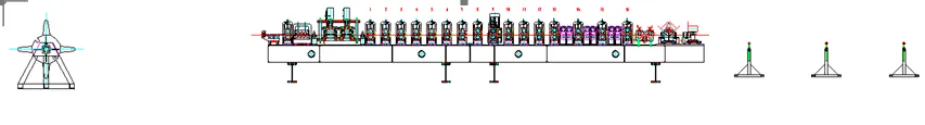

U-Channel Cold Roll Forming Machine Overview

The U-channel cold roll forming machine is a specialized production line designed to continuously shape steel strips into U-shaped profiles through a series of precision-formed rollers. By integrating advanced roll-forming technology with intelligent control systems, this equipment supports high-speed, automated production of U-channels widely used in structural, electrical, and industrial support applications.

-

| Raw Material: |

Hot-rolled or cold-rolled carbon steel, galvanized steel strips |

| Material Thickness Range: |

1.5 mm – 6.0 mm |

| Strip Width Range: |

80 mm – 500 mm |

| Forming Speed: |

8 – 20 meters per minute (customizable) |

| Number of Forming Stations: |

10–20 (depending on profile complexity) |

| Drive System: |

Gearbox drive or servo motor direct drive |

| Control System: |

Siemens PLC + touchscreen HMI |

| Punching Options: |

Servo punching / Hydraulic punching (optional) |

| Cutting System: |

Flying saw or hydraulic shear (optional) |

-

1.Apa kegunaan mesin roll forming?

Mesin cold roll forming digunakan dalam berbagai industri, termasuk konstruksi, otomotif, kedirgantaraan, dan manufaktur. Mesin ini sangat otomatis dan dapat menghasilkan produk berkualitas tinggi dengan kecepatan tinggi, sehingga menjadi pilihan populer untuk produksi massal.

2. BASIC DESIGN DATA

|

Channel Height:

|

40 mm – 150 mm

|

|

Flange Width:

|

20 mm – 80 mm

|

|

Edge Fold/Angle:

|

Customizable as needed

|

|

Length Accuracy:

|

±1.0 mm (depending on cut-off method)

|

3. Aliran teknis jalur produksi

{Steel Tape}→ Uncoiler →Strip-head Cutter and welder→Spiral accumulator→Forming section →Hole punching device→Hydraulic servo driven cutoff→→ Run-out table

4. Application Fields

1. U-channel profiles produced by this line are known for their strength and versatility. They are commonly used in:

-

2. Formwork support and scaffolding systems

-

3. Electrical racks, cable tray brackets

-

4. Tunnel and mining structural supports

-

5. Storage shelf beams and industrial framing

-

6. Automotive subframes and trailer components

5. Users Feedback

“Quick profile changeovers and high automation make this line ideal for multi-spec production.”

— Structural Parts Manufacturer

“The integrated punching and cutting unit significantly reduced labor and doubled our output efficiency.”

— Tunnel Support Supplier

“Finished U-channels have clean edges and consistent shapes—perfect for precision builds.”

— Racking Systems Producer

6. Usage Tips

-

Use high-quality, flat-edge steel strips to ensure smooth and accurate forming.

-

Clean and oil the rollers regularly to prevent corrosion and preserve shape precision.

-

For operations with frequent size changes, consider servo width adjustment and auto tool change systems.

-

Conduct routine checks on hydraulic oil, electrical connections, and sensor feedback to avoid unplanned downtime.

Telp:86-15176910262

Telp:86-15176910262