Inner Burr Removal Knife for ERW Tube Mills

During high-frequency welding of steel tubes, excess weld material often forms along the inner seam, creating internal burrs that can interfere with downstream processes or product quality. The inner burr removal knife is a critical tool designed to trim and smooth these internal weld protrusions in-line during tube production, especially for applications requiring high inner surface quality—such as in automotive tubing, furniture, and fluid transport systems.

Working Principle

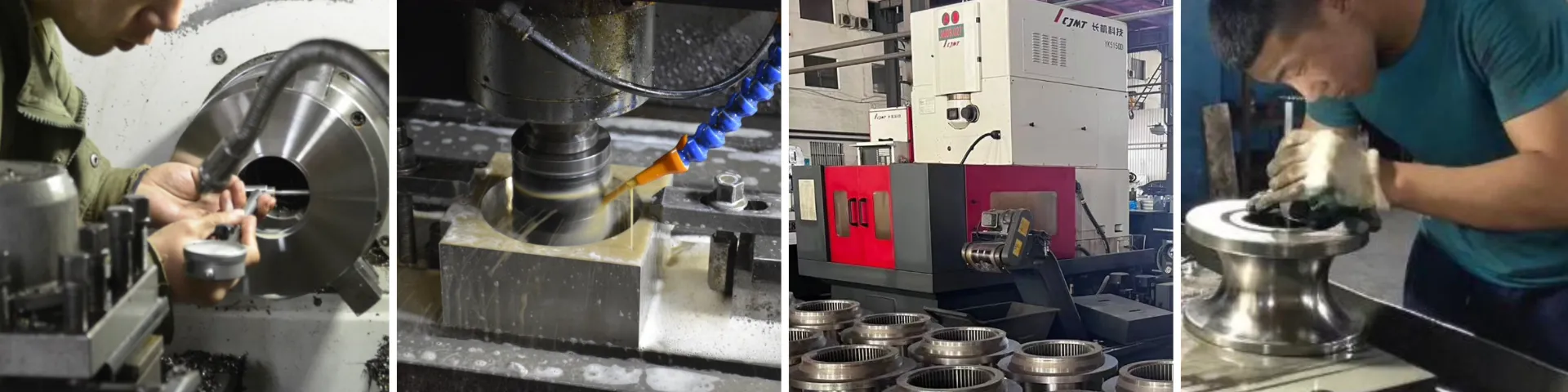

The inner burr knife is typically installed after the welding section and before sizing. A precision-guided support mechanism feeds the knife head into the inner diameter of the tube, aligning it directly under the weld seam. As the tube continuously moves forward, the knife scrapes or shaves off the burr along the weld line. Some knife heads feature oscillating or rotary action to enhance trimming efficiency. Removed burr particles are discharged and collected via an external extraction system.

