High-Frequency Induction Coil FAQs

What is an induction coil in welded pipe production?

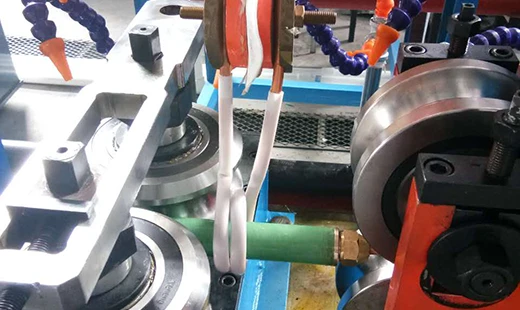

An induction coil is a key component in the high-frequency welding process used in welded pipe production. It generates high-frequency electromagnetic fields that induce currents in the pipe, which causes the pipe to heat up at specific areas, typically at the edges, to the required welding temperature. This enables the pipe to be welded together efficiently and with high quality.

What are the advantages of using an induction coil in welding?

Precise heating: The induction coil provides localized, precise heating to the pipe, ensuring uniform weld quality.

High efficiency: It enables rapid heating, reducing overall production time and energy consumption.

Improved weld quality: Induction heating results in fewer defects and a stronger weld joint.

What materials can induction coils be used to weld?

Induction coils are commonly used in welding steel pipes, seamless pipes, and galvanized pipes. They are suitable for welding a variety of materials that can be efficiently heated through electromagnetic induction.

How do I determine the correct induction coil size for my pipe production?

The correct size of the induction coil depends on several factors:

The diameter and wall thickness of the pipe.

The material of the pipe (e.g., steel, aluminum, etc.).

The required welding temperature and welding speed.

By considering these factors, the induction coil can be customized to suit specific production needs.

What is the operating temperature range of an induction coil?

Induction coils are typically designed to operate at temperatures up to 500°C or higher, depending on the cooling system and the coil's material. The coil is often equipped with a cooling system (usually water-cooled) to ensure safe operating temperatures during high-frequency welding.

関連製品

関連ニュース

メッセージを送信

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!