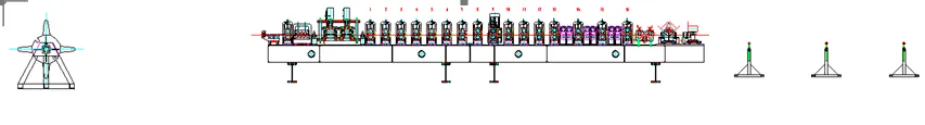

U-Channel Cold Roll Forming Machine Overview

The U-channel cold roll forming machine is a specialized production line designed to continuously shape steel strips into U-shaped profiles through a series of precision-formed rollers. By integrating advanced roll-forming technology with intelligent control systems, this equipment supports high-speed, automated production of U-channels widely used in structural, electrical, and industrial support applications.

-

| Raw Material: |

Hot-rolled or cold-rolled carbon steel, galvanized steel strips |

| Material Thickness Range: |

1.5 mm – 6.0 mm |

| Strip Width Range: |

80 mm – 500 mm |

| Forming Speed: |

8 – 20 meters per minute (customizable) |

| Number of Forming Stations: |

10–20 (depending on profile complexity) |

| Drive System: |

Gearbox drive or servo motor direct drive |

| Control System: |

Siemens PLC + touchscreen HMI |

| Punching Options: |

Servo punching / Hydraulic punching (optional) |

| Cutting System: |

Flying saw or hydraulic shear (optional) |

-

1. 롤포밍 머신은 무엇에 사용되나요?

콜드롤 성형 기계는 건설, 자동차, 항공우주 및 제조를 포함한 다양한 산업에서 사용됩니다. 이 기계는 고도로 자동화되어 있으며 높은 속도로 고품질 제품을 생산할 수 있어 대량 생산에 인기 있는 선택입니다.

2. BASIC DESIGN DATA

|

Channel Height:

|

40 mm – 150 mm

|

|

Flange Width:

|

20 mm – 80 mm

|

|

Edge Fold/Angle:

|

Customizable as needed

|

|

Length Accuracy:

|

±1.0 mm (depending on cut-off method)

|

3. 생산라인의 기술적 흐름

{Steel Tape}→ Uncoiler →Strip-head Cutter and welder→Spiral accumulator→Forming section →Hole punching device→Hydraulic servo driven cutoff→→ Run-out table

4. Application Fields

1. U-channel profiles produced by this line are known for their strength and versatility. They are commonly used in:

-

2. Formwork support and scaffolding systems

-

3. Electrical racks, cable tray brackets

-

4. Tunnel and mining structural supports

-

5. Storage shelf beams and industrial framing

-

6. Automotive subframes and trailer components

5. Users Feedback

“Quick profile changeovers and high automation make this line ideal for multi-spec production.”

— Structural Parts Manufacturer

“The integrated punching and cutting unit significantly reduced labor and doubled our output efficiency.”

— Tunnel Support Supplier

“Finished U-channels have clean edges and consistent shapes—perfect for precision builds.”

— Racking Systems Producer

6. Usage Tips

-

Use high-quality, flat-edge steel strips to ensure smooth and accurate forming.

-

Clean and oil the rollers regularly to prevent corrosion and preserve shape precision.

-

For operations with frequent size changes, consider servo width adjustment and auto tool change systems.

-

Conduct routine checks on hydraulic oil, electrical connections, and sensor feedback to avoid unplanned downtime.