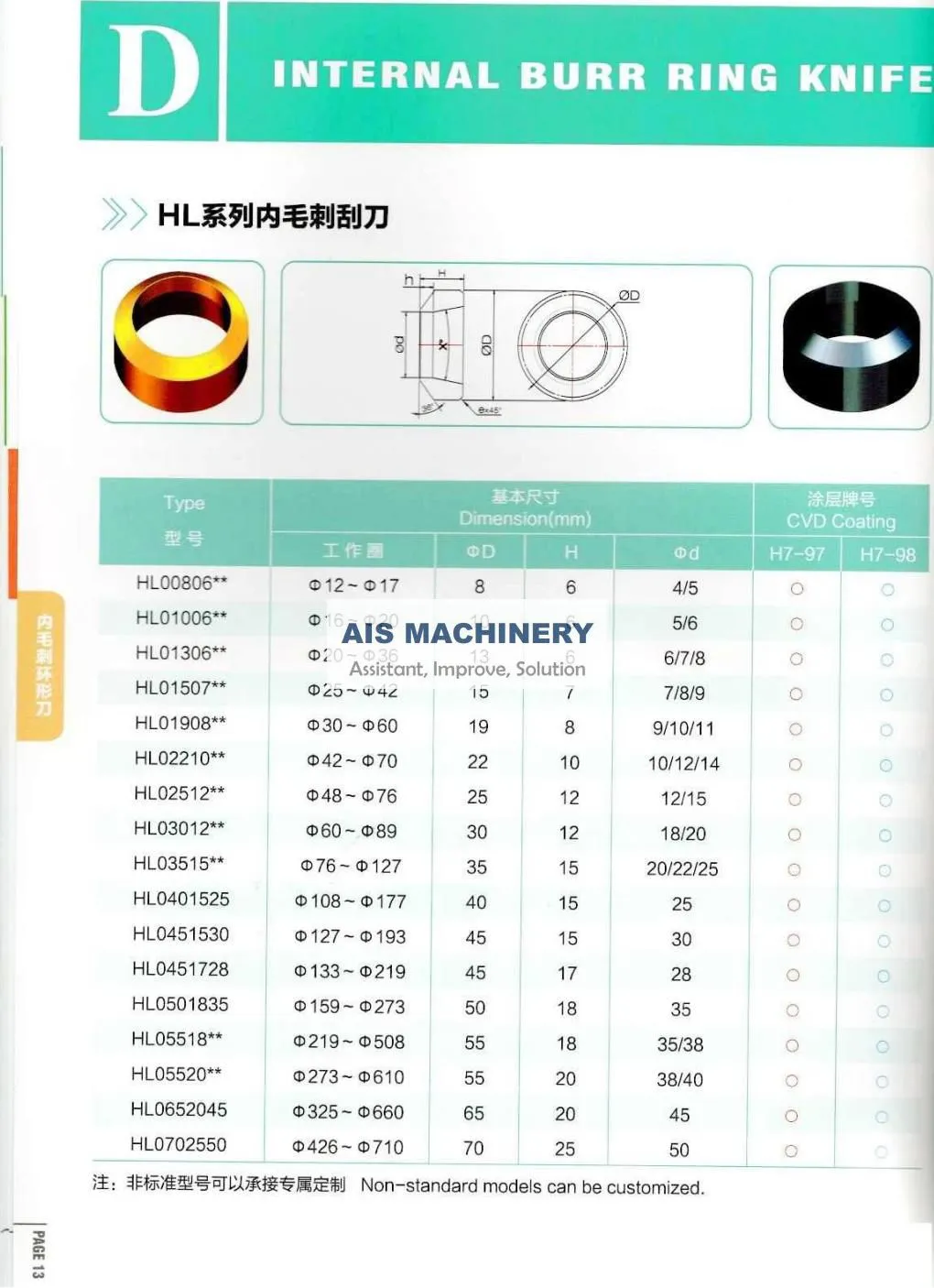

Key Specifications (customizable upon request)

-

Applicable Tube Diameter: Φ16 – Φ219 mm (larger sizes available)

-

Wall Thickness Range: 1.0 mm – 8.0 mm

-

Knife Material Options: Carbide steel, HSS (High-Speed Steel), Ceramic-coated

-

Offset Adjustment Range: ±3 mm (to align with weld seam position)

-

Knife Mounting System: Mechanical locking / Spring preload / Pneumatic-assisted

-

Cooling Options: Air-cooled / Water-cooled / Dry-cutting (depending on application)

Common Questions & Answers

Q1: Is burr removal always necessary?

Not always. For light-wall or general-purpose tubing, internal deburring may not be required. However, it's recommended for structural or high-spec applications.

Q2: How long does the knife last?

The knife is a consumable. HSS or carbide blades typically last 1–3 weeks depending on speed, material, and maintenance. Keep spare sets available for continuous operation.

Q3: Does the knife require precise weld alignment?

Yes. Poorly aligned or inconsistent welds can cause blade deflection or breakage. Weld quality should be stable before applying internal burr removal.

Q4: Is the knife easy to replace?

Yes. Most knife holders are designed for quick change, with replacement typically taking just a few minutes.

Usage Tips

-

Always align the knife precisely with the weld seam before operation.

-

For automated lines, use seam-tracking systems to optimize blade positioning.

-

If scratching or tube wall damage occurs, inspect blade sharpness and angle settings.

-

When changing tube diameters, use matching knife heads or inserts for best results.

PERALATAN HUBUNGAN

Kami menyediakan semua peralatan untuk bagian masuk pabrik tabung:

Mobil Koil

Pembuka Kepala Tunggal dan Ganda, Pembuka Kepala Hidrolik dan Pneumatik

Pengupas dan tahan lengan gulung

Mesin Perata

Mesin Pemotong dan Las Ujung Otomatis dan Semi Otomatis

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

BAGIAN FINISHING TUBE MILL

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

SUKU CADANG UNTUK DIPILIH

Suku Cadang Kami Berlaku:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

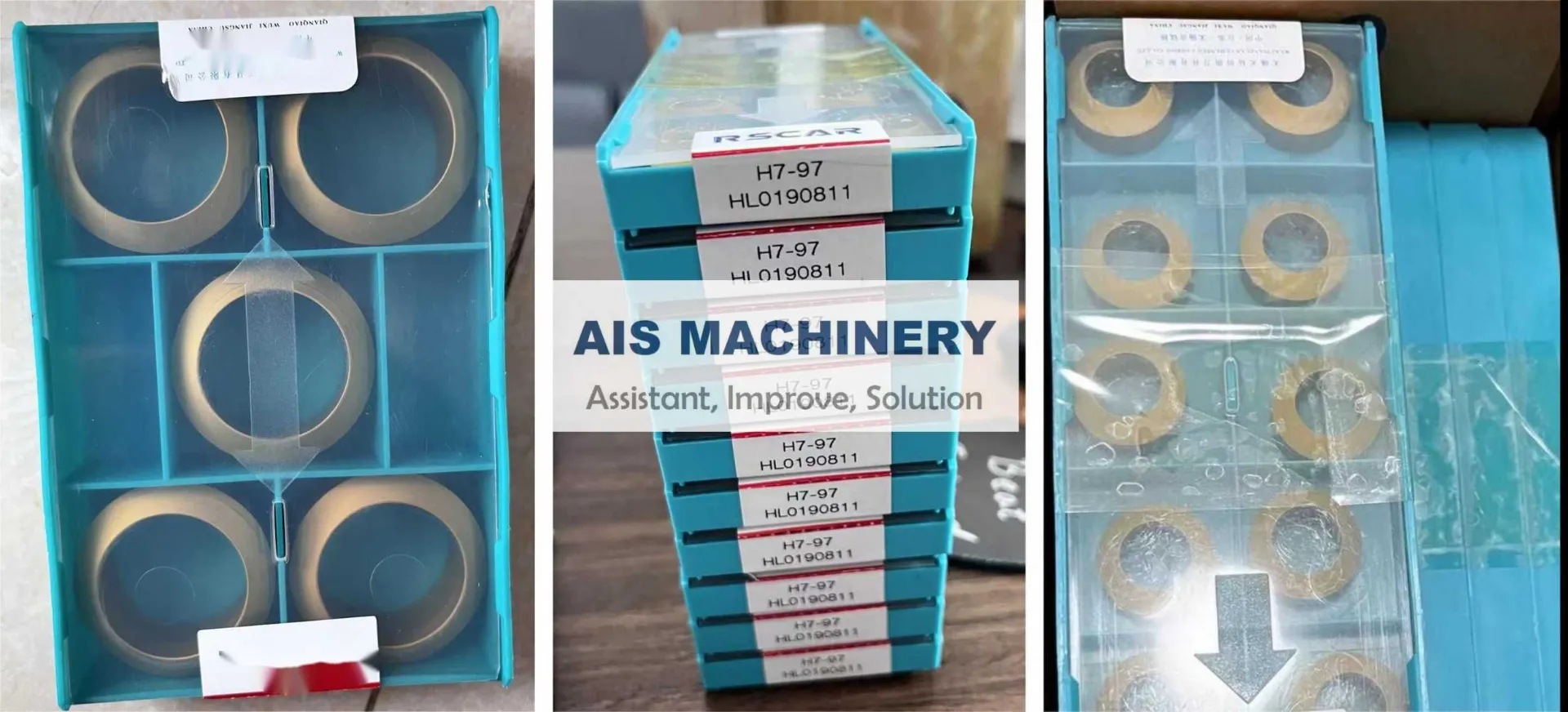

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

SERTIFIKAT KAMI

LAYANAN KAMI

Mengapa Memilih Kami?

Teknologi Terkemuka, Kualitas Andal, Layanan Luar Biasa!

Desain yang dioptimalkan, Pilihan material berkualitas tinggi!

Jaminan proses perlakuan panas!

Roda gigi spiral bevel, kopling roda gigi drum dan karburisasi.

Pendinginan gigi roda gigi.

Sistem penggerak stabil, efisien, dan dapat dipakai dengan tingkat kebisingan lebih rendah.

Ketahanan aus dengan presisi tinggi dan umur rol yang panjang.

Semua mesin Bubut, Alur Kunci diposisikan dan digiling oleh CNC.

Layanan Kami

Layanan pra-penjualan

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Layanan purna jual

1. Kami akan mengirimkan mesin dan memberikan dokumen tepat waktu untuk memastikan Anda bisa mendapatkan mesin dengan cepat

2. Setelah Anda menyelesaikan kondisi Persiapan, tim teknisi layanan purna jual kami yang cepat dan profesional akan pergi ke pabrik Anda untuk memasang mesin, memberi Anda manual pengoperasian, dan melatih karyawan Anda hingga mereka dapat mengoperasikan mesin dengan baik.

3. Kami menyediakan garansi satu tahun dan dukungan teknis seumur hidup.

4. Staf yang terlatih & berpengalaman akan menjawab semua pertanyaan Anda dalam bahasa Inggris dan Mandarin

5,24 jam untuk respon teknisi.

6.Hubungan bisnis Anda dengan kami akan dirahasiakan dari pihak ketiga mana pun.

Kontrol Kualitas

Kami memiliki departemen kualitas tunggal, yang memastikan bahan bakunya bagus, dan memastikan mesin berjalan lancar.

Telp:86-15176910262

Telp:86-15176910262