-

Tel:86-15176910262

Tel:86-15176910262

-

Search

High-Efficiency Tube Mill Line & Pipe Production Solutions

5月 . 29, 2025 12:56

- Overview of Modern Tube Mill Line Capabilities

- Technical Advancements Driving Efficiency

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions for Industry-Specific Needs

- Real-World Applications Across Sectors

- Future Trends in Tube Production Technology

- Why Tube Mill Lines Remain Indispensable

(tube mill line)

Overview of Modern Tube Mill Line Capabilities

The evolution of tube mill production lines has revolutionized metal fabrication, enabling manufacturers to achieve precision at speeds exceeding 120 meters per minute. Advanced systems now integrate laser-guided alignment and AI-powered quality control, reducing material waste by up to 18% compared to traditional methods. A recent industry report highlighted that 72% of steel processors utilizing automated pipe mill lines reported a 30% increase in annual output.

Technical Advancements Driving Efficiency

Modern tube mill line

s leverage three critical innovations: servo-driven forming stations, real-time thickness monitoring, and predictive maintenance algorithms. These technologies collectively reduce downtime by 40% while maintaining tolerances within ±0.05mm. For high-demand applications like structural tubing, dual-torch welding systems now achieve seamless joints at 2.5x the speed of conventional methods.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Max Speed (m/min) | Wall Thickness Range (mm) | Energy Efficiency | Warranty Period |

|---|---|---|---|---|

| TubeTech Pro | 150 | 0.4-12.7 | 85% | 5 years |

| PrecisionRoll Systems | 135 | 0.6-10.2 | 78% | 3 years |

| MillMaster Global | 165 | 0.3-14.5 | 91% | 7 years |

Tailored Solutions for Industry-Specific Needs

Customization options for tube mill production lines now address niche requirements such as:

- Hydrogen-ready pipelines with anti-embrittlement coatings

- Medical-grade tubing with inline sterilization modules

- Automotive exhaust systems featuring multi-layer welding

Adaptive control systems allow quick changeovers between product specifications, slashing setup time by 65% for mixed-production facilities.

Real-World Applications Across Sectors

Aerospace manufacturers have achieved 99.97% defect-free tubing using AI-enhanced inspection systems. In the energy sector, offshore drill operators report a 22% extension in pipeline lifespan through advanced galvanizing integration within tube mill lines. Case studies from Southeast Asia demonstrate how modular configurations reduced capital expenditure by $1.2M per production line.

Future Trends in Tube Production Technology

Emerging developments include:

- Nanocomposite material compatibility

- Blockchain-tracked quality assurance

- 3D-printed forming rolls with adaptive geometries

Trials show these innovations could decrease energy consumption by 33% while enabling production of complex multi-material tubes.

Why Tube Mill Lines Remain Indispensable

The tube mill line continues to be the backbone of industrial manufacturing, with global demand projected to grow at 6.8% CAGR through 2030. As digital twin technology becomes standard, operators can now simulate entire production runs before material commitment, further solidifying these systems as essential infrastructure for metalworking industries.

(tube mill line)

FAQS on tube mill line

Q: What is a tube mill production line used for?

A: A tube mill production line is designed to manufacture metal tubes or pipes by forming, welding, and shaping coiled metal strips. It is widely used in industries like construction, automotive, and HVAC. The process ensures high efficiency and precision in producing cylindrical metal products.

