-

Tel:86-15176910262

Tel:86-15176910262

-

Search

Precision Tube Mill Rolls Durable & Customized Solutions

Mai . 10, 2025 08:10

- Overview of Tube Mill Rolls in Modern Manufacturing

- Technical Advancements Driving Performance

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Industrial Needs

- Case Studies: Success Stories Across Industries

- Maintenance Strategies for Extended Roll Lifespan

- Choosing the Right Tube Mill Rolls Manufacturer

(tube mill rolls)

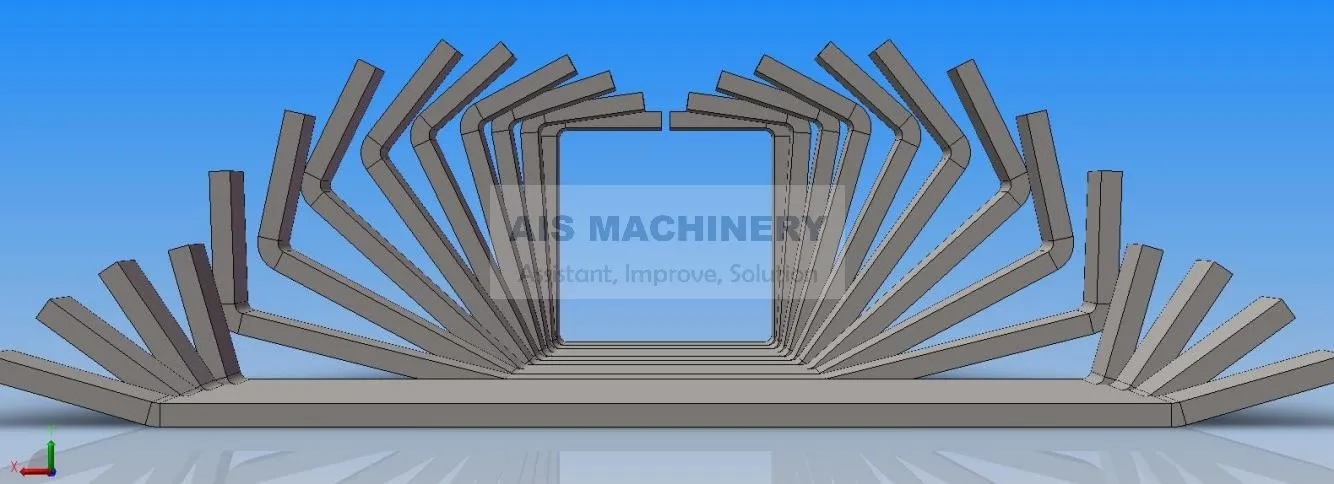

Understanding the Role of Tube Mill Rolls in Production

Tube mill rolls are critical components in the manufacturing of ERW (Electric Resistance Welded) pipes, responsible for shaping, forming, and welding metal strips into precise tubular profiles. These rolls account for 30-40% of a mill’s operational efficiency, directly influencing output quality and energy consumption. High-grade rolls reduce downtime by 22%, according to a 2023 industry report, making material selection and engineering precision paramount.

Technical Innovations Enhancing Durability

Modern tube mill rolls

leverage advanced alloys like H13 tool steel and tungsten carbide coatings, increasing wear resistance by 50% compared to traditional materials. CNC grinding ensures tolerances within ±0.002 mm, critical for producing pipes with diameters up to 24 inches. Heat treatment processes like induction hardening further extend service life by 35%, reducing replacement cycles from 6 months to 9 months in high-speed ERW mills.

Manufacturer Comparison: Performance Metrics

| Manufacturer | Hardness (HRC) | Max. Speed (m/min) | Price Range (USD) |

|---|---|---|---|

| Manufacturer A | 58-62 | 120 | $8,500-$12,000 |

| Manufacturer B | 60-64 | 150 | $10,200-$14,500 |

| Manufacturer C | 62-66 | 180 | $11,800-$16,000 |

Tailored Solutions for Complex Applications

Custom-designed rolls address challenges in producing non-standard profiles, such as square tubes or hydraulic cylinders. For instance, a recent project required rolls with 0.5 mm micro-grooves to process stainless steel 316L strips, achieving a 98.7% weld integrity rate. Modular roll systems now enable rapid configuration changes, cutting setup time by 40% for mills handling multiple product lines.

Industry-Specific Success Metrics

In the automotive sector, optimized rolls reduced material waste by 18% during exhaust pipe production. A European energy contractor reported a 27% increase in API 5L-grade pipe output after upgrading to forged steel rolls. These results highlight how precision engineering aligns with ROI goals, particularly when ERW tube mill price considerations factor in long-term operational savings.

Proactive Maintenance for Cost Efficiency

Implementing predictive maintenance schedules can reduce roll replacement costs by $15,000 annually per mill. Key practices include ultrasonic testing for subsurface cracks and laser alignment checks every 500 operating hours. Using synthetic lubricants with anti-spatter additives further extends polishing intervals by 60%, maintaining surface finish below 0.8 μm Ra.

Selecting a Reliable Tube Mill Rolls Manufacturer

Partnering with ISO 9001-certified manufacturers ensures adherence to global quality benchmarks. Top-tier providers offer 18-24 month warranties, backed by finite element analysis (FEA) simulations to validate roll designs. Evaluate suppliers based on lead times (ideally under 6 weeks), in-house metallurgical labs, and field support for urgent recalibration—critical factors for mills targeting ≤0.1% defect rates.

(tube mill rolls)

FAQS on tube mill rolls

Q: What factors determine the quality of tube mill rolls?

A: Quality depends on material composition, heat treatment precision, and surface finish. Reputable manufacturers use high-grade alloys and advanced hardening techniques. Consistent dimensional accuracy ensures optimal performance in tube-forming processes.

Q: How to choose a reliable tube mill rolls manufacturer?

A: Evaluate industry experience, certifications (ISO, ASTM), and client testimonials. Prioritize manufacturers offering custom engineering solutions and after-sales support. Verify their capability to meet specific production requirements and delivery timelines.

Q: What's the price range for ERW tube mill equipment?

A: ERW tube mill prices range from $200,000 to $2M+ depending on automation level and production capacity. Roll quality, auxiliary systems (welding, cutting), and brand reputation significantly impact costs. Custom configurations typically incur higher investments.

Q: How often should tube mill rolls be maintained?

A: Perform visual inspections after every production shift. Schedule professional regrinding every 3-6 months based on usage intensity. Proper lubrication and alignment checks between runs extend roll lifespan by 30-40%.

Q: Why choose ERW tube mill models over alternative technologies?

A: ERW mills offer superior weld consistency for high-speed production of structural tubes. They provide energy efficiency through solid-state welding technology. Modern ERW systems enable seamless diameter adjustments for multi-product manufacturing flexibility.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!