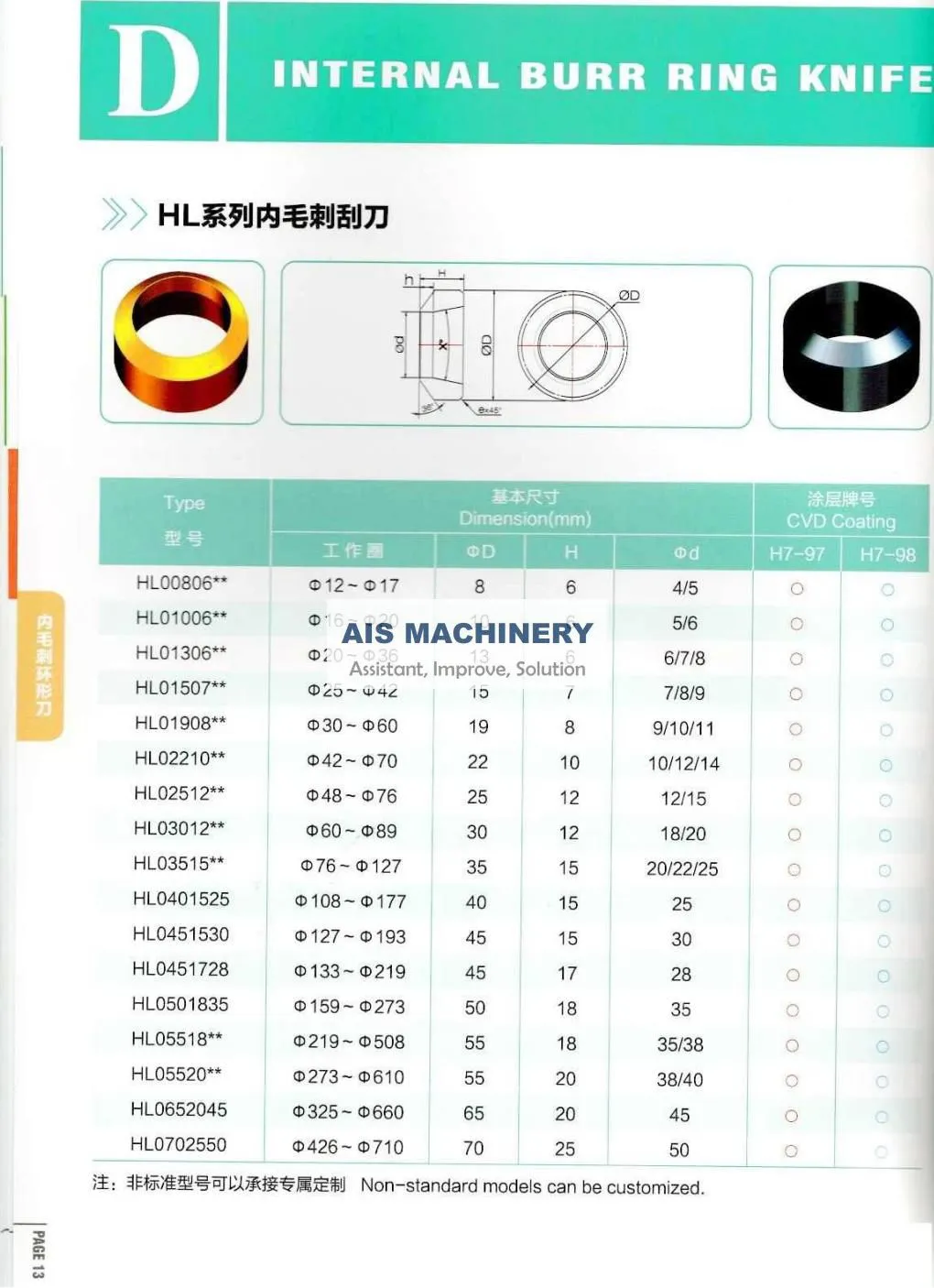

Inner Burr Removal Knife for ERW Tube Mills

During high-frequency welding of steel tubes, excess weld material often forms along the inner seam, creating internal burrs that can interfere with downstream processes or product quality. The inner burr removal knife is a critical tool designed to trim and smooth these internal weld protrusions in-line during tube production, especially for applications requiring high inner surface quality—such as in automotive tubing, furniture, and fluid transport systems.

