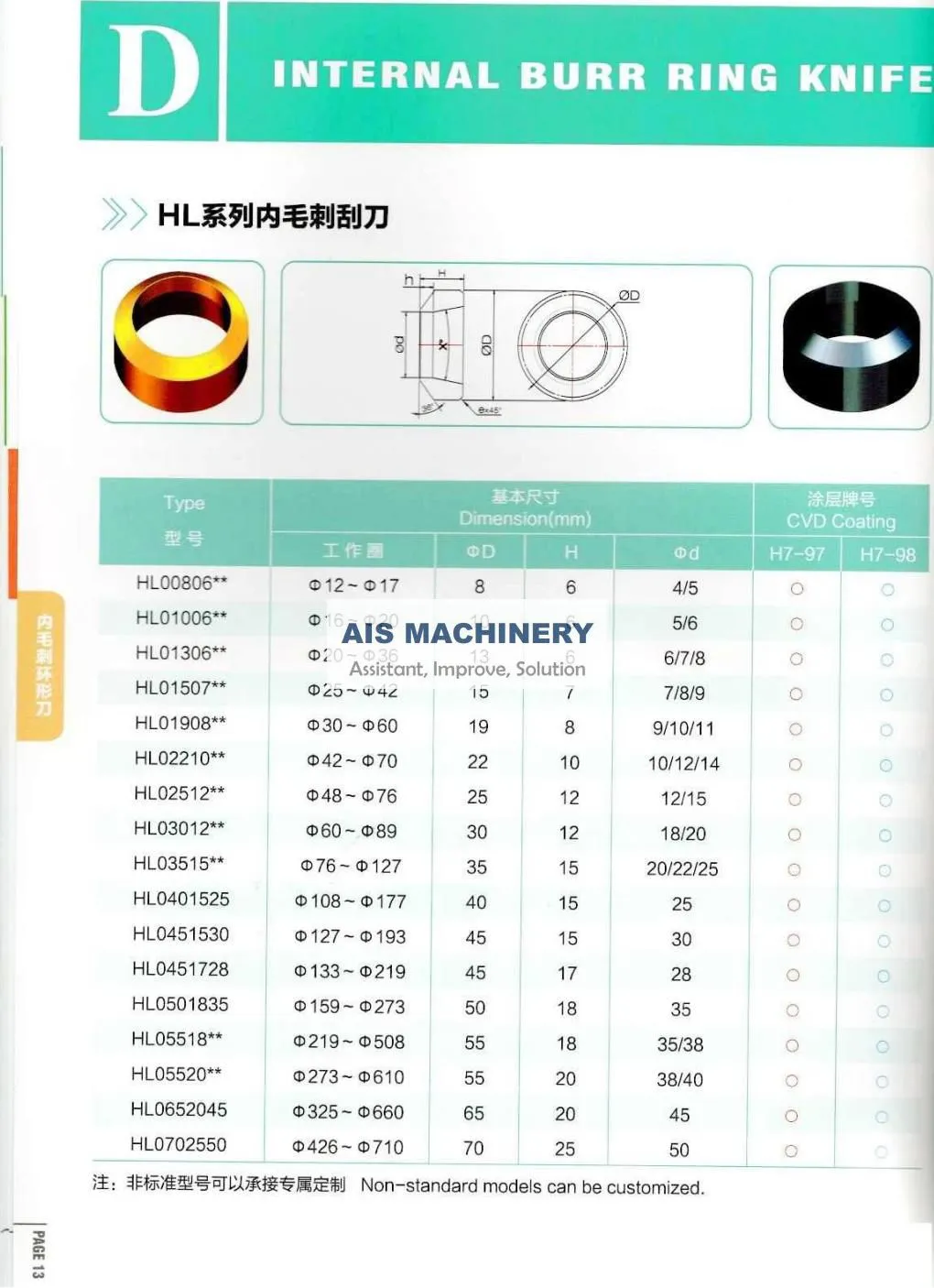

Inner Burr Removal Knife for ERW Tube Mills

During high-frequency welding of steel tubes, excess weld material often forms along the inner seam, creating internal burrs that can interfere with downstream processes or product quality. The inner burr removal knife is a critical tool designed to trim and smooth these internal weld protrusions in-line during tube production, especially for applications requiring high inner surface quality—such as in automotive tubing, furniture, and fluid transport systems.

