The pneumatic steel pipe strapping machine is a purpose-built automation solution designed for bundling metal pipes efficiently and securely. It operates using compressed air as the driving force, enabling fast tensioning, sealing, and cutting of strapping materials. This equipment is ideal for final packaging sections on steel pipe production lines, offering safety, consistency, and high productivity.

Working Principle

Driven by compressed air, the strapping machine performs a series of precise mechanical actions. The typical process includes:

-

Positioning & Looping: The strapping band is manually or automatically looped around the pipe bundle.

-

Tensioning: A pneumatic tensioner pulls the band tight to the desired force.

-

Sealing: A locking mechanism secures the band using metal clips or fusion methods.

-

Cutting: The excess strap is trimmed by a pneumatic cutter.

-

Resetting: The system resets for the next strapping cycle.

The entire cycle is swift and operator-friendly, often integrated with pedal controls or a PLC interface for streamlined operations.

Key Technical Specifications (Customizable)

Applications

-

Steel pipe production (ERW, spiral, cold drawn, etc.)

-

Cold-formed steel packaging

-

Metal profiles and structural section bundling

-

Heavy-duty packaging for transport and storage

-

Industrial logistics and yard handling

Advantages

✅ Easy to Operate: Single-operator capable, saves labor

✅ Fast Bundling: Only 2–3 seconds per strap

✅ Flexible Adaptability: Works with various pipe sizes and strap widths

✅ Precise Tension Control: Adjustable to prevent surface damage

✅ Low Maintenance: Modular design allows quick part replacement

✅ Automation Ready: Easily integrates with packing lines or vision systems

-

Operation Notes

-

Ensure compressed air supply meets pressure and cleanliness requirements

-

Use strap and seals of compatible size and material for best results

-

Regularly inspect and lubricate tensioning wheels and cutting parts

-

Keep the strap path clean and clear of foreign materials

-

Drain air compressor moisture to prevent cylinder malfunction

-

Purchasing Recommendations

-

Choose model based on your pipe diameters and strap width

-

For high-speed production, opt for dual-channel or auto-positioning models

-

For large/heavy bundles, consider lifting assist arms for efficiency

-

For mass production, equip with auto strap dispensers and fault-prevention logic

-

Pourquoi nous choisir?

-

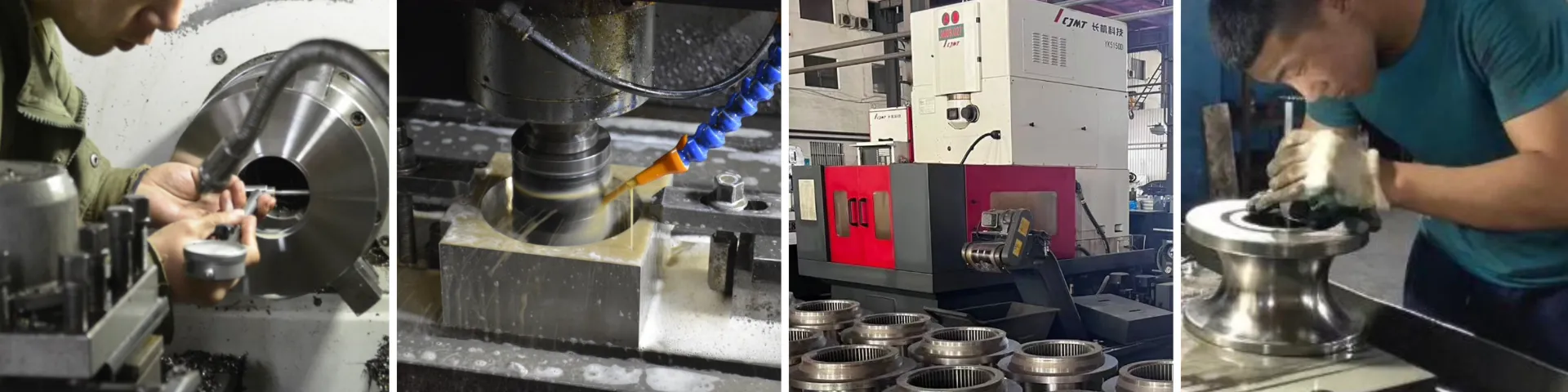

1.Leading Technology, Reliable Quality, Excellent Service! Optimized Design, High quality material select! Heat treatment process guarantee!

-

2.Spiral bevel gear, drum gear coupling and carburization. Gear teeth quenching. Driven system stable, efficient and wearable with lower noise.

-

3.High precision wear resisting and Long life of toolings. All the machine Lathes, Key Grooves are positioned and Milled by CNC.

-

4.Quality department make sure the material of the raw materials quality, and ensure the machine running perfect.

Tél. : 86-15176910262

Tél. : 86-15176910262