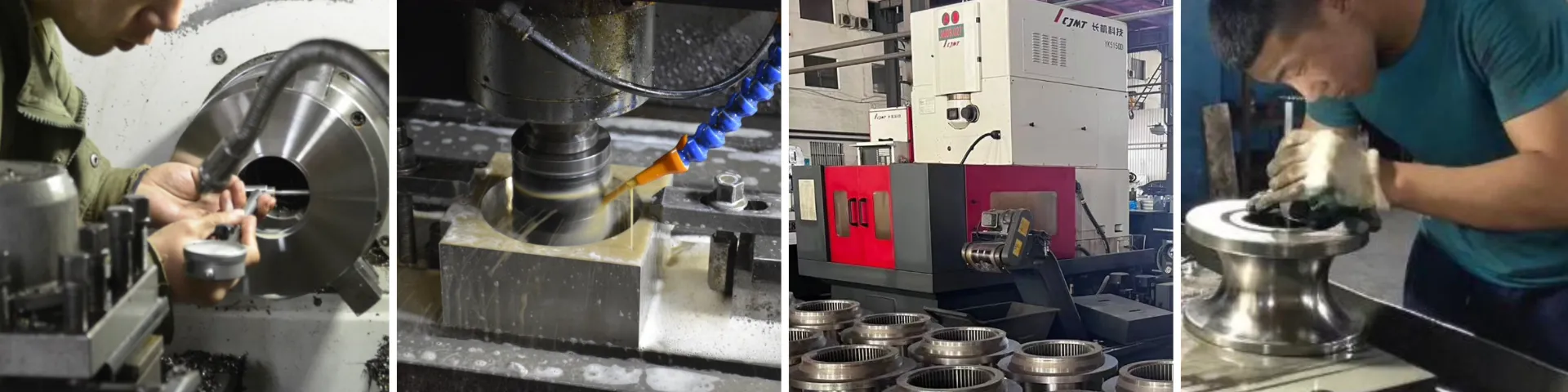

Working Principle

The inner burr knife is typically installed after the welding section and before sizing. A precision-guided support mechanism feeds the knife head into the inner diameter of the tube, aligning it directly under the weld seam. As the tube continuously moves forward, the knife scrapes or shaves off the burr along the weld line. Some knife heads feature oscillating or rotary action to enhance trimming efficiency. Removed burr particles are discharged and collected via an external extraction system.

Key Specifications (customizable upon request)

-

Applicable Tube Diameter: Φ16 – Φ219 mm (larger sizes available)

-

Wall Thickness Range: 1.0 mm – 8.0 mm

-

Knife Material Options: Carbide steel, HSS (High-Speed Steel), Ceramic-coated

-

Offset Adjustment Range: ±3 mm (to align with weld seam position)

-

Knife Mounting System: Mechanical locking / Spring preload / Pneumatic-assisted

-

Cooling Options: Air-cooled / Water-cooled / Dry-cutting (depending on application)

Common Questions & Answers

Q1: Is burr removal always necessary?

Not always. For light-wall or general-purpose tubing, internal deburring may not be required. However, it's recommended for structural or high-spec applications.

Q2: How long does the knife last?

The knife is a consumable. HSS or carbide blades typically last 1–3 weeks depending on speed, material, and maintenance. Keep spare sets available for continuous operation.

Q3: Does the knife require precise weld alignment?

Yes. Poorly aligned or inconsistent welds can cause blade deflection or breakage. Weld quality should be stable before applying internal burr removal.

Q4: Is the knife easy to replace?