Working Principle

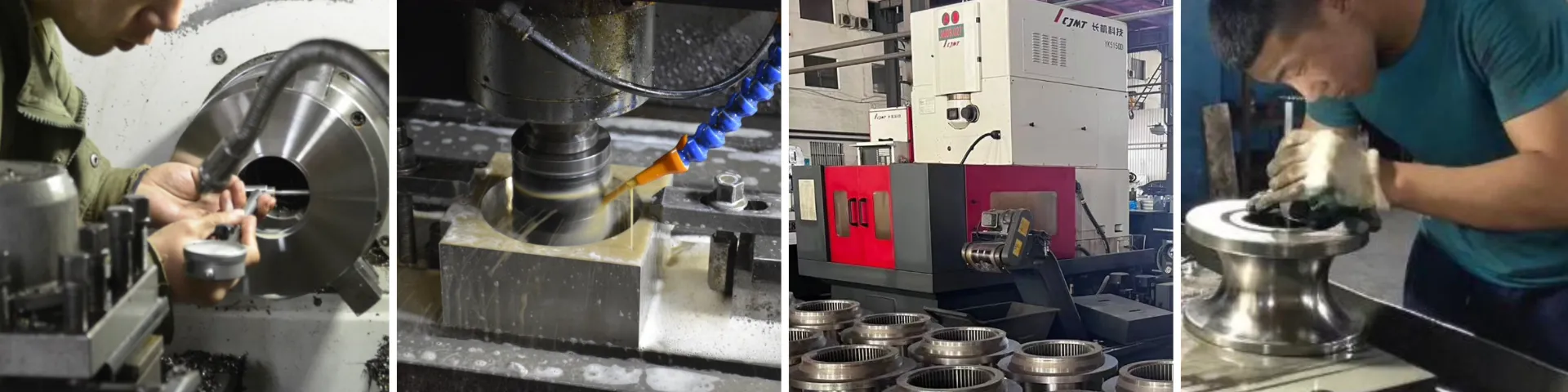

The inner burr knife is typically installed after the welding section and before sizing. A precision-guided support mechanism feeds the knife head into the inner diameter of the tube, aligning it directly under the weld seam. As the tube continuously moves forward, the knife scrapes or shaves off the burr along the weld line. Some knife heads feature oscillating or rotary action to enhance trimming efficiency. Removed burr particles are discharged and collected via an external extraction system.

Key Specifications (customizable upon request)

-

Applicable Tube Diameter: Φ16 – Φ219 mm (larger sizes available)

-

Wall Thickness Range: 1.0 mm – 8.0 mm

-

Knife Material Options: Carbide steel, HSS (High-Speed Steel), Ceramic-coated

-

Offset Adjustment Range: ±3 mm (to align with weld seam position)

-

Knife Mounting System: Mechanical locking / Spring preload / Pneumatic-assisted

-

Cooling Options: Air-cooled / Water-cooled / Dry-cutting (depending on application)

Common Questions & Answers

Q1: Is burr removal always necessary?

Not always. For light-wall or general-purpose tubing, internal deburring may not be required. However, it's recommended for structural or high-spec applications.

Q2: How long does the knife last?

