimal performance.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!