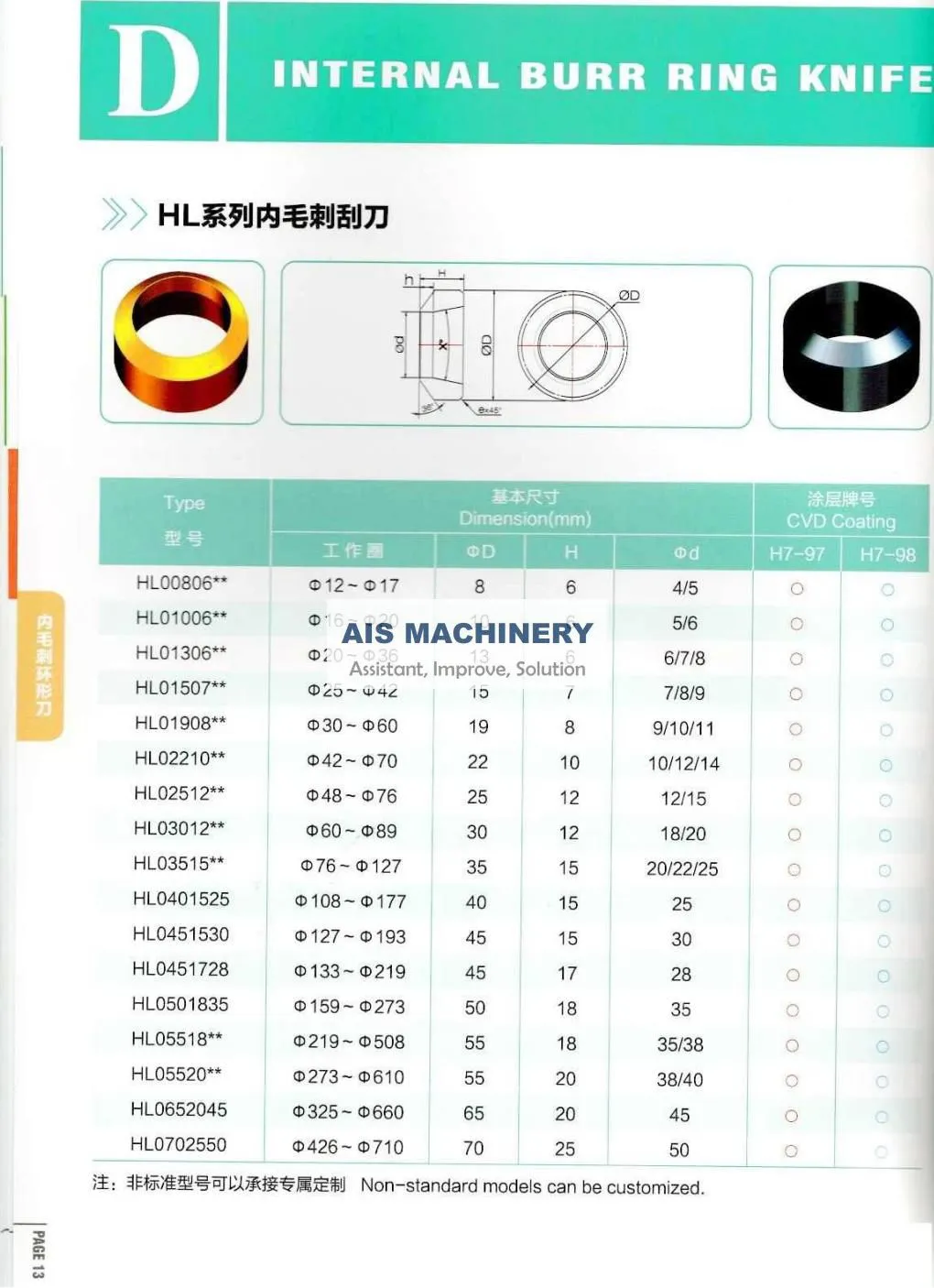

Inner Burr Removal Knife for ERW Tube Mills

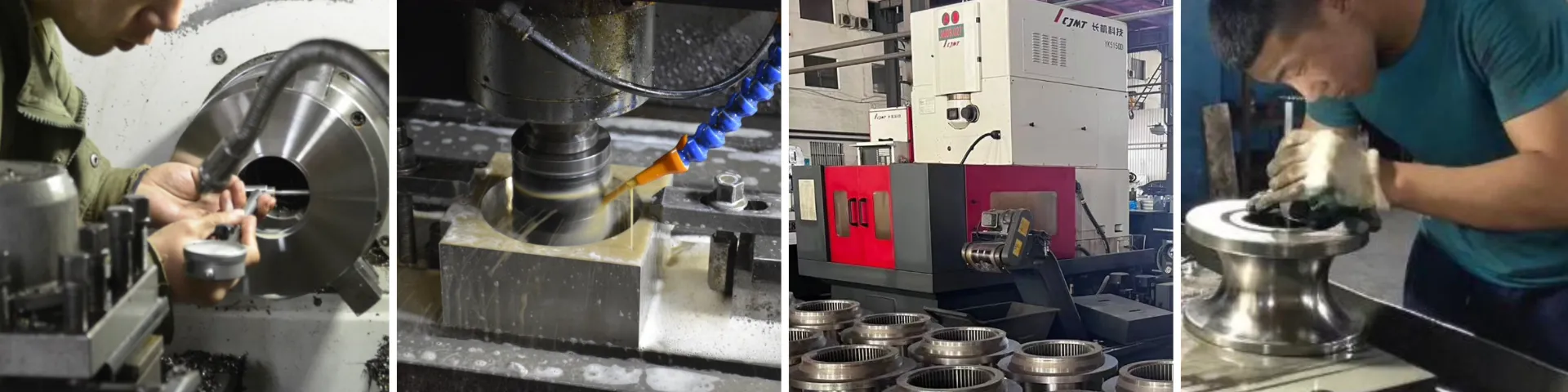

During high-frequency welding of steel tubes, excess weld material often forms along the inner seam, creating internal burrs that can interfere with downstream processes or product quality. The inner burr removal knife is a critical tool designed to trim and smooth these internal weld protrusions in-line during tube production, especially for applications requiring high inner surface quality—such as in automotive tubing, furniture, and fluid transport systems.

Working Principle

The inner burr knife is typically installed after the welding section and before sizing. A precision-guided support mechanism feeds the knife head into the inner diameter of the tube, aligning it directly under the weld seam. As the tube continuously moves forward, the knife scrapes or shaves off the burr along the weld line. Some knife heads feature oscillating or rotary action to enhance trimming efficiency. Removed burr particles are discharged and collected via an external extraction system.

Key Specifications (customizable upon request)

-

Applicable Tube Diameter: Φ16 – Φ219 mm (larger sizes available)

-

Wall Thickness Range: 1.0 mm – 8.0 mm

-

Knife Material Options: Carbide steel, HSS (High-Speed Steel), Ceramic-coated

-

Offset Adjustment Range: ±3 mm (to align with weld seam position)

-

Knife Mounting System: Mechanical locking / Spring preload / Pneumatic-assisted

-

Cooling Options: Air-cooled / Water-cooled / Dry-cutting (depending on application)

Common Questions & Answers

Q1: Is burr removal always necessary?

Not always. For light-wall or general-purpose tubing, internal deburring may not be required. However, it's recommended for structural or high-spec applications.

Q2: How long does the knife last?

The knife is a consumable. HSS or carbide blades typically last 1–3 weeks depending on speed, material, and maintenance. Keep spare sets available for continuous operation.

Q3: Does the knife require precise weld alignment?

Yes. Poorly aligned or inconsistent welds can cause blade deflection or breakage. Weld quality should be stable before applying internal burr removal.

Q4: Is the knife easy to replace?

Yes. Most knife holders are designed for quick change, with replacement typically taking just a few minutes.

Usage Tips

-

Always align the knife precisely with the weld seam before operation.

-

For automated lines, use seam-tracking systems to optimize blade positioning.

-

If scratching or tube wall damage occurs, inspect blade sharpness and angle settings.

-

When changing tube diameters, use matching knife heads or inserts for best results.

معدات العلاقات

نحن نوفر جميع المعدات لقسم دخول مصنع الأنابيب:

سيارة ملفوفة

آلة فك اللفات ذات الرأس المفرد والمزدوج وآلة فك اللفات الهيدروليكية والهوائية

مقشرة وذراع تثبيت للأسفل

آلة التسوية

ماكينة قص و لحام أوتوماتيكية و نصف أوتوماتيكية

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

قسم تشطيب مطحنة الأنابيب

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

قطع الغيار للاختيار

تنطبق قطع الغيار لدينا على:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

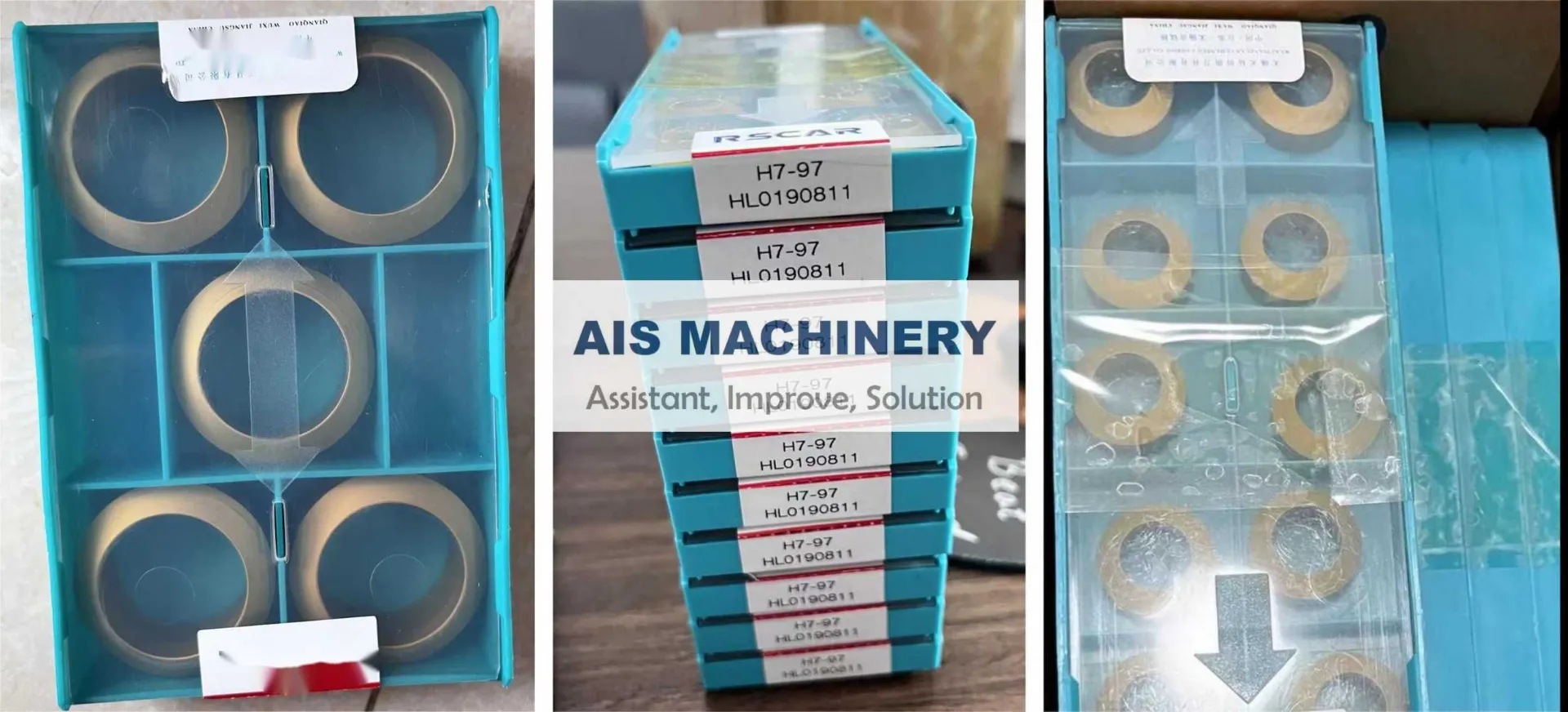

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

شهادة لدينا

خدمتنا

لماذا تختارنا؟

التكنولوجيا الرائدة، الجودة الموثوقة، الخدمة الممتازة!

تصميم مثالي، اختر مادة عالية الجودة!

ضمان عملية المعالجة الحرارية!

اقتران الترس المخروطي الحلزوني والترس الأسطواني والتكربن.

إخماد أسنان التروس.

نظام قيادة مستقر وفعال وقابل للارتداء مع ضوضاء أقل.

دقة عالية ومقاومة للتآكل وعمر طويل للبكرات.

يتم وضع جميع المخرطات الآلية والأخاديد الرئيسية وطحنها بواسطة CNC.

خدمتنا

خدمة ما قبل البيع

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

خدمة ما بعد البيع

1. سنقوم بتسليم الجهاز وتقديم المستندات في الوقت المحدد للتأكد من حصولك على الجهاز بسرعة

2. عند الانتهاء من شروط التحضير، سيذهب فريق مهندسي خدمة ما بعد البيع السريع والمهني إلى مصنعك لتثبيت الماكينة، وسيقدم لك دليل التشغيل، وتدريب موظفيك حتى يتمكنوا من تشغيل الماكينة بشكل جيد.

3. نحن نقدم ضمان لمدة عام واحد والدعم الفني مدى الحياة.

4. موظفون مدربون جيدًا وذوي خبرة للإجابة على جميع استفساراتك باللغتين الإنجليزية والصينية

5.24 ساعة لاستجابة المهندس.

6. ستكون علاقتك التجارية معنا سرية بالنسبة لأي طرف ثالث.

ضبط الجودة

لدينا قسم الجودة الوحيد، الذي يتأكد من أن مادة المواد الخام جيدة، ويضمن تشغيل الماكينة بسلاسة.

هاتف: 86-15176910262

هاتف: 86-15176910262