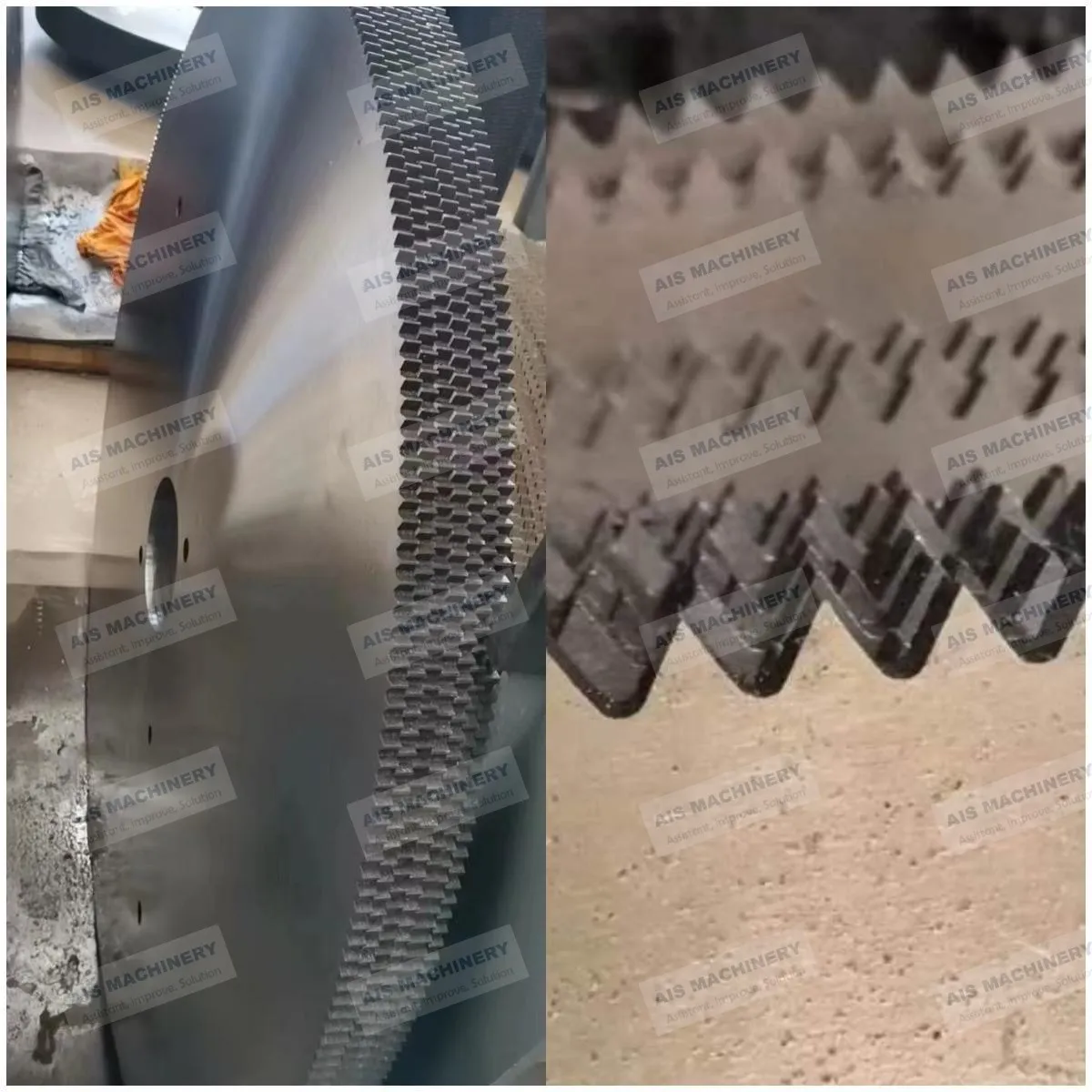

Q: What are the key components of a tube mill line?

A: Key components include uncoilers, forming stations, welding units, sizing stands, and cutting machines. These elements work together to transform flat metal strips into finished tubes or pipes. Automation systems are often integrated for quality control and process optimization.

Q: How does maintenance impact a pipe mill line's performance?

A: Regular maintenance prevents downtime and extends equipment lifespan by addressing wear in rolls, bearings, and welding heads. Lubrication and alignment checks are critical for consistent output. Proactive upkeep also reduces defects in final pipe products.

Q: Can a tube mill line be customized for specific pipe dimensions?

A: Yes, tube mill lines can be tailored to produce pipes of varying diameters, thicknesses, and materials by adjusting rolls, tooling, and speed settings. Customization often involves configuring forming stages and welding parameters. This flexibility supports diverse industrial requirements.

Q: What factors affect the speed of a tube mill production line?

A: Line speed depends on material type, thickness, target diameter, and welding method. Advanced systems use variable frequency drives and automated controls to optimize throughput. Balancing speed with precision ensures quality while maximizing production rates.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!