Yes. Most knife holders are designed for quick change, with replacement typically taking just a few minutes.

Usage Tips

-

Always align the knife precisely with the weld seam before operation.

-

For automated lines, use seam-tracking systems to optimize blade positioning.

-

If scratching or tube wall damage occurs, inspect blade sharpness and angle settings.

-

When changing tube diameters, use matching knife heads or inserts for best results.

ALOQA QUVVATLARI

Biz quvur tegirmonining kirish qismiga barcha jihozlarni taqdim etamiz:

Bobinli avtomobil

Yagona va ikki boshli sarg'ish va gidravlik va pnevmatik sarg'ish

Peel va rulonli qo'lni ushlab turing

Yassilash mashinasi

Avtomatik va yarim avtomatik qirqimchi va payvandchi

Vertical Cage Accumulator & Horizontal Loop Accumulator & Landing Horizontal Spiral Loop Accumulator

QUVUR TEGIRMASINI TUGLASH BO'limi

We provides all equipment to tube mill Finishing section:

1. Eddy current machine

2. Seam annealing machine

3. Straightener machine

4. Chamfer and end facer machine

5. Hydro Tester machine

6. Threading machine

7. Painting and oil machine

8. Automatic bundle and package machine

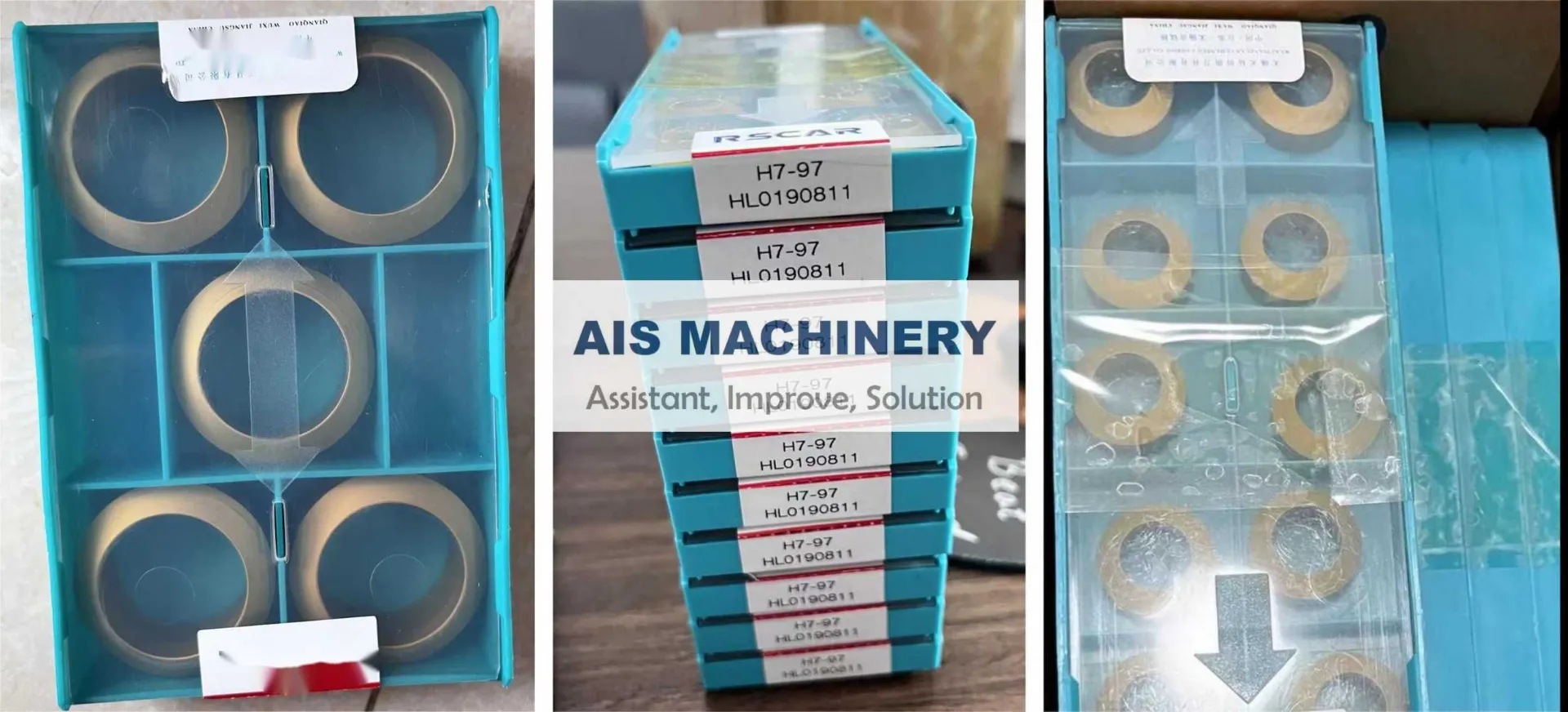

TANLASH UCHUN EHTIYOT QISMLAR

Bizning ehtiyot qismlarimiz qo'llaniladi:

1. Roller, Mould, Cr12, Cr12Mov material, D2,D3 material

2. Ferrite, Impeder, Fiberglass tube

3. HSS saw blades, TCT Saw blades, Friction saw blades

4. OD burr remove inserts, ID burr remover inserts

5. HF welder Induction Coil and other HF welder spare parts

6. Copper tube for induction Coil, PTFE pipe for Induction Coil

7. Mosfet, Boards

8. Steel pipe Strapping machine

9. Zinc Spray Machine, Zinc wire, Zinc spray gun

BIZNING SERTIFIKAT

BIZNING XIZMAT

