Unlocking Durability: The Power of Thermal Metal Spray Equipment

In industrial applications, the longevity and performance of components are paramount. This is where thermal metal spray equipment emerges as a critical technology, offering advanced surface engineering solutions to enhance material properties. From mitigating corrosion in harsh environments to restoring worn components, thermal spraying provides a cost-effective and highly efficient method to extend the operational lifespan of critical assets. Our focus delves into the comprehensive capabilities and strategic advantages of these systems, particularly highlighting our specialized Zinc Spray System, designed for superior protective coatings. The integrity of infrastructure across sectors like petrochemical, marine, and construction heavily relies on robust anti-corrosion strategies, making this technology indispensable for long-term sustainability and operational efficiency.

This innovative technology works by heating a coating material (wire or powder) to a molten or semi-molten state and propelling it onto a substrate. The impact of these particles creates a layered coating that bonds mechanically or metallurgically with the surface, imbuing it with new, enhanced properties. The precise control over parameters like temperature, particle velocity, and material composition allows for tailoring coatings to specific demands, addressing issues such as wear, erosion, and chemical degradation. Understanding the intricate balance of these variables is key to achieving optimal coating performance, distinguishing high-quality applications from mere superficial treatments.

Industry Trends and Technological Advancements

The thermal spray industry is undergoing significant transformation, driven by demands for increased automation, environmental sustainability, and the processing of advanced materials. Current trends indicate a shift towards more sophisticated control systems, enabling greater precision and repeatability in coating applications. Integrated robotics and AI-driven process optimization are becoming standard, reducing human error and enhancing overall efficiency. Furthermore, there's a growing emphasis on developing sustainable coating materials and processes that minimize environmental impact, aligning with global regulatory pressures and corporate responsibility initiatives.

Demand for advanced surface solutions is surging in sectors like renewable energy (wind turbines, solar panels), aerospace, and medical devices, where components operate under extreme conditions. This necessitates continuous innovation in both the coating materials themselves and the thermal metal spray equipment used to apply them. Manufacturers are focusing on creating systems capable of handling complex geometries and producing ultra-dense, low-porosity coatings. The integration of inline monitoring and feedback systems ensures real-time quality control, crucial for applications demanding zero defects and extended service life.