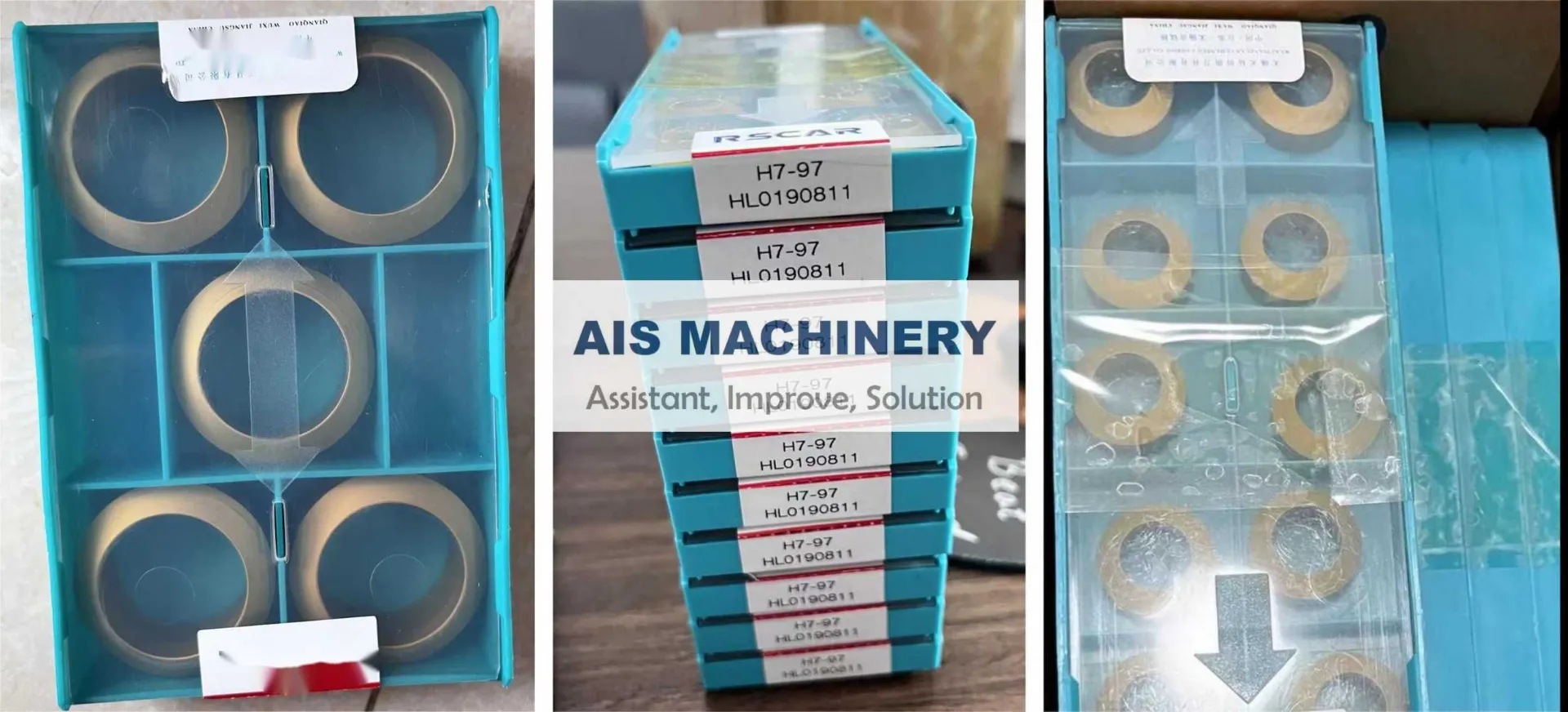

The knife is a consumable. HSS or carbide blades typically last 1–3 weeks depending on speed, material, and maintenance. Keep spare sets available for continuous operation.

Q3: Does the knife require precise weld alignment?

Yes. Poorly aligned or inconsistent welds can cause blade deflection or breakage. Weld quality should be stable before applying internal burr removal.

Q4: Is the knife easy to replace?

Yes. Most knife holders are designed for quick change, with replacement typically taking just a few minutes.

Usage Tips

-

Always align the knife precisely with the weld seam before operation.

-

For automated lines, use seam-tracking systems to optimize blade positioning.

-

If scratching or tube wall damage occurs, inspect blade sharpness and angle settings.

-

When changing tube diameters, use matching knife heads or inserts for best results.

COGNATIO ORNATUS

Nos omnem apparatum praebet ad sectionem molendini tubi viscus:

Coil Car

Singula et duplicata capita Un-coiler & hydraulica et pneumatica Un-coiler

Peeler et tenere in volumine arm

Machina adulatione

Automatic et Semi Auto Shearer & Butt Welder

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

TUBE MOLENDUM CONSUMMATIO SECTIO PRIMA

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

PARCE partes eligere

Nostris parce partes applicare:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

Testimonium nostrum

OPERA NOSTRA

Quid nos elige?

Ducens Technology, Reliable Quality, Excellent Service!

Optimized Design, High quality material select!

Caloris curatio processus spondet!

Calces cochleae revellere, orum calces copulatio et carburization.

Dentium calces exstingui.

Ratio acti stabilis, efficax et infatigabilis cum sonitu inferiori.

Summa subtilitate gerunt resistendo et longam tribulis vitam.

Tota machina Lathes, sulci Clavis a CNC cincta et molita sunt.

Our Service

Pre-venditionis officium

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Post-Sales ministerium

1. Nos machinam trademus et documenta in tempore praebebunt ut machinam celeriter efficere possis

2. Praeparatio condiciones cum consummaveris, Ieiunium et professio nostra postsales servitii fectum ibit ad officinam tuam ut machinam instituat, manualem operantem tibi tribuat, et operarium tuum exerceat donec machinam bene operari possint.

3. Nos unum annum warantum et diuturnum technicum subsidium praebent.

4.Bene peritus & peritus baculus respondeat omnibus tuis quaestionibus Anglice et Sinice

5 .24 horae ad fectum responsum.

6. Negotium tuum cum nobis communicatio alicui tertiae parti secretior erit.

Qualitas Imperium

Unicum qualitatem habemus, quae materiam rudium materiarum bonam fac, et machinam nonumyter curet.

Tel:86-15176910262

Tel:86-15176910262