Nima uchun bizni tanlaysiz?

Etakchi texnologiya, ishonchli sifat, zo'r xizmat!

Optimallashtirilgan dizayn, yuqori sifatli materialni tanlang!

Issiqlik bilan ishlov berish jarayoni kafolati!

Spiral konusli tishli, barabanli tishli ulanish va karbürizatsiya.

Tishli tishlarni o'chirish.

Boshqariladigan tizim barqaror, samarali va past shovqin bilan taqiladigan.

Yuqori aniqlikdagi aşınmaya bardoshli va rulonlarning uzoq umri.

Barcha dastgoh stanoklari, kalit yivlari CNC tomonidan joylashtirilgan va frezalangan.

Bizning xizmatimiz

Sotishdan oldingi xizmat

1. We can provide machine running videos for reference

2. We will recommend the most suitable equipment according to the needs of customers

3. We can provide the layout of the factory

4. We welcome customers to visit our factory

Sotishdan keyingi xizmat

1.Mashinani tezda olishingizga ishonch hosil qilish uchun biz mashinani yetkazib beramiz va hujjatlarni o'z vaqtida taqdim etamiz

2. Tayyorgarlik shartlarini tugatgandan so'ng, bizning tez va professional sotuvdan keyingi xizmat ko'rsatish bo'yicha muhandis jamoamiz mashinani o'rnatish uchun zavodingizga boradi, sizga foydalanish qo'llanmasini beradi va ishchingizni mashinani yaxshi boshqara olmaguncha o'rgatadi.

3.Biz bir yillik kafolat va umrbod texnik yordamni taqdim etamiz.

4. Yaxshi o'qitilgan va tajribali xodimlar sizning barcha so'rovlaringizga ingliz va xitoy tillarida javob berishlari kerak

Muhandis javobi uchun 5 .24 soat.

6.Biz bilan bo'lgan biznes munosabatlaringiz har qanday uchinchi tomon uchun maxfiy bo'ladi.

Sifat nazorati

Bizda yagona sifat bo'limi mavjud bo'lib, u xomashyo materialining yaxshi ekanligiga ishonch hosil qiladi va mashinaning muammosiz ishlashini ta'minlaydi.

Tel: 86-15176910262

Tel: 86-15176910262