Advanced Control Panels for Precision Thermal Spraying

Manufacturing Process and Quality Standards of Thermal Spray Equipment

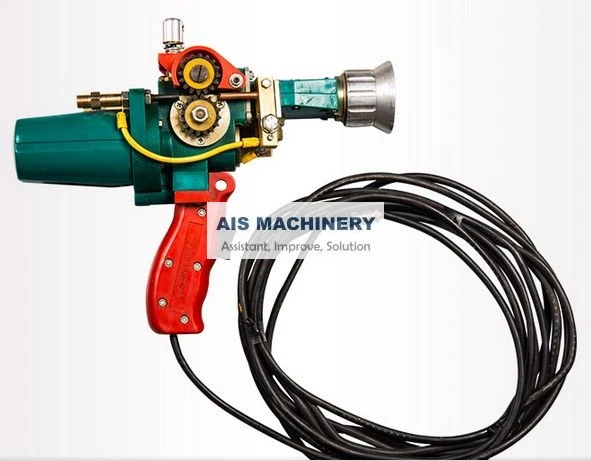

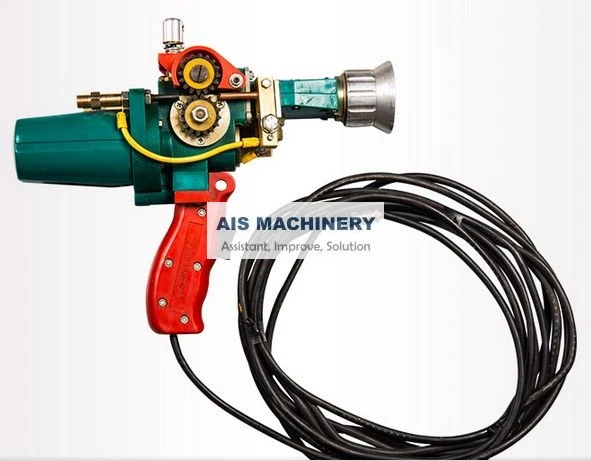

The reliability of thermal metal spray equipment begins with its own manufacturing process. Our Zinc Spray System, for instance, is built using high-grade stainless steel and specialized alloys for critical components, ensuring durability and resistance to wear. Key manufacturing processes include precision CNC machining for nozzles, wire feed mechanisms, and control interfaces, guaranteeing exact tolerances and consistent performance. Advanced forging and casting techniques are employed for high-stress parts, providing superior mechanical strength and extended operational life. This meticulous attention to detail at every stage of production prevents premature wear and ensures long-term reliability.

Rigorous quality control is embedded throughout our manufacturing pipeline. All components undergo multi-stage inspections, adhering to international standards such as ISO 9001 for quality management systems and ANSI standards for safety and performance. Pressure testing, electrical safety checks, and functional testing of the entire system are performed before dispatch, ensuring that each unit meets stringent operational parameters. Our thermal metal spray equipment is designed for a service life exceeding 15 years under typical industrial use, reflecting our commitment to enduring quality. These robust systems find applications in heavy equipment manufacturing, infrastructure projects, and specialized industrial service providers where reliability is non-negotiable.

Technical Parameters and Performance Capabilities

Understanding the technical specifications of thermal metal spray equipment is crucial for selecting the right system for specific industrial needs. Key parameters directly influence coating quality, application speed, and operational efficiency. The table below outlines typical ranges and crucial considerations for high-performance thermal spray systems, emphasizing factors that contribute to superior coating adhesion and durability. These specifications are engineered to deliver precise control over the atomization and deposition of coating materials, ensuring uniform thickness and optimal material utilization, which directly translates to cost savings and enhanced performance for the end-user.

| Parameter |

Typical Range / Value |

Impact on Performance |

| Power Input (Arc Spray) |

15-35 kW (Adjustable) |

Determines melt rate and spray velocity; higher power for denser coatings. |

| Wire Feed Speed |

0.5 - 15 m/min |

Controls deposition rate; crucial for uniform coating thickness. |

| Atomization Air Pressure |

0.4 - 0.7 MPa (60-100 PSI) |

Influences particle size, velocity, and coating density/porosity. |

| Coating Adhesion Strength (Zinc) |

> 10 MPa (ASTM C633) |

Indicates bond quality; critical for durability against mechanical stress. |

| Operating Temperature Range |

-40°C to +80°C (for coated parts) |

Ensures coating integrity across varied environmental conditions. |

| System Portability |

Mobile (e.g., cart-mounted) |

Facilitates on-site applications and flexibility. |

These specifications ensure that our Zinc Spray System delivers high-quality, dense coatings essential for robust corrosion protection. The precise control over voltage and current in our arc spray systems allows for optimal melting and atomization of zinc wire, resulting in a fine, uniform spray pattern. This capability minimizes material waste and maximizes deposition efficiency, making it an economically viable solution for large-scale surface treatment projects.

Application Scenarios and Strategic Advantages

The versatility of thermal metal spray equipment extends its application across a myriad of critical industrial sectors. Our Zinc Spray System, for example, is predominantly utilized for superior anti-corrosion protection on large steel structures, pipelines, and industrial machinery. In the petrochemical industry, it safeguards tanks, columns, and piping from aggressive chemical attack and atmospheric corrosion, significantly extending asset life. For the metallurgy sector, it provides durable coatings for structural steel components, reinforcing their resistance to environmental degradation. In water and drainage systems, thermal spray coatings protect critical infrastructure like bridges, dams, and water treatment plant components, ensuring operational integrity and public safety.

