1. Equipment Composition

| No. |

Equipment Name |

Function Description |

| 1 |

Hydraulic Coil Car |

Coil loading and centering |

| 2 |

Hydraulic Uncoiler |

Decoiling with auto tensioning |

| 3 |

Shear & Butt Welder |

Coil joint welding to reduce downtime |

| 4 |

Accumulator/Looping System |

Buffer storage for continuous production |

| 5 |

Forming Mill (Pre-forming + Fin forming) |

Gradual bending of steel strip into round tube |

| 6 |

High-Frequency Welder |

Solid-state HF welding for seam joining |

| 7 |

Inner/Outer Burr Remover |

Deburring of weld seam for better surface |

| 8 |

Water Cooling System |

Quick cooling to stabilize dimensions |

| 9 |

Sizing & Straightening |

Diameter control and roundness adjustment |

| 10 |

Flying Saw |

Automatic cutting to set lengths |

| 11 |

Run-out Table |

Pipe delivery and collection |

2. Technical Parameters

-

✅ Stable Forming – Precision roll design with optional quick-change system

✅ High-Efficiency Welding – Solid-state HF welding ensures strong and smooth seams

✅ Accurate Cutting – Servo flying saw guarantees clean cuts and length accuracy

✅ Smart Control – Centralized control panel with remote diagnostics

✅ Energy Efficient – Low noise, low maintenance, optimized power consumption.

4. Application Fields

-

-

Oil and gas pipelines

-

Steel structure tubes

-

Agricultural irrigation and drainage

-

Municipal low-pressure pipe networks

-

Conduit and protective tubing

-

Machinery and engineering structural tubing

-

5. Operation Tips

-

Ensure strip is clean and oil-free before forming

-

Weld edges should be well aligned to avoid weak welds

-

Regularly clean and inspect deburring tools

-

Lubricate and align the forming and sizing rolls

-

Replace flying saw blades timely for optimal performance

-

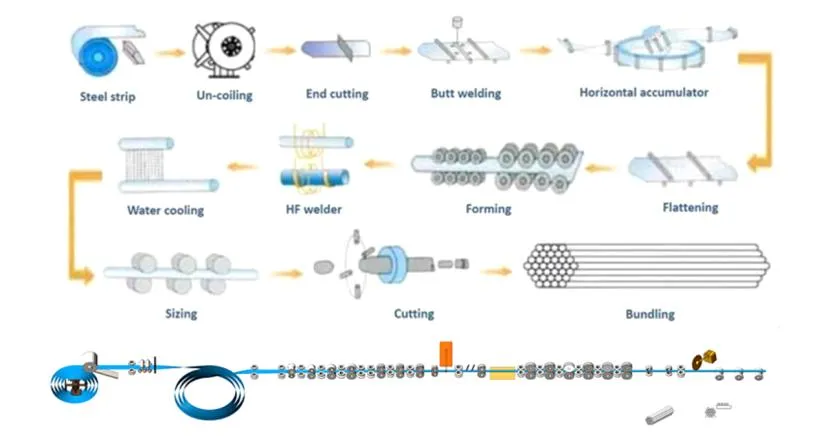

The Technical Flow of the Production Line

Uncoiling → Shearing & Welding → Looping Accumulator → Forming → HF Welding → Deburring → Cooling → Sizing & Straightening → Cutting → Run-out Table

6. Packaging and Transportation:

-

Main equipment is packed in steel-frame wooden crates with anti-rust treatment

-

Heavy components are fixed with brackets to prevent shifting during shipping

-

Customized reinforcement plans ensure safe delivery

-

Installation drawings and full documentation included

-

On-site installation guidance available upon request