-

Tel:86-15176910262

Tel:86-15176910262

-

Search

z purlin roll forming machine

Mar . 07, 2025 02:42

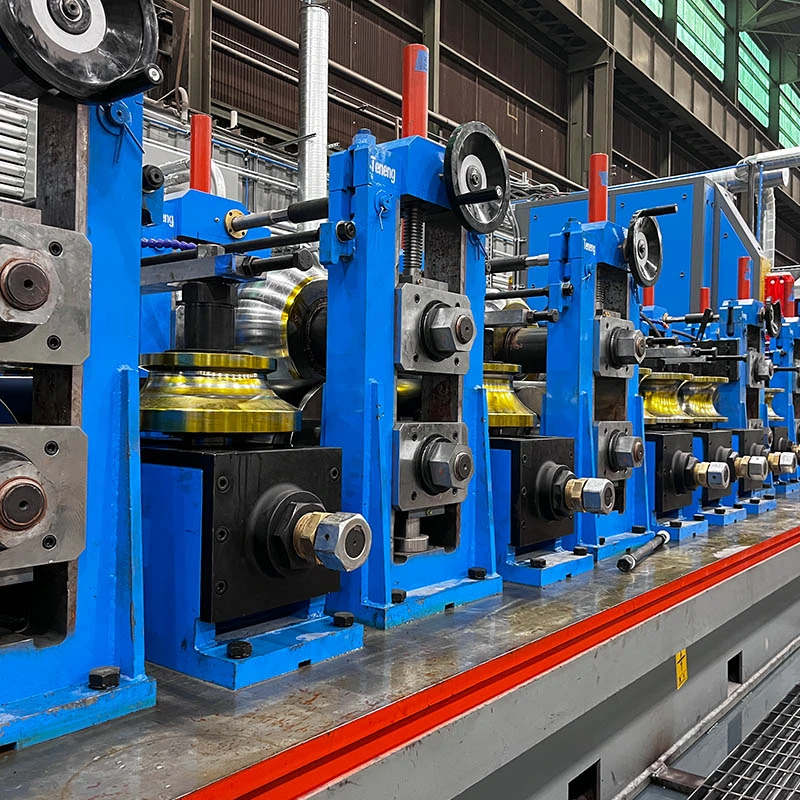

In the ever-evolving landscape of the construction industry, the demand for high-grade infrastructure materials is at an all-time high. One such indispensable component in modern construction is the C purlin, a crucial element in building frameworks. As the quest for quality and efficiency grows, the role of a C purlin roll forming machine becomes paramount. However, a critical question arises for contractors and builders alike what is the actual pricing of a C purlin roll forming machine, and what factors influence it?

5. Customizations and Upgrades Machines with options for customization to adapt to specific project requirements or future upgrade capabilities often incur additional costs. However, these customizations ensure the machine remains operable for an extended period, adapting to evolving market demands. Real-World Pricing Insights Drawing from verified industry sources and transactional data, base models of C purlin roll forming machines can range from approximately $20,000 to $50,000. More advanced models with sophisticated machinery and automation technologies can exceed $100,000. While this investment may seem substantial, experts attest to the value offered in terms of labor cost savings, increased operational efficiency, and minimal downtime. Consumer Testimonials and Expert Opinion Industry veterans frequently emphasize the importance of investing in quality machines over opting for cheaper alternatives. Testimonials from satisfied customers reveal that reliable machines significantly reduce operational hurdles, enabling timely project completions and the ability to undertake a diverse range of construction projects. Most professionals agree that the total cost of ownership is considerably lower when factoring in the reduced need for frequent repairs and part replacements. Ensuring Credibility and Trustworthiness For decision-makers contemplating the purchase of a C purlin roll forming machine, establishing a collaboration with reputable manufacturers or authorized distributors is vital. Conducting thorough due diligence, seeking recommendations from trusted industry peers, and assessing after-sales support services can ensure a purchase that aligns well with current and future business aspirations. In conclusion, while the upfront cost of a C purlin roll forming machine is an important consideration, the focus should be on the value it provides over its operational life. Investing in a machine that balances advanced technology, high-quality build, and reliable support is crucial for meeting the increasing demands of the construction industry efficiently.

5. Customizations and Upgrades Machines with options for customization to adapt to specific project requirements or future upgrade capabilities often incur additional costs. However, these customizations ensure the machine remains operable for an extended period, adapting to evolving market demands. Real-World Pricing Insights Drawing from verified industry sources and transactional data, base models of C purlin roll forming machines can range from approximately $20,000 to $50,000. More advanced models with sophisticated machinery and automation technologies can exceed $100,000. While this investment may seem substantial, experts attest to the value offered in terms of labor cost savings, increased operational efficiency, and minimal downtime. Consumer Testimonials and Expert Opinion Industry veterans frequently emphasize the importance of investing in quality machines over opting for cheaper alternatives. Testimonials from satisfied customers reveal that reliable machines significantly reduce operational hurdles, enabling timely project completions and the ability to undertake a diverse range of construction projects. Most professionals agree that the total cost of ownership is considerably lower when factoring in the reduced need for frequent repairs and part replacements. Ensuring Credibility and Trustworthiness For decision-makers contemplating the purchase of a C purlin roll forming machine, establishing a collaboration with reputable manufacturers or authorized distributors is vital. Conducting thorough due diligence, seeking recommendations from trusted industry peers, and assessing after-sales support services can ensure a purchase that aligns well with current and future business aspirations. In conclusion, while the upfront cost of a C purlin roll forming machine is an important consideration, the focus should be on the value it provides over its operational life. Investing in a machine that balances advanced technology, high-quality build, and reliable support is crucial for meeting the increasing demands of the construction industry efficiently.

Related Products

Related News

Send a Message

Dear customer, thank you for your attention! We provide high-quality machinery and equipment and look forward to your orders. Please inform us of your needs and we will respond quickly!