Beyond direct corrosion resistance, the advantages include energy savings and reduced maintenance costs. By preventing corrosion and wear, components require less frequent replacement or repair, translating to significant operational expenditure (OpEx) reductions. This extends the lifespan of capital-intensive equipment, leading to higher asset utilization and a more sustainable industrial footprint. The rapid application process minimizes downtime, which is crucial for continuous operations. Moreover, the ability to apply coatings on-site, even to existing structures, offers immense flexibility and reduces logistical complexities associated with off-site treatments. This comprehensive approach to asset protection underscores the long-term value delivered by high-quality thermal metal spray equipment.

On-site Application of Thermal Metal Spray for Infrastructure Protection

Comparing Thermal Spray Equipment Technologies

The landscape of thermal spray technologies includes various methods, each suited for specific applications and material types. Key technologies often compared are Flame Spray, Arc Spray, and High-Velocity Oxygen Fuel (HVOF). Flame spray, a traditional method, is versatile for many materials but typically produces more porous coatings. HVOF, known for its high particle velocity, creates dense, well-bonded coatings, ideal for wear resistance, often at higher capital costs. Our Zinc Spray System primarily utilizes the Twin Wire Arc Spray (TWAS) method. TWAS involves feeding two electrically charged wires into a gun, where an electric arc melts them. An atomizing gas then strips the molten metal from the wire tips and propels it onto the substrate.

| Feature |

Twin Wire Arc Spray (TWAS) |

HVOF Spray |

Flame Spray |

| Coating Density |

Medium to High |

Very High |

Low to Medium |

| Bond Strength |

High |

Very High |

Medium |

| Typical Application |

Corrosion Protection (Zinc, Aluminum) |

Wear & Erosion Resistance (Carbides, Superalloys) |

Dimensional Restoration, General Coatings |

| Cost-Effectiveness |

High (especially for large areas) |

Medium (higher initial investment) |

High (lower initial cost) |

The choice of thermal metal spray equipment largely depends on the specific coating requirements. TWAS systems, like our Zinc Spray System, offer an excellent balance of cost-effectiveness, high deposition rates, and robust coating quality, making them ideal for large-scale anti-corrosion applications where durability is key but extreme hardness is not the primary objective. Their efficiency and ability to handle large surfaces quickly provide a significant advantage in infrastructure projects and general industrial maintenance.

Customized Solutions and Project Integration

Recognizing that every industrial challenge is unique, we specialize in providing customized thermal metal spray equipment solutions tailored to specific project requirements. Our engineering team collaborates closely with clients to understand their operational environment, material specifications, and desired coating properties. This collaborative approach allows us to design and configure systems that integrate seamlessly into existing production lines or new facility setups. Whether it's a specialized robotic integration for automated coating of complex parts or a portable system for on-site maintenance in remote locations, our solutions are designed for optimal performance and efficiency.

Our expertise extends beyond merely supplying equipment; we offer comprehensive project integration services, including system layout, installation supervision, and operational training for your technical staff. This holistic support ensures that our clients can maximize the value of their investment and achieve superior coating results consistently. We also provide ongoing technical assistance and spare parts support, solidifying our role as a long-term partner in your surface engineering endeavors. This commitment to full-lifecycle support is a cornerstone of our service philosophy, reinforcing trust and ensuring operational continuity.

Tailored Thermal Spray Solutions for Diverse Industrial Needs

Application Case Studies and Success Stories

The tangible benefits of employing high-quality thermal metal spray equipment are best illustrated through real-world applications. In a significant infrastructure project involving a large bridge in a coastal region, traditional paint coatings struggled against the aggressive marine environment, requiring frequent reapplication. By implementing our Zinc Spray System, a 300-micron thick zinc coating was applied to critical steel elements. This solution not only provided superior cathodic protection, extending the maintenance cycle from 5 to over 20 years, but also significantly reduced long-term operational costs and minimized environmental impact from repeated repainting.

Another compelling case involved a major petrochemical plant experiencing severe corrosion on their storage tanks due to chemical exposure and high humidity. After assessing various options, they chose our thermal metal spray equipment for applying an aluminum-zinc alloy coating. The specialized coating resisted both the corrosive chemicals and the humid climate, leading to a projected doubling of the tank's service life and averting costly structural repairs or replacements. These examples underscore the strategic value of investing in robust thermal spray technology for long-term asset integrity and operational resilience, validating its efficacy in diverse, challenging industrial environments.

Our Authority and Trustworthiness in Thermal Spray Solutions

Our commitment to excellence is underpinned by a robust foundation of industry certifications and a proven track record. As a manufacturer of thermal metal spray equipment, we operate under an ISO 9001 certified quality management system, ensuring that every product leaving our facility adheres to the highest international standards for design, manufacturing, and testing. This certification is not merely a formality; it reflects our dedication to continuous improvement and client satisfaction. Our Zinc Spray System, along with other specialized equipment, is CE certified, guaranteeing compliance with European safety, health, and environmental protection requirements, enabling seamless deployment across global markets.

With over two decades of specialized experience in surface engineering and a portfolio of successful partnerships with leading industrial players, our authority in the field is well-established. We routinely conduct internal and third-party performance tests on our equipment and the resulting coatings, providing empirical data on adhesion strength, corrosion resistance, and wear characteristics. Our extensive service history and positive client feedback stand as testament to the reliability and effectiveness of our solutions. We pride ourselves on transparent communication and proactive support, fostering long-term relationships built on mutual trust and shared success.

Quality Assurance and Certifications for Our Thermal Metal Spray Equipment

Frequently Asked Questions (FAQ)

-

Q: What materials can be applied with your thermal metal spray equipment?

A: Our systems, including the Zinc Spray System, are primarily designed for metallic wires such as zinc, aluminum, zinc-aluminum alloys, and various steels. We can also provide tailored solutions for other specific material requirements based on application needs.

-

Q: What is the typical lead time for delivery?

A: Standard thermal metal spray equipment models typically have a lead time of 4-6 weeks from order confirmation. Customized solutions may require 8-12 weeks, depending on complexity. We maintain a robust logistics network to ensure timely and secure delivery worldwide.

-

Q: Do you offer training and after-sales support?

A: Absolutely. We provide comprehensive on-site or remote training for your operators and maintenance personnel. Our dedicated technical support team is available for troubleshooting, spare parts supply, and ongoing consultation to ensure optimal performance of your thermal metal spray equipment throughout its lifespan.

-

Q: What warranty is provided with your equipment?

A: Our thermal metal spray equipment comes with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options and service agreements are also available for enhanced peace of mind.

Conclusion: Investing in Long-Term Asset Integrity

The strategic deployment of high-quality thermal metal spray equipment represents a proactive investment in the longevity, efficiency, and safety of industrial assets. By providing superior protective coatings against corrosion, wear, and environmental degradation, these systems offer a compelling value proposition through reduced maintenance costs, extended operational lifespans, and enhanced overall performance. Our commitment to precision engineering, stringent quality standards, and comprehensive customer support ensures that our Zinc Spray System and other thermal spray solutions deliver unparalleled reliability and return on investment for B2B stakeholders.

Choosing the right thermal metal spray equipment is a pivotal decision that impacts long-term operational costs and environmental footprint. With a focus on advanced technology, customized solutions, and unwavering support, we stand ready to empower your industrial operations with robust and sustainable surface engineering capabilities. Partner with us to future-proof your critical infrastructure and maintain a competitive edge in demanding industrial landscapes.

References

- Davis, J. R. (Ed.). (2002). Handbook of Thermal Spray Technology. ASM International.

- Kuroda, S., Kawai, S., & Vardelle, A. (2018). Thermal Spraying: Fundamentals and Applications. Woodhead Publishing.

- Pawlowski, L. (2008). The Science and Engineering of Thermal Spray Coatings. John Wiley & Sons.

- Fauchais, P., & Vardelle, A. (2010). Thermal Spraying: State of the Art and Market Trends. Surface and Coatings Technology, 204(2), 229-239.

- Gartner, D. A. (2015). Thermal Spray Technology: Past, Present, and Future. Journal of Thermal Spray Technology, 24(7), 1187-1196.

Tel:86-15176910262

Tel:86-15176910262